- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

RIGHT

-

Model Number:

-

RT-406

-

Product name:

-

Digital Paper Cardboard Mullen Burst Tester For Bursting Strength

-

Capacity choice:

-

50kg or 100kg

-

Resolution:

-

0.01 kg/cm2

-

Hydraulic speed:

-

170±20cc/min

-

Hydraulic oil:

-

glycerin 85%,distilled water15%

-

Display:

-

LCD monitor

-

Unit of force:

-

kg/cm2, KPa, or self-set

-

Clamping pressure:

-

5kg/cm2, adjustable

-

printer:

-

micro-printer

-

Air-pressure:

-

min 6kg/cm2 (customer-owned)

Quick Details

-

Warranty:

-

24 months

-

Power:

-

Electronic

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

RIGHT

-

Model Number:

-

RT-406

-

Product name:

-

Digital Paper Cardboard Mullen Burst Tester For Bursting Strength

-

Capacity choice:

-

50kg or 100kg

-

Resolution:

-

0.01 kg/cm2

-

Hydraulic speed:

-

170±20cc/min

-

Hydraulic oil:

-

glycerin 85%,distilled water15%

-

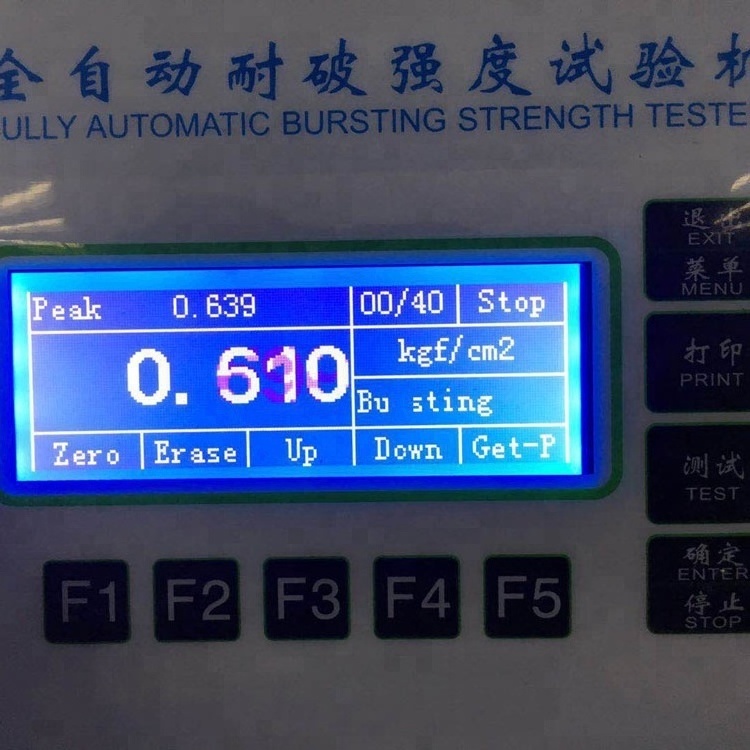

Display:

-

LCD monitor

-

Unit of force:

-

kg/cm2, KPa, or self-set

-

Clamping pressure:

-

5kg/cm2, adjustable

-

printer:

-

micro-printer

-

Air-pressure:

-

min 6kg/cm2 (customer-owned)

Products Description

RT-406 Paper Rupture Strength Testing Machine

RT-406 Automatic Rupture Strength Tester is applied to test anti-rupture strength for raw paper, corrugated cardboard, leather, cloth and synthetic leather. This tester is fully automatic-type rupture strength tester, Just put into the testing material, the tester automatically detect, automatic testing, automatic hydraulic recoil and automatic computing, storage testing data and printing. It is an important tester for controlling quality of finished product and quality inspection.

Specification

|

Model

|

RT-406 Automatic Rupture Strength Tester tester

|

|

Capacity choice

|

0~20, 50 kg/cm²can be set

|

|

Resolution

|

0.01 kg/cm²

|

|

Hydraulic speed

|

170±20cc/min

|

|

Hydraulic oil

|

glycerin 85%,distilled water15%

|

|

Display

|

PLC touch screen, can connect computer

|

|

Unit of force

|

kg/cm², KPa, or self-set

|

|

Specific featuretester with micro-printer

|

|

|

Clamping pressure

|

5kg/cm², adjustable

|

|

Air-pressure

|

min 6kg/cm² (customer-owned)

|

|

Volume

|

(W×D×H)56×47×55 cm

|

|

Weight

|

113kg

|

|

Power

|

AC220V,3A

|

Applicable Industry

Corresponding Standard:

Automatic Rupture Strength Tester operative standardI:ISO-2759,GB-6545,JIS-P8112,L1018,

ASTM-D2210,TAPPI-T403

Applicable Industry:

Automatic Rupture Strength Tester tester applied to test the anti-breaking strength of boxes for packaging,

which of electronics, electrical appliances, wires, hardware, bicycles, handbags, food, footwear, clothing, furniture.etc.

