- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

ZW-0.4-10-16, According to customer's requirements

-

Voltage:

-

380V/60HZ

-

Dimension(L*W*H):

-

2800*2200*1600mm

-

Weight:

-

1000KG

-

Marketing Type:

-

Hot Product 2023

-

Core Components:

-

Crankshafts, Bearings, Connecting Rods, Crossheads, Pulleys, Couplings, Valves

-

Gas Type:

-

Petroleum

-

Product name:

-

LNG compressor

-

Cooling method:

-

Water Cooled

-

Keywords:

-

Reciprocating Natural Gas Compressor

-

Pressure:

-

Customized

-

Usage:

-

for liquid transportation and gas recovery

-

Power:

-

5.5KW

-

Color:

-

Customized Color

-

Capacity:

-

60~1620Nm3/h

-

Driven method:

-

Belt Drven

-

Brand:

-

HUAYAN

Quick Details

-

Applicable Industries:

-

Metallurgy, Electronic power, Food Packaging, Chemical Industry

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

HUAYAN

-

Model Number:

-

ZW-0.4-10-16, According to customer's requirements

-

Voltage:

-

380V/60HZ

-

Dimension(L*W*H):

-

2800*2200*1600mm

-

Weight:

-

1000KG

-

Marketing Type:

-

Hot Product 2023

-

Core Components:

-

Crankshafts, Bearings, Connecting Rods, Crossheads, Pulleys, Couplings, Valves

-

Gas Type:

-

Petroleum

-

Product name:

-

LNG compressor

-

Cooling method:

-

Water Cooled

-

Keywords:

-

Reciprocating Natural Gas Compressor

-

Pressure:

-

Customized

-

Usage:

-

for liquid transportation and gas recovery

-

Power:

-

5.5KW

-

Color:

-

Customized Color

-

Capacity:

-

60~1620Nm3/h

-

Driven method:

-

Belt Drven

-

Brand:

-

HUAYAN

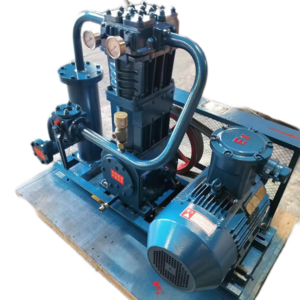

China Hot Selling Cng Natural Gas Filling Stations Piston Compressors

Our company specialize in making various kinds of compressors, such as:Diaphragm compressor,Piston compressor, Air compressors,Nitrogen generator,Oxygen generator ,Gas cylinder,etc. All products can be customized according to your parameters and other requirements.

This series of oil-free compressor is one of the first products produced by our factory in China. The product has the characteristics of low speed, high component strength, stable operation, long service life and convenient maintenance. This series compressor is in the form of unit. It integrates compressor, gas-liquid separator, filter, two position four-way valve, safety valve, check valve, explosion-proof motor and chassis. The utility model has the advantages of small volume, light weight, low noise, good sealing performance, easy installation, simple operation, etc.

Main components:

1. Motion system: crankshaft, piston connecting rod assembly, coupling, etc.

2. Air distribution system: valve plate, valve spring, etc.

3. Sealing system: piston ring, oil seal, gasket, packing, etc.

4. Body system: crankcase, cylinder block, cylinder liner, cover plate, etc.

5. Lubrication system: lubricating oil pump, oil filter, pressure regulating valve, etc.;

6. Safety and energy regulation systems: safety valves, energy regulation devices, etc.

Working principle of piston compressor

When the crankshaft of the piston compressor rotates, the piston will reciprocate through the transmission of the connecting rod,and the working volume formed by the inner wall of the cylinder, the cylinder head and the top surface of the piston will periodically change. When the piston of a piston compressor starts to move from the cylinder head, the working volume in the cylinder gradually increases. At this time, the gas flows along the intake pipe and pushes the intake valve to enter the cylinder until the working volume reaches the maximum. , The intake valve is closed; when the piston of the piston compressor moves in the reverse direction, the working volume in the cylinder is reduced, and the gas pressure is increased. When the pressure in the cylinder reaches and is slightly higher than the exhaust pressure, the exhaust valve opens and the gas is discharged from the cylinder , Until the piston moves to the limit position, the exhaust valve is closed. When the piston of the piston compressor moves in the reverse direction again, the above process repeats. In short, the crankshaft of a piston compressor rotates once, the piston reciprocates once, and the process of air intake, compression, and exhaust is realized in the cylinder, which completes a work cycle.

