- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V/220V

-

Dimension(L*W*H):

-

10000*2300*2700mm

-

Certification:

-

ASME

-

Power:

-

63 kw

-

Weight:

-

5500 KGs

-

Type:

-

Vulcanizing Autoclave

-

Model:

-

DN1500

-

DESIGN PRESSURE:

-

0.8mpa

-

Suitable:

-

15-22.5''

-

MATERIAL:

-

Carbon Steel

-

Service:

-

Installation

-

Warranty:

-

1 Year

-

PAYMENT:

-

T/T

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

MELION

-

Model Number:

-

ML-SERIES

-

Voltage:

-

380V/220V

-

Dimension(L*W*H):

-

10000*2300*2700mm

-

Certification:

-

ASME

-

Power:

-

63 kw

-

Weight:

-

5500 KGs

-

Type:

-

Vulcanizing Autoclave

-

Model:

-

DN1500

-

DESIGN PRESSURE:

-

0.8mpa

-

Suitable:

-

15-22.5''

-

MATERIAL:

-

Carbon Steel

-

Service:

-

Installation

-

Warranty:

-

1 Year

-

PAYMENT:

-

T/T

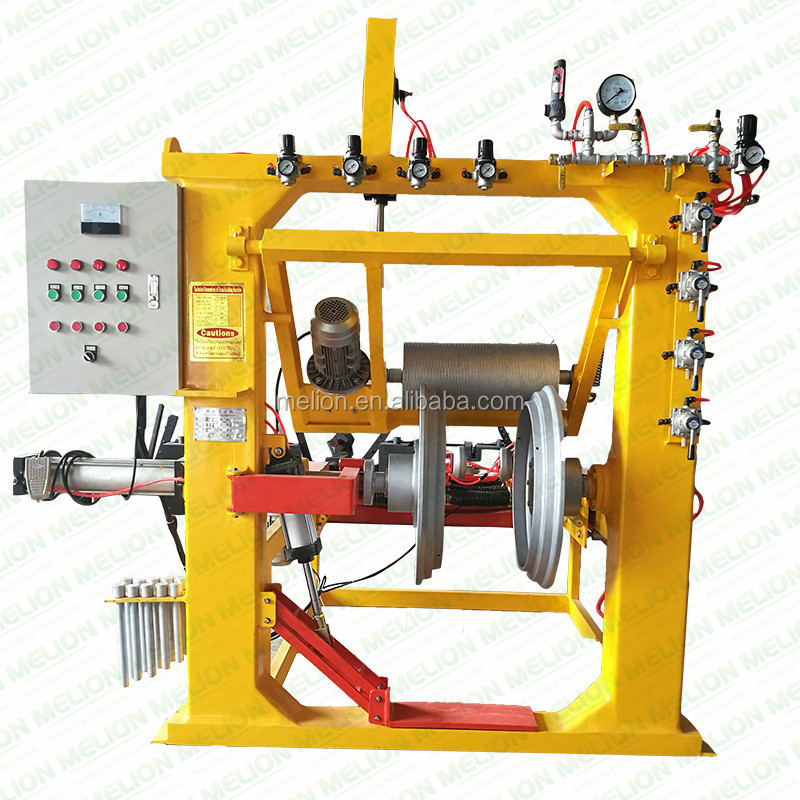

China full set Cold Precure Truck Tyre Retread Machines

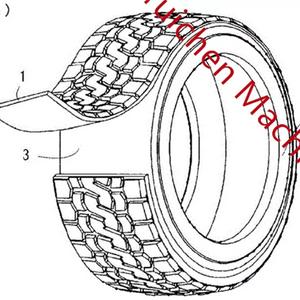

In the pre-cured technology, the tread is supplied to the retreading factory cured, with the tread pattern already in place. The treads are supplied in rolls of various lengths (typically 3.5 to 10 meters in length), or as rings that can be stretched onto the casing. In the application of both pre-cured methods, a bonding material, the cushion, is applied to the tread or the casing prior to the application of the tread.

1.

Conventional Process (also known as ‘mould cure’ or ‘hot cure’ process) – In this process an un-vulcanized rubber strip is applied on the buffed casing of the tire. This strip takes the pattern of the mould during the process of vulcanization.

2.Melion Precure Process (also known as melion ‘cold cure’) – In this process a tread strip, where the pattern is already pressed and precured is applied to the casing. It is bonded to the casing by means of a thin layer of specially compounded uncured rubber (known as cushion or bonding gum) which is vulcanized by the application of heat, pressure and time.

In the pre-cured rubber (cold process) retreading, better mileage is obtained than with the hot capping process.

The tire is inspected for cuts, ply separations, etc. and after inspection, it is repaired with repair compound or patches, and then buffed under inflated conditions to facilitate bonding. Thereafter, the tire is again inflated on an expandable hub and coated with vulcanizing cement on its buffed surface. A layer of bonding / cushion gum is applied around the surface of the tire. The trapped air between the layers is removed and the vulcanized tread strip is applied, its ends spliced and stitched.

After this operation, the expandable hubs are collapsed and the tire is deflated and removed for vulcanization. The tire is fitted on suitable rims and inflated with the use of a tube. The inflated tire is then slipped into an envelop and vulcanized in Melion curing chamber or autoclave at lower temperatures than is normally used for new tire vulcanization.

Tire Preparation-Melion

The buffing process provides a contaminant-free surface of uniform texture to allow adhesive of the new tread. During the buffing process, the casing is also brought to a uniform circumference, with the correct thyroidal radius and width, to accept the proper tread size for the casing.

After buffing and skiving the casing, a thin layer of contact adhesive is applied to the casing. This material usually referred to as cement, aids in the retread tire fabrication process and helps provide increased adhesion between the casing and the cushion. The cementing of the casings is optional, but widely used in retreading. Cements are solvent-or water based materials.

It is at this point that the majority of the repair to the casing is performed. The main purpose of repairing the casing is to restore the ability of the casing to maintain air pressure and to return mechanical properties of the casing to a level high enough to endure at least the next use life.

After the completion of the repairing of the casing, the tread can be applied. The application of the tread is referred to, as building the tire, and there are a number of variations to the building process.

The main components used in the tire building are the tread and cushion. The tread is supplied to the retread factory fully cured with the desired design and tread width. The back side of the tread is prepared at the manufacturer end by buffing with a wire brush drum and the application of a contact adhesive. A polyethylene film is placed on the cemented side of the tread to prevent contamination.

The cushion is supplied to the factory in either calendared sheets or as strip stock to be used in an extruder. The calendared cushion is supplied in different widths and thickness. As the first step of the building processes, the casing is placed on a builder machine equipped with an expandable hub, like that on the buffer. The hub is expanded and the leading edge of the tread is cut to provide a uniform uncontaminated surface.