- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

+-0.1%

-

Driven Type:

-

servo motor

-

Voltage:

-

can be customized

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

BRIGHTWIN

-

Dimension(L*W*H):

-

1500*800*1800MM

-

Weight:

-

400 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

type:

-

general

-

name:

-

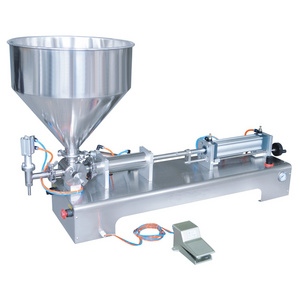

automatic efficient peanut butter filling machine

-

usage:

-

automatic efficient peanut butter filling machine

-

material:

-

stainless steel 304/316

-

design:

-

according to products and sample bottles etc

-

only quick wear part:

-

seal ring

-

engineer and technicians:

-

with over 15 years experience

-

measuring:

-

piston pump

-

Keywords:

-

automatic efficient peanut butter filling machine

Quick Details

-

Machinery Capacity:

-

Other, 6000BPH, 2000BPH

-

Packaging Material:

-

Glass, Plastic

-

Filling Material:

-

Other, Milk, Water, Oil, Juice

-

Filling Accuracy:

-

+-0.1%

-

Driven Type:

-

servo motor

-

Voltage:

-

can be customized

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

BRIGHTWIN

-

Dimension(L*W*H):

-

1500*800*1800MM

-

Weight:

-

400 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

type:

-

general

-

name:

-

automatic efficient peanut butter filling machine

-

usage:

-

automatic efficient peanut butter filling machine

-

material:

-

stainless steel 304/316

-

design:

-

according to products and sample bottles etc

-

only quick wear part:

-

seal ring

-

engineer and technicians:

-

with over 15 years experience

-

measuring:

-

piston pump

-

Keywords:

-

automatic efficient peanut butter filling machine

automatic efficient

peanut butter

filling machine for quick operations

Overview

This machine is used to fill various liquid, viscous liquid or thick liquid products, like cooking oil, lube oil, beverage, juice, sauce, paste, cream, honey, shampoo, detergent, pesticides, and Liquid fertilizer etc as long as it can flow. It adopts piston pump filling with servo motor driven which is more accurate and easy to adjust the volume. With rotary valve for thick or viscous liquid products and non-rotary valve for liquid products.

It can be connected with other automatic machines to compose an automatic filling and packaging line, as:

Main features:

1. With PLC + human-computer touch screen control system. The PLC can save the parameters for later use. Operators do not need too much complicated operation.

2. Adopts Mitsubishi servo motor to drive piston pumps, with high speed and high filling accuracy; its also easier for adjusting volumes, only need to input the volume you want to fill from touch screen.

3. The filling nozzles can be with the function of anti-drip, anti-drawing, diving bottom up filling & bubble-kill etc according to the features of different products.

4. For hot filling, we make double jacket tank, which can be heated to keep temperature of products inside. Also with a mixer inside to stir it even.

5. There is a level controller in tank to control the pump to transfer product to the machine tank or stop transferring automatically.

2. Adopts Mitsubishi servo motor to drive piston pumps, with high speed and high filling accuracy; its also easier for adjusting volumes, only need to input the volume you want to fill from touch screen.

3. The filling nozzles can be with the function of anti-drip, anti-drawing, diving bottom up filling & bubble-kill etc according to the features of different products.

4. For hot filling, we make double jacket tank, which can be heated to keep temperature of products inside. Also with a mixer inside to stir it even.

5. There is a level controller in tank to control the pump to transfer product to the machine tank or stop transferring automatically.

Technical Parameters

|

Filling nozzles' number

|

1

|

2

|

4

|

6

|

........

|

20

|

|||||

|

Capacity

(For 1L bottles)

|

6-8bpm

|

12-16bpm

|

24-32bpm

|

36-48bpm

|

........

|

120-160bpm

|

|||||

|

Filling volume range

|

10-100ml, 100ml-1L, 1L-5L......(can be customized)

|

|

|

|

|

|

|||||

|

Voltage

|

AC220/380V 50/60HZ (Can be customized)

|

|

|

|

|

|

|||||

Our videos

Our service

Pre-Sales Service

* Inquiry and consulting support.

* Machine testing support.

* View our Factory.

* Machine testing support.

* View our Factory.

After-Sales Service

* Training how to install the machine, training how to use the machine.

* Engineers available to service machinery overseas.

* Engineers available to service machinery overseas.

* Online technical support.

Hot Searches