Advantages of piston compressor

1. The applicable pressure range of the piston compressor is wide, and the required pressure can be reached regardless of the flow rate;

2. The piston compressor has high thermal efficiency and low unit power consumption;

3. Strong adaptability, that is, a wide exhaust range, and is not affected by the pressure level, and can adapt to a wider

pressure range and cooling capacity requirements;

4. Piston compressors have low requirements for materials, and use common steel materials, which is easier to process and lower in cost;

5. The piston compressor is relatively mature in technology, and has accumulated rich experience in production and use;

6. The device system of the piston compressor is relatively simple.

Note: In the unloading process, the compressor pressurizes the gas from the storage tank and then presses it into the tank car through the gas-phase pipeline, and presses the liquid from the tank car to the storage tank through the gas-phase differential pressure to complete the unloading process. When the gas phase is pressurized, the temperature of the gas phase will rise. At this time, forced cooling is not necessary, because if the gas phase is compressed and then cooled, it is easy to liquefy, and it is difficult to establish the pressure difference of the gas phase, which is not conducive to the replacement of the gas phase and the liquid phase. In short, it will cause the prolongation of the unloading process. If it is necessary to recover the residual gas, the cooler can be selected to forcibly cool the gas phase during the recovery operation, so as to recover the residual gas as soon as possible.The loading process is opposite to the unloading process.

Chemical Process Compressor Description

Chemical process compressors refer to process reciprocating piston compressors used to compress various single or mixed media gases in petroleum and chemical processes, as well as chemical exhaust gas recycling systems. Its main function is to transport the medium gas in the reaction device and provide the required pressure to the reaction device. Features

2. Air distribution system: valve plate, valve spring, etc.

3. Sealing system: piston ring, oil seal, gasket, packing, etc.

4. Body system: crankcase, cylinder block, cylinder liner, cover plate, etc.

5. Lubrication system: lubricating oil pump, oil filter, pressure regulating valve, etc.;

6. Safety and energy regulation systems: safety valves, energy regulation devices, etc.

Working principle of piston compressor

When the crankshaft of the piston compressor rotates, the piston will reciprocate through the transmission of the connecting rod,and the working volume formed by the inner wall of the cylinder, the cylinder head and the top surface of the piston will periodically change. When the piston of a piston compressor starts to move from the cylinder head, the working volume in the cylinder gradually increases. At this time, the gas flows along the intake pipe and pushes the intake valve to enter the cylinder until the working volume reaches the maximum. , The intake valve is closed; when the piston of the piston compressor moves in the reverse direction, the working volume in the cylinder is reduced, and the gas pressure is increased. When the pressure in the cylinder reaches and is slightly higher than the exhaust pressure, the exhaust valve opens and the gas is discharged from the cylinder , Until the piston moves to the limit position, the exhaust valve is closed. When the piston of the piston compressor moves in the reverse direction again, the above process repeats. In short, the crankshaft of a piston compressor rotates once, the piston reciprocates once, and the process of air intake, compression, and exhaust is realized in the cylinder, which completes a work cycle.

Advantages of piston compressor

1. The applicable pressure range of the piston compressor is wide, and the required pressure can be reached regardless of the flow rate;

2. The piston compressor has high thermal efficiency and low unit power consumption;

3. Strong adaptability, that is, a wide exhaust range, and is not affected by the pressure level, and can adapt to a wider

pressure range and cooling capacity requirements;

4. Piston compressors have low requirements for materials, and use common steel materials, which is easier to process and lower in cost;

5. The piston compressor is relatively mature in technology, and has accumulated rich experience in production and use;

6. The device system of the piston compressor is relatively simple.

Note: In the unloading process, the compressor pressurizes the gas from the storage tank and then presses it into the tank car through the gas-phase pipeline, and presses the liquid from the tank car to the storage tank through the gas-phase differential pressure to complete the unloading process. When the gas phase is pressurized, the temperature of the gas phase will rise. At this time, forced cooling is not necessary, because if the gas phase is compressed and then cooled, it is easy to liquefy, and it is difficult to establish the pressure difference of the gas phase, which is not conducive to the replacement of the gas phase and the liquid phase. In short, it will cause the prolongation of the unloading process. If it is necessary to recover the residual gas, the cooler can be selected to forcibly cool the gas phase during the recovery operation, so as to recover the residual gas as soon as possible.The loading process is opposite to the unloading process.

Chemical Process Compressor Description

Chemical process compressors refer to process reciprocating piston compressors used to compress various single or mixed media gases in petroleum and chemical processes, as well as chemical exhaust gas recycling systems. Its main function is to transport the medium gas in the reaction device and provide the required pressure to the reaction device. Features

1. Designed for specific process flow.

2. The whole machine is skid-mounted and advanced in structure.

3. The compressor types are: Z type, D type, M type.

4. The middle body of the slideway and the cylinder can be designed in different structural forms according to the process requirements.

4. The middle body of the slideway and the cylinder can be designed in different structural forms according to the process requirements.

|

S/C

|

Model Number

|

Motor Power (KW)

|

Size (mm)

|

Loading and unloading (t/h)

|

|

1

|

ZW-0.4/16-24

|

7.5

|

1000×700×1000

|

~11

|

|

2

|

ZW-0.6/16-24

|

11

|

1100×700×1000

|

~17.5

|

|

3

|

ZW-0.8/16-24

|

15

|

1100×700×1000

|

~23

|

|

4

|

ZW-1.0/16-24

|

22

|

1100×800×1050

|

~29

|

|

5

|

ZW-1.1/16-24

|

22

|

1100×800×1050

|

~31

|

|

6

|

ZW-1.5/16-24

|

30

|

1400×900×1180

|

~43

|

|

7

|

ZW-2.0/16-24

|

37

|

1400×900×1180

|

~58

|

|

8

|

ZW-2.5/16-24

|

45

|

1400×900×1180

|

~73

|

Inlet pressure: ≤1.6MPa

Exhaust pressure: ≤2.4MPa

Differential pressure: 0.8MPa

Instant pressure ratio: ≤4

Cooling method: air cooling

The unloading volume is calculated according to the inlet pressure of 1.6MPa, the discharge pressure of 2.4MPa, the inlet temperature of 40℃, and the liquid ammonia density of 729kg/m3. When the working conditions change, the unloading volume will change accordingly, which is for reference only.

Product Description

|

No.

|

Name

|

Unit

|

Technical Information

|

|

1

|

Model and name

|

|

ZW-0.4/10-16 Oil-free LPG unloading compressor

|

|

2

|

Type

|

|

Vertical, air-cooled, two-row twin-cylinder one-stage compression,

Oil-free, reciprocating piston unit |

|

3

|

Medium

|

|

LPG

|

|

4

|

Flow rate (ntake state)

|

m3/min

|

0.4

|

|

5

|

Suction pressure (gauge pressure)

|

MPa

|

1.0

|

|

6

|

Exhaust pressure (gauge pressure))

|

MPa

|

1.6

|

|

7

|

Suction temperature

|

℃

|

≤40

|

|

8

|

Exhaust temperature

|

℃

|

≤110

|

|

9

|

Cooling method

|

|

Air cooling

|

|

10

|

Lubrication method

|

|

Splash lubrication of crank connecting rod kinematics

Oil-free for Cylinder Filling |

|

11

|

Compressor motor drive mode

|

|

Belt drive

|

|

12

|

Compressor speed

|

r/min

|

550

|

|

13

|

Compressor noise

|

db

|

≤85

|

|

14

|

Size

|

mm

|

1000×780×1050(L、W、H)

|

|

15

|

Life

|

|

25 Year

|

|

16

|

Motor Model

|

|

YB132S-4 three-phase asynchronous explosion-proof motor

|

|

17

|

Rated powe

|

kW

|

5.5

|

|

18

|

Rated voltage

|

V

|

380

|

|

19

|

Explosion-proof grade

|

|

dIIBT4

|

|

20

|

Protection class

|

|

IP55

|

|

21

|

Insulation class

|

|

F

|

Specification

|

Model

|

Volume flow(Nm3/h)

|

Suction pressure(Mpa)

|

Exhaust pressure (Mpa)

|

Motor power(kw)

|

Dimension (mm)

|

|

ZW-0.4/ 2-250

|

60

|

0.2

|

25

|

18.5

|

2800*2200*1600

|

|

ZW-0.81/ (1~3)-25

|

120

|

0.1~0.3

|

2.5

|

22

|

1000*580*870

|

|

DW-5.8/0.5-5

|

400~500

|

0.05

|

0.5

|

37

|

2000*1600*1200

|

|

DW-10/2

|

510

|

Atmospheric pressure

|

0.2

|

37

|

2000*1600*1200

|

|

DW-6.0/5

|

300

|

Atmospheric pressure

|

0.5

|

37

|

2000*1600*1200

|

|

DW-0.21/(20~30)-250

|

270

|

2~3

|

25

|

45

|

3200*2200*1600

|

|

ZW-0.16/60-250

|

480

|

6

|

25

|

45

|

3000*2200*1600

|

|

ZW-0.46 /(5~10)-250

|

200

|

0.5~1.0

|

25

|

45

|

3000*2200*1600

|

|

DW-1.34/2-250

|

208

|

0.2

|

25

|

55

|

3400*2200*1600

|

|

DW-0.6/24-85

|

720

|

2.4

|

8.5

|

55

|

2200*1600*1200

|

|

ZW-2.9/14.2-20

|

220

|

1.42

|

2

|

55

|

2200*1600*1200

|

|

VW-2.0/(2~4)-25

|

410

|

0.2~0.4

|

2.5

|

55

|

3400*2200*1600

|

|

DW-0.85/(3~4)-250

|

180

|

0.3~0.4

|

25

|

55

|

2400*1800*1500

|

|

DW-25-(0.2~0.3)-1.5

|

1620

|

0.02~0.03

|

0.15

|

75

|

2400*1800*1500

|

|

VW-8.0/0.3-25

|

540

|

0.03

|

2.5

|

90

|

2400*1800*1500

|

|

DW-6.8/0.05-40

|

200~400

|

0.005

|

4

|

90

|

2400*1800*1500

|

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Hot Searches