- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

After-sales Service Provided:

-

Online support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support

-

Name:

-

concrete block making machine diesel

-

Raw material workshop:

-

300m2

-

Working shed:

-

200m2

-

Working site:

-

1000m2

-

Power distribution:

-

7.5KW

-

Water consumption:

-

3T/DAY

-

Pallets needed:

-

1000pcs

-

Weight:

-

1.2T

-

Staff needed:

-

2-3

-

Certification:

-

ISO9001/CE/SGS

Quick Details

-

Type:

-

Hollow Block Making Machine

-

Brick Raw Material:

-

CONCRETE

-

Production Capacity (Pieces/8 hours):

-

500/Year

-

Place of Origin:

-

Henan, China

-

After-sales Service Provided:

-

Online support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support

-

Name:

-

concrete block making machine diesel

-

Raw material workshop:

-

300m2

-

Working shed:

-

200m2

-

Working site:

-

1000m2

-

Power distribution:

-

7.5KW

-

Water consumption:

-

3T/DAY

-

Pallets needed:

-

1000pcs

-

Weight:

-

1.2T

-

Staff needed:

-

2-3

-

Certification:

-

ISO9001/CE/SGS

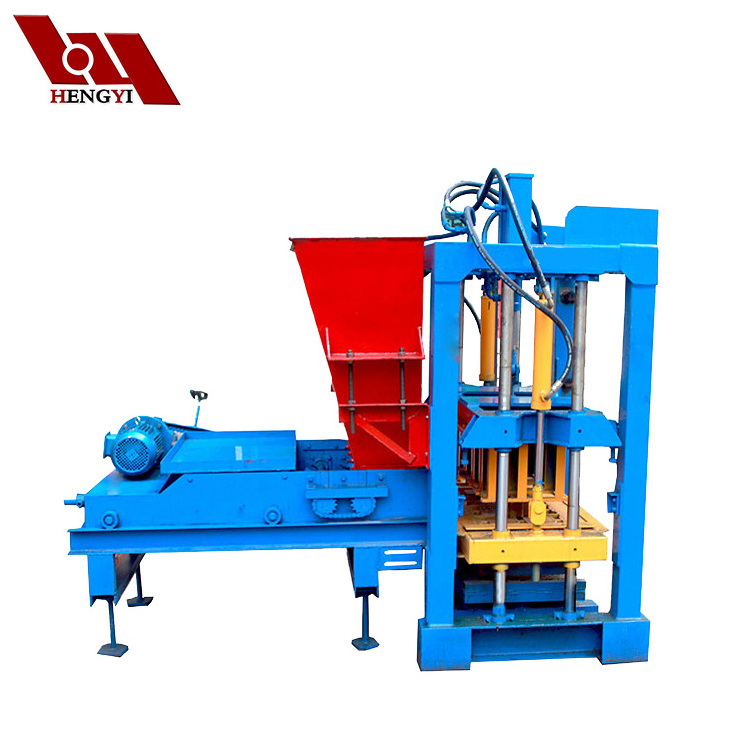

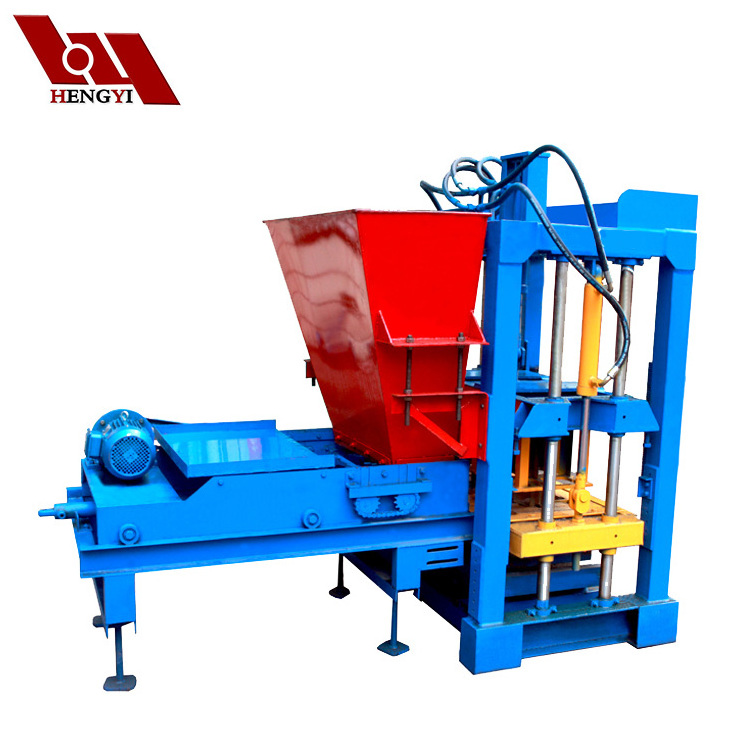

QT4-25BH concrete block making machine diesel

Our concrete block making machine diesel are with simple and compact structure, convenient operation and easy maintenance. It demands litter manpower and investment, but makes high output and quick ROI (return on investment). Especially suitable to produce standard bricks, hollow bricks, pavers, etc. The strength of which is higher than that of clay bricks. Various types of blocks can be produced with different molds. Therefore, It is an ideal choice for enterprises with small investment.

