- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

ODMT

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

1800MM*1500*1300

-

Weight (KG):

-

1750

-

Application:

-

Bending, shearing, punching

-

Certification:

-

CE ISO

-

Keywords:

-

CNC busbar

-

Machine Type:

-

CNC Control

-

MOQ:

-

1set

-

Work Voltage:

-

380v

-

Delivery time:

-

14 Days

-

Package:

-

Plywood package

-

Max. punching pressure:

-

500Kn

-

Max. cutting thickness:

-

16mm

Quick Details

-

Max. Thickness (mm):

-

16 mm

-

Max. Width (mm):

-

250 mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

ODMT

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

1800MM*1500*1300

-

Weight (KG):

-

1750

-

Application:

-

Bending, shearing, punching

-

Certification:

-

CE ISO

-

Keywords:

-

CNC busbar

-

Machine Type:

-

CNC Control

-

MOQ:

-

1set

-

Work Voltage:

-

380v

-

Delivery time:

-

14 Days

-

Package:

-

Plywood package

-

Max. punching pressure:

-

500Kn

-

Max. cutting thickness:

-

16mm

Product Description

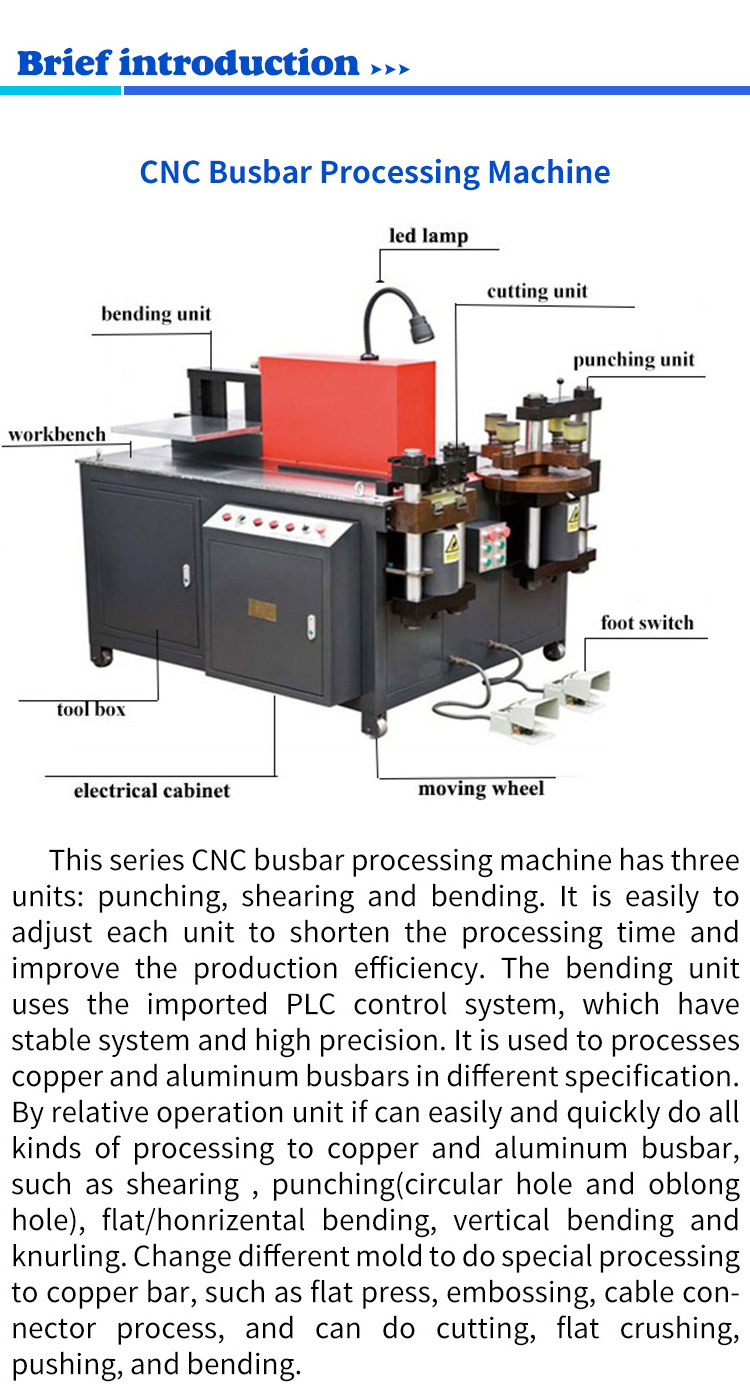

CNC busbar processing machine

has three units: punching, shearing and bending. It is easily to adjust each unit to shorten the processing time and improve the production efficiency. The bending unit uses the imported PLC control system, which have stable system and high precision. It is used to processes copper and aluminum busbars in different specification. By relative operation unit if can easily and quickly do all kinds of processing to copper and aluminum busbar, such as shearing , punching(circular hole and oblong hole), flat/honrizental bending, vertical bending and knurling. Change different mold to do special processing to copper bar, such as flat press, embossing, cable connector process, and can do cutting, flat crushing, pushing, and bending.

Impact pressure:7.0T

Power source:Hydropneumatic

Voltage:220V,50Hz

Total travel:100mm

Compressed air source need:3bar-8 bar

Weight:500KG

Max.thickness of single layer clinching:0.2mm~2.5mm

Technical parameter

|

Function

|

Item

|

|

HMX-303SK

|

HMX-503SK

|

|

|

Punching

|

(KN)

|

Max.strengt

|

300

|

500

|

|

|

|

(mm)

|

Diameter range

|

Φ4.3~Φ25

|

Φ4.3~Φ34

|

|

|

|

(mm)

|

Max.thickness

|

12

|

16

|

|

|

|

(mm)

|

Max.width

|

150

|

250

|

|

|

Shearing

|

(mm)

|

Max.shearing thickness

|

12

|

16

|

|

|

|

(mm)

|

Max.shearing width

|

150

|

250

|

|

|

Honrizental bending

|

(Kn)

|

Max.strength

|

300

|

500

|

|

|

|

(mm)

|

Max.width

|

150

|

250

|

|

|

|

(mm)

|

Max.thickness

|

12

|

16

|

|

|

Vertical bending

|

(mm)

|

Max.width

|

