Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

GS-mach

-

Voltage:

-

220v/380v 50/60hz 3p

-

Dimension(L*W*H):

-

30*4.5*5m

-

Power (kW):

-

180

-

Weight:

-

30000 KG

-

Name:

-

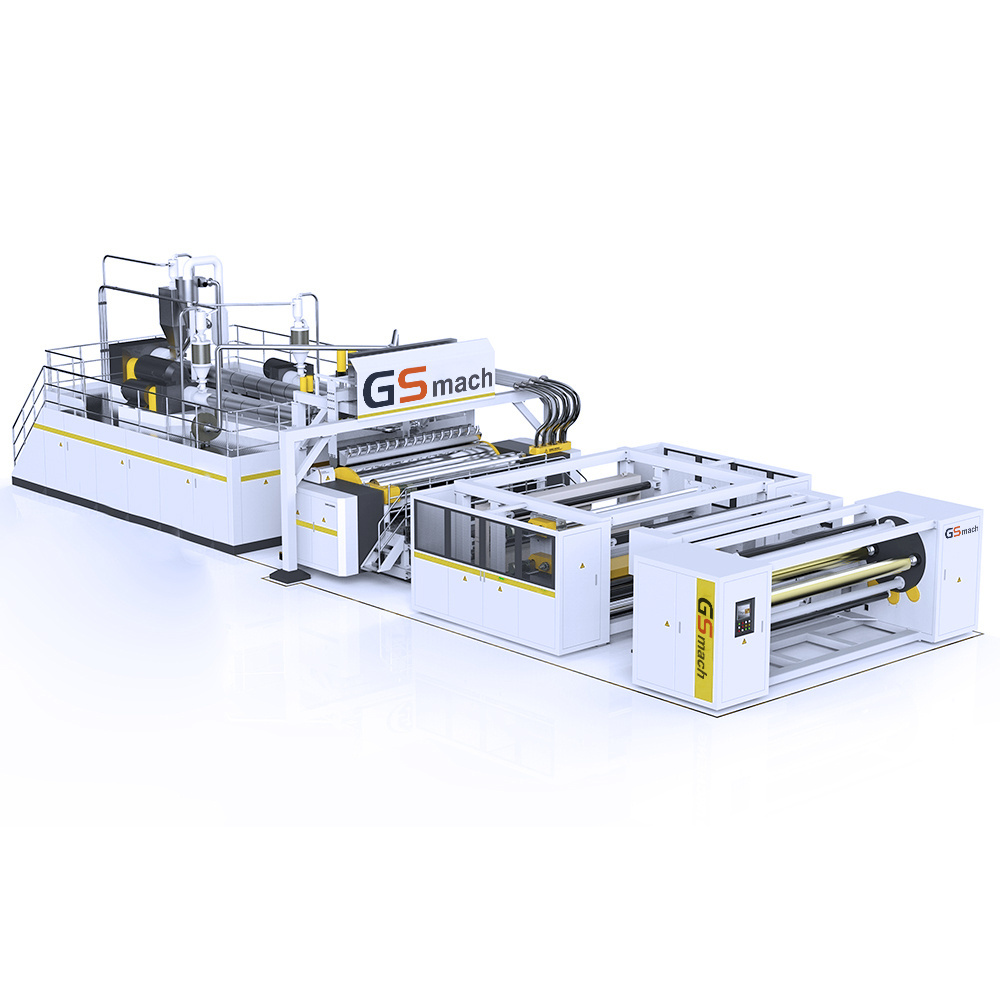

EVA Solar Cell Film Production Line 1200mm EVA Sheet Production Machin

-

Raw material:

-

EVA POE

-

Product width:

-

1250~2500mm

-

Product thickness:

-

0.2~1mm

-

Max speed:

-

5~15m

-

Certification:

-

CE ISO9001

-

Warnty:

-

1 year

-

Usage:

-

Casting film

-

Color:

-

Customer Choice

-

Final product:

-

Film

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

40:1

-

Screw Speed (rpm):

-

600 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

GS-mach

-

Voltage:

-

220v/380v 50/60hz 3p

-

Dimension(L*W*H):

-

30*4.5*5m

-

Power (kW):

-

180

-

Weight:

-

30000 KG

-

Name:

-

EVA Solar Cell Film Production Line 1200mm EVA Sheet Production Machin

-

Raw material:

-

EVA POE

-

Product width:

-

1250~2500mm

-

Product thickness:

-

0.2~1mm

-

Max speed:

-

5~15m

-

Certification:

-

CE ISO9001

-

Warnty:

-

1 year

-

Usage:

-

Casting film

-

Color:

-

Customer Choice

-

Final product:

-

Film

EVA Foam Extrusion Coating Lamination Making Machine EVA Solar Cell Film Production Line 1200mm EVA Casting Film Machinery

Product Overview

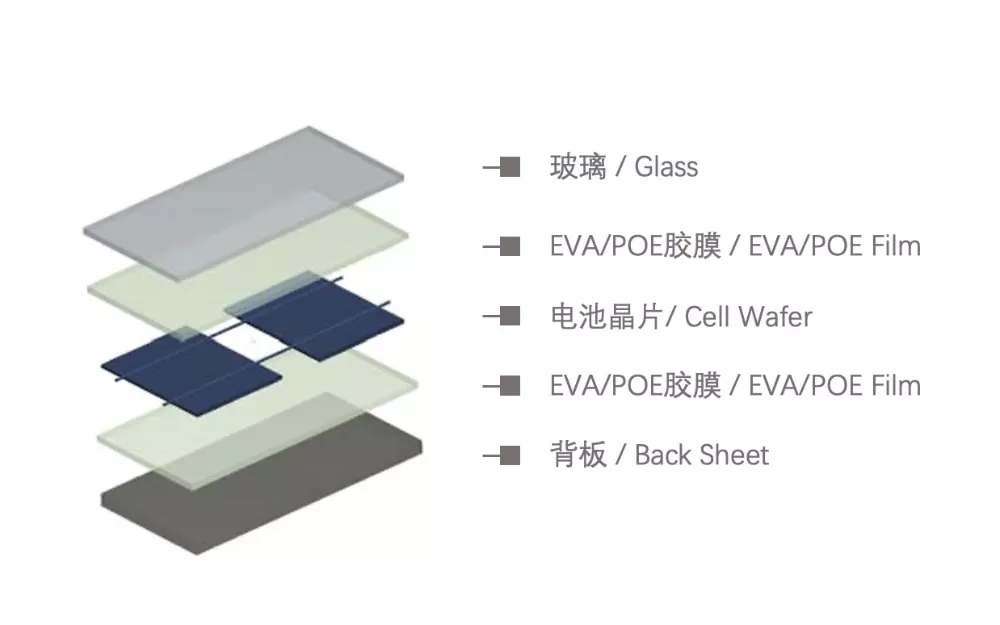

Green energy is the most talked-about topic at present. Undoubtedly, solar energy becomes an outstanding one of the. Global solar energy products has developed by over than 45% annually in the past decade. The development and investment of solar energy of China exceeded the world average.

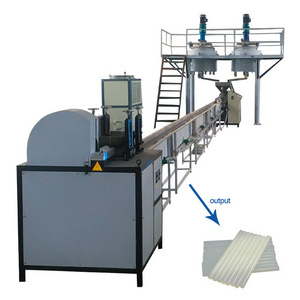

GS-mach has provided several complete production lines of EVA / POE solar cell encapsulation

film for well-known domestic solar cell manufacturers.

film for well-known domestic solar cell manufacturers.

|

Line type

|

600MW EVA/POE Solar Cell Encapsulatoin Line

|

300MW EVA/POE Solar Cell Encapsulatoin Line

|

|

Raw material

|

EVA Content: 25-33% / POE

|

EVA Content: 25-33% / POE

|

|

Output

|

400~500 kg/hr

|

300~350 kg/hr

|

|

Film in area

|

6,000,000 m2/year

|

4,320,000 m2/year

|

|

Encapsulating Capacity

|

500MW/year

|

300MW/year

|

|

Line Speed

|

5~15 m/min

|

5~15 m/min

|

|

Film Thickness

|

0.3-1mm

|

0.3-1mm

|

|

Film Width

|

2500mm

|

1250mm / 2500mm

|

|

Film Roller Dia

|

300-400mm

|

300-400mm

|

Process Principle

|

Machine Composition

|

|

|

||

|

Model

|

Machine

|

Quantity

|

||

|

1

|

Parallel Twin Screw Extruder

|

1 set

|

||

|

2

|

Left and right distributor

|

1 set

|

||

|

3

|

Hydraulic fast changing device

|

1 set

|

||

|

4

|

Melt pump

|

1 set

|

||

|

5

|

Die internal compound die head

|

1 set

|

||

|

6

|

Three-roll calender

|

1 set

|

||

|

7

|

Independent temperature control device type

|

1 set

|

||

|

8

|

Drying unit

|

1 set

|

||

|

9

|

Slow cooling device

|

1 set

|

||

|

10

|

Trimming device

|

1 set

|

||

|

11

|

Traction device

|

1 set

|

||

|

12

|

Winding device

|

1 set

|

||

|

13

|

Thickness gauge unit

|

1 set

|

||

|

14

|

The PLC computer control

|

1 set

|

||

Hot Searches