QT4-25BH concrete block making machine diesel

| Model |

QT4-15 |

QT4-22 |

QT4-26 |

QT4-35 |

QT4-25BH |

| Cycle Time(s) | 15s | 22s | 26s | 35s | 25s |

|

PCS/Mould

(240*115*53mm) |

26pcs | 26pcs | 26pcs | 26pcs | 26pcs |

|

PCS/Shift

(240*115*53mm) |

45000pcs | 34000pcs | 28800pcs | 21000pcs | 24960pcs |

| Power(KW) | 23KW | 19.5KW | 14.25KW | 11KW | 7.5KW |

| Dimension(mm) | 3000*2200*2900 | 2950*2150*1600 | 2060*1730*2580 | 1120*1400*1700 | 1400*1050*2350 |

| Pallet Dimension(mm) | 940*580*30mm | 850*550*30mm | 880*550*30mm | 880*480*30mm | 850*550*30mm |

|

Raw material

Workshop(m2) |

450m2 | 400m2 | 400m2 | 300m2 | 300m2 |

| Working shed(m2) | 300m2 | 200m2 | 200m2 | 150m2 | 150m2 |

| Working site(m2) | 3000m2 | 2500m2 | 2500m2 | 1500m2 | 1000m2 |

| Power distribution(KW) | 50KW | 45KW | 42KW | 30KW | 20KW |

| Water consumption | 9t/day | 6t/day | 5t/day | 4t/day | 3t/day |

| Pallets needed (pcs) | 1000pcs | 500-800pcs | 500-800pcs | 500pcs | 500pcs |

| Weight(ton) | 4.3t | 3.0t | 2.4t | 1.1t | 1t |

| Staff needed | 8~10 | 5~8 | 3~5 | 2~3 | 2~3 |

| Warranty(months) | 18 months | 18 months | 18 months | 18 months | 18 months |

|

|

|

Hydraulic Station Hydraulic pressure make blocks more intensy&strong

|

Material Feeder Labor save&High efficiency, feed material evently than manpower |

|

|

|

|

Mould Processed by heat treatment, more strong&durable |

Motor Top brand, copper wire(can be Siemens as per customized ) |

|

Main Specs: |

||||||

|

Environmental protection |

Confirms to the international environmental protection standard |

|||||

|

General power |

15KW |

|||||

|

Average power consumption |

7.5KW/h |

|||||

|

Average water consumption |

4T/day |

|||||

|

Land area |

1000m2 totally |

|||||

|

Technical Specifications: |

||||||

|

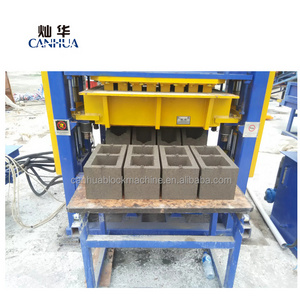

Output capacity per mould |

Standard brick |

240x115x53mm |

26pcs/mould |

|||

|

Porous brick |

240x115x90mm |

9pcs/mould |

||||

|

Hollow brick |

390x190x190mm |

4pcs/mold |

||||

|

Output capacity per hour |

Standard brick |

240x115x53mm |

3120pcs/hour |

|||

|

Porous brick |

240x115x90mm |

2160pcs/hour |

||||

|

Hollow brick |

390x190x190mm |

480pcs/hour |

||||

|

Output per capacity per shift (8hours) |

Standard brick |

240x115x53mm |

24960pcs |

|||

|

Porous brick |

240X115X90mm |

17280pcs |

||||

|

Hollow brick |

390x190x190mm |

3840pcs |

||||

|

Cycle time |

20~30s |

|||||

|

Power |

15kw |

|||||

|

Weight |

1.1T |

|||||

|

Area |

1000m2 |

|||||

|

Workers |

2-3 |

|||||

|

Dimension |

1120*1400*1700mm |

|||||

|

Pallet size |

880*550*30mm |

|||||

|

Suggested pallets numbers |

500pcs |

|||||

|

Equipment list: |

||||||

|

Name of the item |

Quantity |

Remarks |

||||

|

automatic concrete brick making machine |

1 |

|

||||

|

Mixer |

1 |

JW350 |

||||

|

Belt conveyor |

1 |

6m |

||||

|

Free mould |

1 |

|

||||

|

Pallets |

500pcs |

Upon ur request |

||||

|

Block trolley |

1 |

|||||

Production Flow chart:

Associated equipments:

Brick samples

Successful cases & Customer Visiting.

Packaging & Shipping: