- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Huahong

-

Dimension(L*W*H):

-

910*750*990

-

Weight:

-

0.8 KG

-

Name:

-

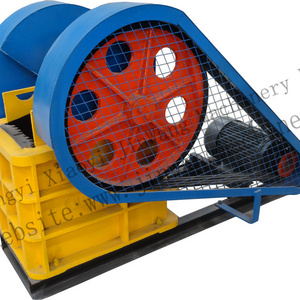

jaw crusher

-

Product name:

-

2017 Newest Technology jaw crusher

-

Color:

-

Customizable

-

Keyword:

-

crusher

-

Test&Installation:

-

Professional Engineer Assigned

-

After sale Service:

-

Life-long Service

-

Installation:

-

Engineer Assigned

-

Max feeding size:

-

1020mm

-

Spare parts supply:

-

Life-long Provide

-

Usage:

-

all kinds of soft or hard stones

Quick Details

-

Application:

-

quarry plant

-

Capacity(t/h):

-

2-8

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Huahong

-

Dimension(L*W*H):

-

910*750*990

-

Weight:

-

0.8 KG

-

Name:

-

jaw crusher

-

Product name:

-

2017 Newest Technology jaw crusher

-

Color:

-

Customizable

-

Keyword:

-

crusher

-

Test&Installation:

-

Professional Engineer Assigned

-

After sale Service:

-

Life-long Service

-

Installation:

-

Engineer Assigned

-

Max feeding size:

-

1020mm

-

Spare parts supply:

-

Life-long Provide

-

Usage:

-

all kinds of soft or hard stones

Product Description

Jaw crusher is easy to install, operate and maintain.It is widely used in fields of mining, metallurgy, construction, smelting, hydropower and chemical industries etc., mainly for the medium-grained crush of veriety of ores, stones, and minerals, etc. It is the corollary equipment of sand/stone making plant and ore beneficiation plant. Also it can produce road cornerstone stones and construction stone aggregate.

Working Principle

The working principle of jaw crusher is very simple. The whole crushing process rely on the relative motion of the two jaw plates. One of the jaw plates is fixed and stay still, the other moves against it by a cam or pitman mechanism.

During this movement, the materials between the two plates would be crushed progressively into small particles: while the plates move against each other, the materials would be crushed, and while plates move apart from each other, the broken materials which are smaller enough would drop through the discharging opening. The movement of the jaw can be quite small, since complete crushing is not performed in one stroke. Due to the simple structure, jaw crusher is easy to maintain and repair. These features promote its popularity to a great extant.

Technical Parameters

| Model |

Max

feed size(mm) |

Adjustable

range (mm) |

Capacity

(t/h) |

Eccentric shaft

rotary speed (r/min) |

Motor

power (kw) |

Total weight

(t) |

Overall dimensions

(L*W*H)(mm) |

| PE-150×250 | 125 | 10-40 | 1-3 | 250 | 5.5 | 0.8 | 720×660×850 |

| PE-200×300 | 180 | 15-50 | 2-6 | 260 | 7.5 | 1.2 | 910×750×990 |

| PE-200×350 | 180 | 18-70 | 3-10 | 260 | 11 | 1.5 | 1000×870×990 |

| PE-250×400 | 210 | 20-60 | 5-20 | 300 | 15 | 2.8 | 1300×1090×1270 |

| PE-400×600 | 340 | 40-100 | 16-60 | 275 | 30 | 7 | 1730×1730×1630 |

| PE-500×750 | 425 | 50-100 | 40-110 | 275 | 55 | 12 | 1980×2080×1870 |

| PE-600×750 | 500 | 150-200 | 80-240 | 275 | 55 | 15.8 | 2070×2000×1920 |

| PE-600×900 | 500 | 65-160 | 50-180 | 250 | 55 | 17 | 2190×2206×2300 |

| PE-750×1060 | 630 | 80-140 | 110-320 | 250 | 90-110 | 29 | 2660×2430×2800 |

| PE-800×1060 | 640 | 160-220 | 130-330 | 250 | 110 | 29.8 | 2710×2430×2800 |

| PE-830×1060 | 650 | 160-220 | 150-336 | 250 | 110 | 30.7 | 2740×2430×2800 |

| PE-870×1060 | 660 | 200-260 | 190-336 | 250 | 110 | 31.5 | 2810×2430×2800 |

| PE-900×1060 | 685 | 230-290 | 230-390 | 250 | 110 | 33 | 2870×2420×2940 |

| PE-900×1200 | 750 | 95-165 | 220-450 | 200 | 110 | 52 | 3380×2870×3330 |

| PE-1000×1200 | 850 | 195-265 | 315-500 | 200 | 110 | 55 | 3480×2876×3330 |

| PE-1200×1500 | 1020 | 150-300 | 400-800 | 180 | 160 | 100.9 | 4200×3300×3500 |

| PEX-150×750 | 120 | 18-48 | 8-25 | 320 | 15 | 3.8 | 1200×1530×1060 |

| PEX-250×750 | 210 | 25-60 | 13-35 | 330 | 30 | 5.5 | 1380×1750×1540 |

| PEX-250×1000 | 210 | 25-60 | 16-52 | 330 | 30 | 7 | 1560×1950×1390 |

| PEX-250×1200 | 210 | 25-60 | 20-61 | 330 | 37 | 9.7 | 2140×1660×1500 |

| PEX-300×1300 | 250 | 20-90 | 16-105 | 300 | 55 | 15.6 |

2720×1950×1600

|

Packing&Delivery

Certifications

Contact Way

Welcome to visit our factory anytime!!!

Hot Searches