- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

FE-088

-

Specification:

-

16mm

-

Length:

-

100/200m/Roll

-

Thickness:

-

2.0mm~117.6mm

-

Standard:

-

ISO4427, EN, DIN, AS, ASTM

-

Product name:

-

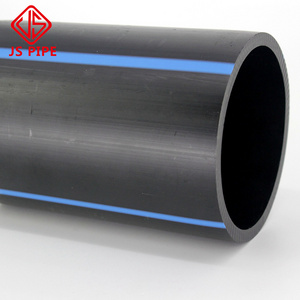

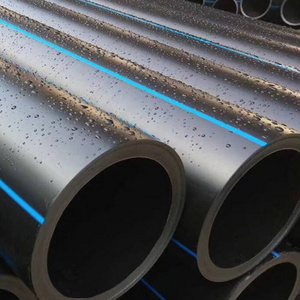

HDPE drip irrigation pipe

-

Color:

-

Black or Customized

-

Raw material:

-

PE80, PE100

-

Working Pressure:

-

0.4Mpa-3.0Mpa

-

Pipe Length:

-

100/200m/Roll

-

MOQ:

-

1000 Meters

-

Working Temperature:

-

- 40℃ to 60℃

-

Application:

-

water supply and drain, ,mining,drainage,dredging,gas,oil

-

Lifespan:

-

60 years for underground use

-

OEM,ODM:

-

Accept

Quick Details

-

Processing Service:

-

Moulding, Cutting

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

YiFang

-

Model Number:

-

FE-088

-

Specification:

-

16mm

-

Length:

-

100/200m/Roll

-

Thickness:

-

2.0mm~117.6mm

-

Standard:

-

ISO4427, EN, DIN, AS, ASTM

-

Product name:

-

HDPE drip irrigation pipe

-

Color:

-

Black or Customized

-

Raw material:

-

PE80, PE100

-

Working Pressure:

-

0.4Mpa-3.0Mpa

-

Pipe Length:

-

100/200m/Roll

-

MOQ:

-

1000 Meters

-

Working Temperature:

-

- 40℃ to 60℃

-

Application:

-

water supply and drain, ,mining,drainage,dredging,gas,oil

-

Lifespan:

-

60 years for underground use

-

OEM,ODM:

-

Accept

Products Description

|

Product name

|

HDPE drip irrigation pipe

|

|

Color

|

Black or Customized

|

|

Raw material

|

PE80, PE100

|

|

Working Pressure

|

0.4Mpa-3.0Mpa

|

|

Pipe Length

|

100/200m/Roll

|

|

MOQ

|

1000 Meters

|

|

Working Temperature

|

- 40℃ to 60℃

|

|

Application

|

water supply and drain, ,mining,drainage,dredging,gas,oil

|

|

Lifespan

|

60 years for underground use

|

|

OEM,ODM

|

Accept

|

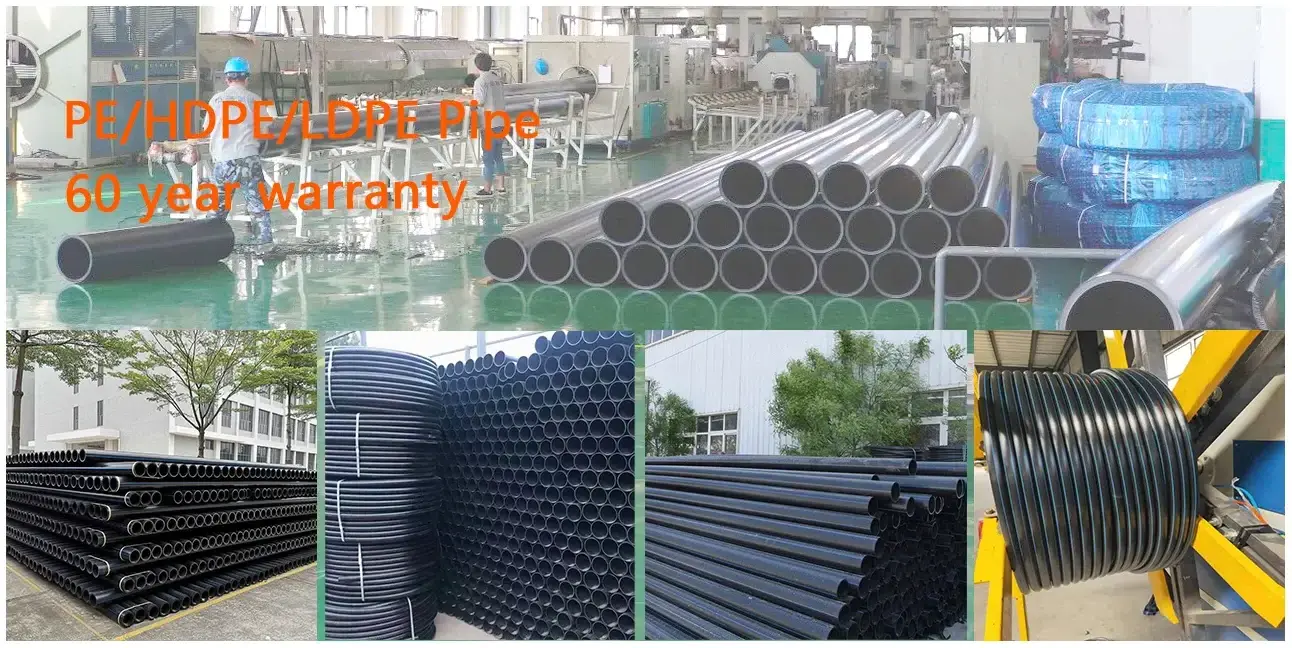

PE water supply pipe

Research & Development

1.Material research

2. Material analysis here.

3. Material preparation

4. Material strength test

5. Material tensile testing

6. Material pressure detection

Manufacturing Technique

Quality

1. Raw material inspection

2.Outer diameter size inspection

3. Wall thickness inspection

4. Length check

Capacity

Detection

1. Ring stiffness/ring compression bending/initial ring stiffness

In this test a pipe of specified length is compressed between two flat discs. The length of pipe taken depends on the nominal diameter of the pipe.

2. Determination of creep properties of thermoplastic pipes

During the test, a constant radial force is applied to the tubular component. Deform the circular cross-section of the pipe by 1.5%.

3. Tensile properties

To characterize this property, test specimens were taken from the pipe wall along the length of the pipe.

4. Strain hardening resistance to slow crack growth

The specimen shape used for this test method is a small dumbbell-shaped specimen with wider ends.

5. Testing plastics for MFR and MVR

The melt index test is a test method used to determine the flow properties of thermoplastic materials.

6. Vicat softening temperature

This test involves the characterization of the thermal properties of thermoplastic pipe materials.

Hot Searches