- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380v/3p

-

Rated Power:

-

20kw

-

Dimension(L*W*H):

-

3*4m

-

Weight (KG):

-

300 KG

-

Product name:

-

CNC Plasma metal cutter

-

Effective Cutting Width:

-

Track Gauge-1500

-

Plasma Cutting Thickness:

-

3-50mm

-

Cutting Torch Lifting Stroke:

-

60mm

-

Machine Running Speed:

-

50-45000mm/min

-

Velocity Error:

-

≤±5%

-

Vertical Line Accuracy:

-

±0.2mm/10m

-

Linear Repetition Accuracy:

-

±0.4mm/10m

-

Positioning Precision:

-

0.1mm

-

Keyword:

-

table cnc plasma cutting machine

Quick Details

-

Place of Origin:

-

Hubei, China

-

Brand Name:

-

Fiber Laser

-

Marketing Type:

-

Hot Product 2021

-

Voltage:

-

380v/3p

-

Rated Power:

-

20kw

-

Dimension(L*W*H):

-

3*4m

-

Weight (KG):

-

300 KG

-

Product name:

-

CNC Plasma metal cutter

-

Effective Cutting Width:

-

Track Gauge-1500

-

Plasma Cutting Thickness:

-

3-50mm

-

Cutting Torch Lifting Stroke:

-

60mm

-

Machine Running Speed:

-

50-45000mm/min

-

Velocity Error:

-

≤±5%

-

Vertical Line Accuracy:

-

±0.2mm/10m

-

Linear Repetition Accuracy:

-

±0.4mm/10m

-

Positioning Precision:

-

0.1mm

-

Keyword:

-

table cnc plasma cutting machine

Perfect Laser-Automatic Calculation Manual Adjustment Automatic Aalvanized Sheet Industrial Table CNC Plasma Cutting Machine

(Model:PE-CUT-A3)

Contact:Claire Wechat/Whatsapp:+8613627237391 Email:sales33(@)perfectlaser.net

Product Description

Automatic Industrial Desktop cnc plasma cutter PE-CUT-A3 adopts heavy machine tool design. It combined with the high speed cnc plasma cutting and the need for plate processing heavy machine stability. Berefore, this best plasma cutter has good rigidity and long stability as well as a significant advantage in thick steel and aluminum materials in cutting 1-20 mm. At the same time, the plasma cutters for sale is equipped with automatic height adjustment system, it can improve work efficiency and save costs.

Main Features

1. Maximum working area of the cnc plasma cutting machine:1.5*3M;Cutting thickness: 5MM; The maximum cutting thickness: 25MM

2.Processing materials of the cnc plasma cutting machine: cold binding plate, stainless steel plate, galvanized sheet, copper plate, aluminum plate and other metal sheet.

3.This cnc plasma cutter is specially developed for the cutting of sheet metal, and the cutting accuracy and effect have reached the requirements of the industry.

4. This cnc plasma cutter can support AI, DXF, PLT, and other graphics data format;this plasma cutting table is also able to accept MasterCam, Type3, Wen Tai software generated international standard G code.

5. The CNC system of the best plasma cutter uses the current advanced integrated module control mode, which ensure that the equipment in high precision, high stability in the state of reliable operation

6. With automatic calculation of cutting slot compensation, the plasma cutting table can greatly reduce the production time processing of data and can ensure sound processing of graphic size.

7. The cnc plasma cutter with automatically optimize the order of processing, but also manual adjustment, reduce processing time, improve processing efficiency.

8. The breakpoint, power failure processing, the processing process of the cnc plasma cutting machine can track along, back, flexible handling process encountered arcing, power failure.

9.After the system transfers graphics and image data, the cnc plasma cutter can edit and edit such as zoom, rotate, align, copy, combine, split, smooth, merge, etc.

10.This cnc plasma cutting machine can increase the output and programming operation of the front and back table as well as the cutting function of the machining area and the border.

11.Automatic arc, automatic adjusting system, cutting steel plate with rugged automatic adjustment function, to ensure uniform distance between the cutting torch and the plate cutting, thus the cnc plasma cutter can ensure the cutting quality.