Product Feature

1. It is applicable to test bursting strength for paperboard.

2. Advanced micro computer controller and digital processor ensure result precise.

3. Printer facility and fully detailed test reports.

4. Results of the tests are stored for viewing or for printing out as required.

5. User-friendly menu interface.

6. Power protection ensure automatic record when power cut off.

Installation Instructions

A.

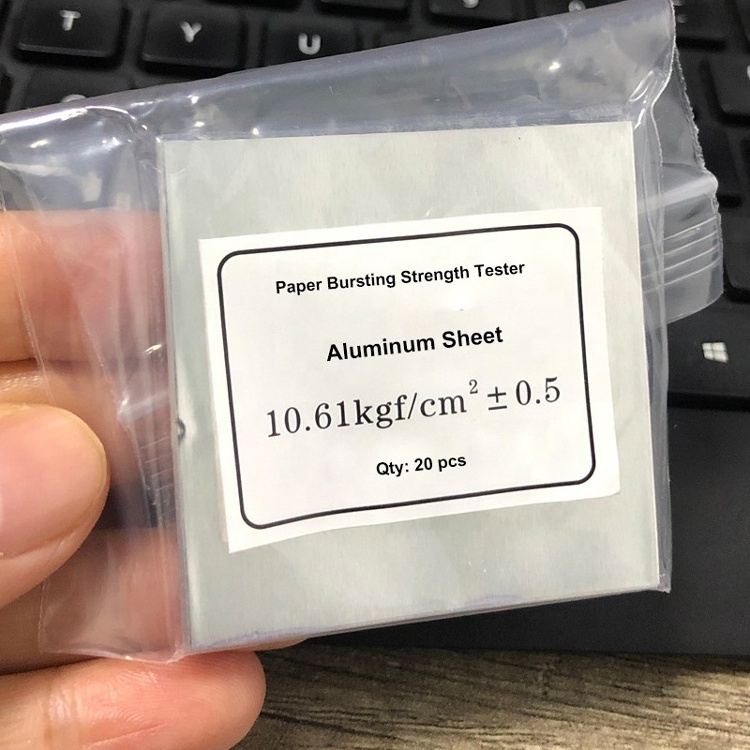

Film resistance has a direct impact on the final test results, and the film resistance of the instrument should be regularly checked according to the requirements of this manual.

B.

The film resistance check according to the following steps:

1. Take the upper and lower clip rings, and place the height gauge randomly equipped with the clip rings;

2 point operation, so that the film raised to just touch the height gauge;

3. Read the values on the display.

C.

Replace the new film, as follows:

1. Lock the oil cup bolt;

2. Under the film verification window, click "Test" cylinder to automatically press down and press down the press plate. When the lower press plate is rotated and loosened, press the "test" button, the cylinder will automatically return and proceed to the next step, and press down the tension of the rubber film.

3 Loosen the pressure ring with a wrench; Note: When releasing the pressure ring, the upper pressure plate must press the lower pressure plate.

4. Remove the lower pressure plate and the old film.

5. Place the new film on the round table at the top of the test cylinder block, note that the plane should be downward.

6. Assemble in reverse order and place inner cover.

7. Place the outer cover and tighten it, align the upper pressure plate with the screw, and insert the rotary table into the connecting hole.

8. Tighten the turntable so that the top force of the rubber film is under pressure, and then tighten the outer cover, and repeated 5-6 times, until the wrench can not be rotated, so as to prevent oil leakage from too loose installation.

9. Loosen oil cup bolts.

10. Press the rubber film a few times, the glycerin in the cup if floating, indicating that the oil circuit is smooth.

11. Hold the rubber film for about 10 seconds, let the glycerin flow down and replenish, then tighten the bolt.

12. Re-check the resistance of the film.

Customer Comments

Recommend Products

Hot Searches