- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Living Room

-

Design Style:

-

Contemporary

-

Place of Origin:

-

Jiangsu, China

-

Product name:

-

Engineered Wood Flooring

-

Surface Treatment:

-

Brushed\ Flat\Antique

-

Wood species:

-

Oak Wood Flooring

-

Thickness:

-

10-20mm

-

MOQ:

-

100 Square Meter

-

Installation:

-

Click Lock System

-

Product Shape:

-

Long Board

-

Pressing Process:

-

Cold Pressing

-

Structure:

-

3-layer/Multilayer Supported

-

Grade:

-

ABCD

Quick Details

-

Engineered Wood Flooring Type:

-

Three Layer Engineered Wood Flooring

-

Technics:

-

Brushed

-

Installation Type:

-

Click

-

Application:

-

Living Room

-

Design Style:

-

Contemporary

-

Place of Origin:

-

Jiangsu, China

-

Product name:

-

Engineered Wood Flooring

-

Surface Treatment:

-

Brushed\ Flat\Antique

-

Wood species:

-

Oak Wood Flooring

-

Thickness:

-

10-20mm

-

MOQ:

-

100 Square Meter

-

Installation:

-

Click Lock System

-

Product Shape:

-

Long Board

-

Pressing Process:

-

Cold Pressing

-

Structure:

-

3-layer/Multilayer Supported

-

Grade:

-

ABCD

√Health and Environmental

√Scratch resistant and durable

√Easy to install

♥ Sample Service:

Free sample can be offered freely to the customers, the sample fee will be charged firstly then will be refund in the order the customer released.

♥

One-stop Service:

ZhenRui offers a wide range of services to the clients who import from China. We support our customers in aspects like Design service, Research & Development, Package, Delivery, shipping, After-sales services.

♥

Quality Assurance:

with advanced technology, production lines equipped with imported machines, as well as experienced workers, Yekalon supplies products with trusted quality. We do what you have seen.

Product Description

|

Advantage

|

Anti-slip, Waterproof, Durable,Eco-friendly

|

|

Certificate

|

ISO900,SGS,CE

|

|

Surface Treatment

|

Embossed/Handscraped/Matte/Brushed/White Washed etc

|

|

Technics

|

Engineered Wood Flooring

|

|

Material

|

Oak, Teak, Walnut, Maple, Birch etc.

|

|

Surface treatment

|

Smooth, UV Lacquer(gloss 18-22°),Stained etc

|

Applications

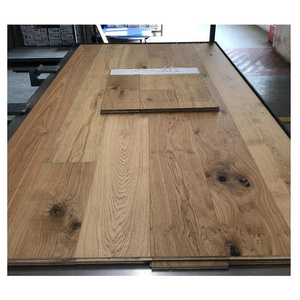

Engineered flooring

, is 100% real wood consists of two or more layers of wood using a cross-directional way to adhered together to form a plank. Typically,engineered wood flooring uses a thin layer of genuine premium hardwood bonded toa core constructed.

This construction counteracts the natural tendency of wood to expand and contract with seasonal changes in temprature and humidity, making engineered products more dimensionally stable.

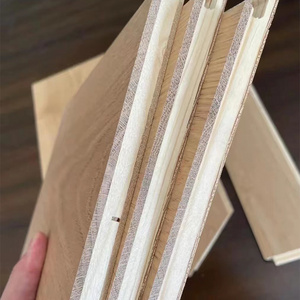

3 Layer engineered wood floor

√ The first layer is a solid wood surface layer, usually 2-6mm thick, showing a natural wood grain and texture.

√

The second layer is the middle layer, using high-density fiberboard (HDF) or compressed wood fiberboard (MDF), with a thickness of about 7-12mm, providing high stability and durability.

√

The third layer is the bottom layer, which can be solid wood or plywood, with a thickness of about 1-4mm, which is used to provide support and balance and enhance the stability of the floor.

Multi-layer engineered wood floor

√

The first layer is also a solid wood surface layer, usually 2-6mm thick, presenting a natural wood grain and texture.

√

The second layer is a core board layer, made of plywood, with a thickness of about 3-12mm, formed by laminating multiple layers of wood to provide stability and durability.

√

The third layer is the bottom layer, similar to the three-layer parquet, which can be solid wood or plywood, with a thickness of about 1-4mm, for support and balance.

Custom Reference

More color choices

More Surface Treatments For Choice

Company Introduction

At present, our company has completed the production of the whole industrial chain of veneer plate processing, substrate

production and finished product customization. Our company has more than 10,000 mu of Eucalyptus planting forest in Guangdong, and has eucalyptus veneer processing plant, which provides strong base material support for the company's base material. Our company purchases oak plates from Europe and North America, processes oak surface plates by itself , and realizes the self-sufficient supply of base materials and surface plates. The quality of floor products is strictly controlled, which greatly meets the supply requirements of customers.

production and finished product customization. Our company has more than 10,000 mu of Eucalyptus planting forest in Guangdong, and has eucalyptus veneer processing plant, which provides strong base material support for the company's base material. Our company purchases oak plates from Europe and North America, processes oak surface plates by itself , and realizes the self-sufficient supply of base materials and surface plates. The quality of floor products is strictly controlled, which greatly meets the supply requirements of customers.

Our Services & Strength

Our company

covers an area of 100 mu

with a planned construction area of

40,000 square meters

. There are

5 production lines

in the base material production workshop, with an annual output of

300,000 cubic meters

of high-quality floor base materials. The base materials include all Eucalyptus base materials, all birch base materials, Eucalyptus birch base materials and other series products. There are 6 frame saws in the sawing surface plate workshop, with an annual output of about

600,000 square meters

of surface plates of various thicknesses and specifications. There are

10 drying kilns

, with a full kiln drying capacity of 800 cubic meters. There are two

750 UV flooring production lines

, with an annual floor processing area of

1.5 million square meters

.

Project Cases

Certificate

Certificate Introduction

Certificate Introduction

Certificate Introduction

FAQ

1、

Q: About the thickness of the solid wood composite layer of the floor, the source of the wood and the processing technology.

A:

our

solid wood composite flooring is made of high-quality raw materials, and the thickness of the solid wood composite layer meets the standard requirements. We use wood sources that are legal and sustainably managed, and undergo a fine processing process to ensure floor quality and durability.

2、

Q:

Whether the floor meets the relevant environmental certification standards

A:

Our parquet meets internationally recognized environmental standards, such as FSC certification and CARB certification. This means that our products come from legal and sustainable forest resources and are environmentally friendly.

3、

Q:

The moisture resistance and humidity resistance of the floor, especially the stability in humid environment.

A:

Our solid wood composite flooring has excellent moisture resistance and humidity resistance. Through reasonable design and treatment process, the floor can remain stable in a humid environment and avoid warping or deformation.

4、

Q:

Installation difficulty and maintenance requirements of floor

A:

Our parquet is installed quickly and accurately with a simple installation system. In terms of maintenance, the floor needs regular maintenance and cleaning to maintain its appearance and quality. We provide detailed installation guidelines and maintenance recommendations to help customers properly use and maintain the floor.

Hot Searches