2.Processing materials of the cnc plasma cutting machine: cold binding plate, stainless steel plate, galvanized sheet, copper plate, aluminum plate and other metal sheet.

3.This cnc plasma cutter is specially developed for the cutting of sheet metal, and the cutting accuracy and effect have reached the requirements of the industry.

4. This cnc plasma cutter can support AI, DXF, PLT, and other graphics data format;this plasma cutting table is also able to accept MasterCam, Type3, Wen Tai software generated international standard G code.

5. The CNC system of the best plasma cutter uses the current advanced integrated module control mode, which ensure that the equipment in high precision, high stability in the state of reliable operation

6. With automatic calculation of cutting slot compensation, the plasma cutting table can greatly reduce the production time processing of data and can ensure sound processing of graphic size.

7. The cnc plasma cutter with automatically optimize the order of processing, but also manual adjustment, reduce processing time, improve processing efficiency.

8. The breakpoint, power failure processing, the processing process of the cnc plasma cutting machine can track along, back, flexible handling process encountered arcing, power failure.

9.After the system transfers graphics and image data, the cnc plasma cutter can edit and edit such as zoom, rotate, align, copy, combine, split, smooth, merge, etc.

10.This cnc plasma cutting machine can increase the output and programming operation of the front and back table as well as the cutting function of the machining area and the border.

11.Automatic arc, automatic adjusting system, cutting steel plate with rugged automatic adjustment function, to ensure uniform distance between the cutting torch and the plate cutting, thus the cnc plasma cutter can ensure the cutting quality.

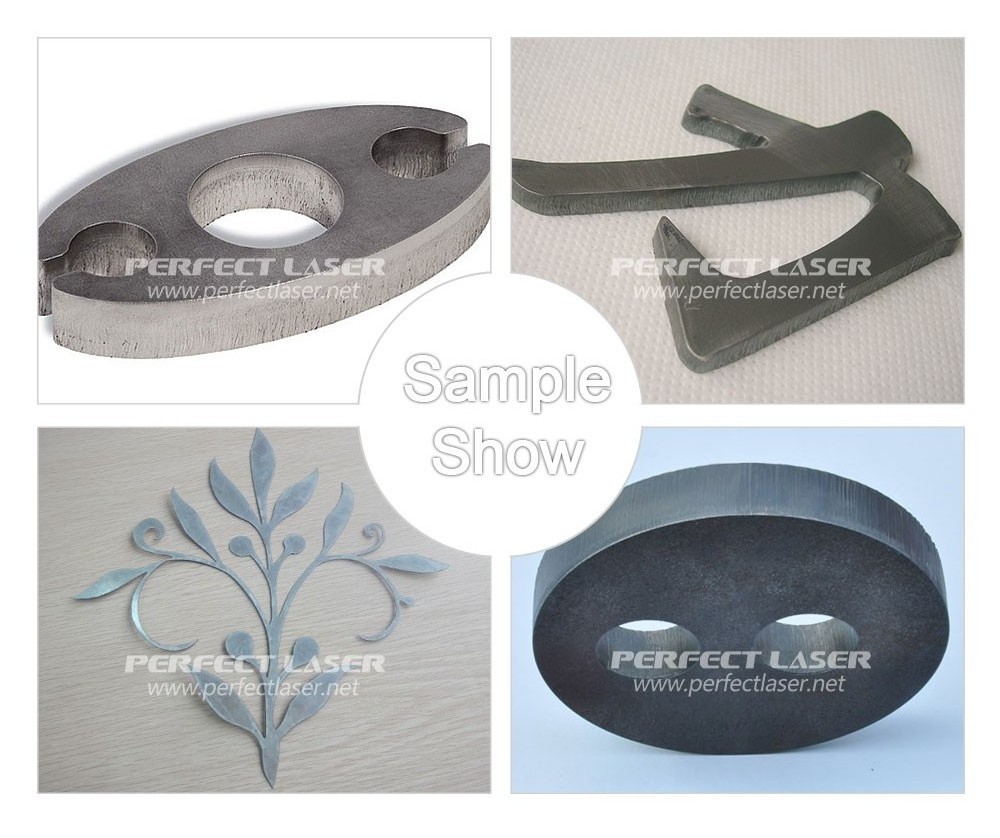

Application & Sample

Application Material

This kind of cnc plasma cutting machine is widely applied in special-shaped carbon steel, manganese steel, stainless steel, non-ferrous metals (stainless steel, aluminum, copper, titanium, nickel) and other metal materials of large, medium and small plates.