100(10mm厚)

|

120(10mm厚)

|

|

|

|

(degree)

|

Min.angle

|

90º

|

90º

|

|

|

Dimension

|

(mm)

|

|

1500x1300x1200

|

1800x1500x1300

|

|

|

Power

|

(kw)

|

|

3x4kw

|

3x5.5kw

|

|

|

Weight

|

(kg)

|

|

1250

|

1750

|

|

|

CNC precision

|

(degree)

|

Bending precision

|

±1º

|

±1º

|

|

|

|

(degree)

|

Repeat Bending precision

|

±0.3º

|

±0.3º

|

|

Part of Machine

Feature of Machinery

The shearing unit

adopts the universal frustration shearing, the cutting is smooth without burrs, the appearance is beautiful, and the cutting is free of waste.

T

he punching unit

uses a united six-mode turnplate in tooth shape to make sure the upper mold and the lower mold are absolutely in the center, improve the mold concentricity and extend the working life.

The turnplate is in tooth shape with a good view and high strength.No need to frequently change molds, labor intensity is highly reduced. It is easy and quick to use. Producing efficiency is obviously higher than a traditional one.

The bending unit

uses a double-decker working table, which can make sure that three working positions can do their operations at the same time without bothering the others. By changing different mold it can do flat bending and verticle bending.CNC controls the bending angle by an imported PLC control system. Input a busbar thickness and an angle on a CNC touching screen, or input height and a side length to get the result what you need, such as Z bending. Bending precision is ±1,repeat precision ±0.3.

Product Show

Company Profie

Exhibition

FAQ

Q1: How is quality ensured about the busbar processing machine?

our factory Passed the ISO-9001 quality certificationp, we have one year's quality warranty..

Q2: Can customized machines be purchased?

Yes, it can be provided according to the drawings and customer requirements

Q3: How many years of production experience and customer market experience do you have?

We have more than 10 years of production experience, we are agents and end customers direct sales company

Q4: How about the payment term?

30% advance payment, final payment before delivery, full payment for delivery.

our factory Passed the ISO-9001 quality certificationp, we have one year's quality warranty..

Q2: Can customized machines be purchased?

Yes, it can be provided according to the drawings and customer requirements

Q3: How many years of production experience and customer market experience do you have?

We have more than 10 years of production experience, we are agents and end customers direct sales company

Q4: How about the payment term?

30% advance payment, final payment before delivery, full payment for delivery.

Hot Searches