Application field

This kind of cnc plasma cutting machine is widely applied in shipbuilding industry, heavy machinery, petrochemical, power equipment, boiler manufacturing, machinery manufacturing, aerospace, vehicle manufacturing.

This kind of cnc plasma cutting machine is widely applied in special-shaped carbon steel, manganese steel, stainless steel, non-ferrous metals (stainless steel, aluminum, copper, titanium, nickel) and other metal materials of large, medium and small plates.

Application field

This kind of cnc plasma cutting machine is widely applied in shipbuilding industry, heavy machinery, petrochemical, power equipment, boiler manufacturing, machinery manufacturing, aerospace, vehicle manufacturing.

Detailed Images

Technical Data

|

Model

|

PE-CUT-A3

|

|

|

||

|

Effective Cutting Width(㎜)

|

Track Gauge-1500

|

|

|

||

|

Effective Cutting Length(㎜)

|

Gauge Length-3000

|

|

|

||

|

Plasma Cutting Thickness(mm)

|

1-25mm

|

|

|

||

|

Cutting Torch Lifting Stroke(㎜)

|

60mm

|

|

|

||

|

Machine Running Speed(mm/min)

|

50-45000mm/min

|

|

|

||

|

Velocity Error(%)

|

≤±5%

|

|

|

||

|

Automatic Height Adjustment Accuracy(MM)

|

≤±1.0mm

|

|

|

||

|

Weight

|

550KG

|

|

|

||

|

Vertical Line Accuracy

|

±0.2mm/10m

|

|

|

||

|

Linear Repetition Accuracy

|

±0.4mm/10m

|

|

|

||

|

Installation Accuracy of Rail

|

Rail Side Straightness:0.5mm/10000mm

The parallel degree between the rail and the horizontal plane of the guide rail:±0.5mm/10000mm |

|

|

||

|

Positioning Precision

|

0.1㎜

|

A)Equipment positioning accuracy and repeatability: conform to JB/T5102-1999 standard

B)Cutting dimension accuracy, section quality: conform to JB/T10045.3-1999 standard |

|

||

|

Straightness

|

0.2㎜

|

|

|

||

|

Roundness

|

0.2㎜

|

|

|

||

|

Diagonal Difference

|

0.3㎜

|

|

|

||

|

Repeated Positioning Accuracy

|

0.5㎜

|

|

|

||

|

Machine Marking Accuracy

|

≤0.5m

|

|

|

||

|

Cutting Surface Quality(Roughnes) (σ=25)

|

|

RZ(um)=70+1.2a

Visual Measurement: roughness12.5 |

|

||

Packing & Delivery

Packing Details : 3 layers package for machine:

1.For the outside, we adopt wood craft case.

2.In the middle, the machine is covered by foam, to protect the machine from shaking.

3.For the inside layer, the machine is covered by thickening plastic bag for waterproof.

Delivery Port : Shanghai / Guangzhou / Shenzhen

Our Company

Contact Us

Perfect Laser Co., Ltd (China)

Contact: Claire / Sales Manager

MP : 0086-13627237391

Tel: 0086-27-86791986

Fax: 0086-27-86775865

E-mail: sales33(@)perfectlaser.net

Whatsapp: 0086-13627237391

Skype: perfectlaser033

Wechat: 0086-13627237391

QQ: 2022218229

Add: No.13 YangQiaohu Road,East Lake High-tech Development Zone,Optics Valley, Hubei, China (430200)

Contact: Claire / Sales Manager

MP : 0086-13627237391

Tel: 0086-27-86791986

Fax: 0086-27-86775865

E-mail: sales33(@)perfectlaser.net

Whatsapp: 0086-13627237391

Skype: perfectlaser033

Wechat: 0086-13627237391

QQ: 2022218229

Add: No.13 YangQiaohu Road,East Lake High-tech Development Zone,Optics Valley, Hubei, China (430200)

Hot Searches