- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Shiwei

-

Model Number:

-

TYMC-1100

-

Usage:

-

Box

-

Dimensions(L*W*H):

-

2080*2050*1900mm

-

Weight:

-

4900 KG

-

Platen Size:

-

1100*800mm

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Foil feeding groups:

-

3 groups

-

Max. working speed:

-

23±2s/min

-

Function:

-

foil stamping die cutting

-

function2:

-

embossing debossing

-

Application:

-

leather cover

-

Application2:

-

PVC PP

-

Max working size:

-

1100*800mm

-

Individual heating zones:

-

5 zones

Quick Details

-

Condition:

-

New

-

Plate Type:

-

Flatbed Printer

-

Color & Page:

-

Multicolor

-

Voltage:

-

380V

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Shiwei

-

Model Number:

-

TYMC-1100

-

Usage:

-

Box

-

Dimensions(L*W*H):

-

2080*2050*1900mm

-

Weight:

-

4900 KG

-

Platen Size:

-

1100*800mm

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Foil feeding groups:

-

3 groups

-

Max. working speed:

-

23±2s/min

-

Function:

-

foil stamping die cutting

-

function2:

-

embossing debossing

-

Application:

-

leather cover

-

Application2:

-

PVC PP

-

Max working size:

-

1100*800mm

-

Individual heating zones:

-

5 zones

PRODUCT FEATURES

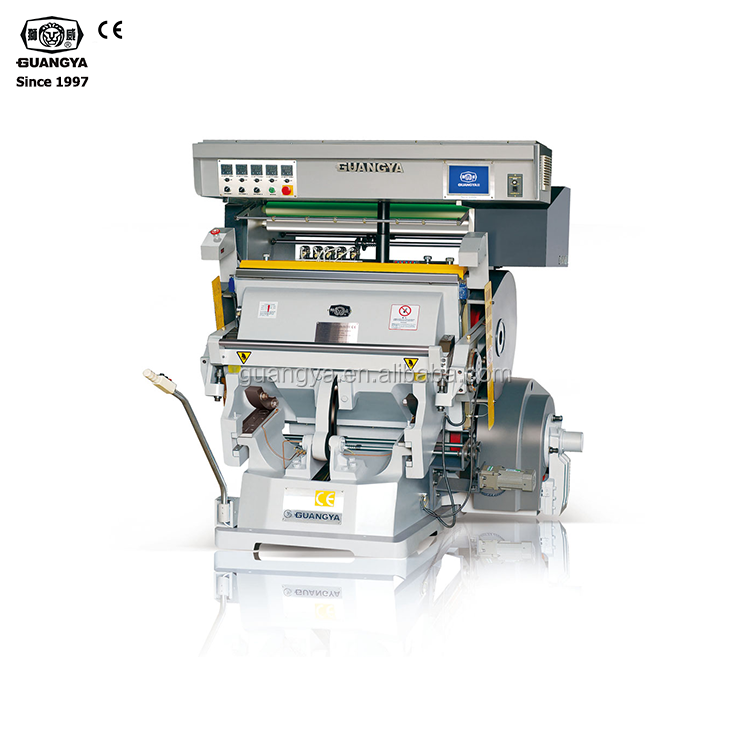

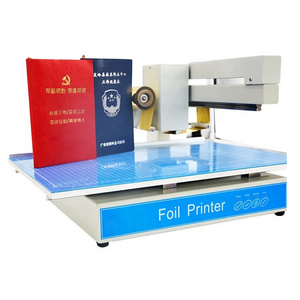

Manual hot foil stamping and die-cutting machine is the ideal equipment for stamping and die-cutting all kinds of paperboard, leather, plastic, and so on. This machine is the ideal equipment for printing factories.

A manual Foil Stamping Machine is one kind of basic stamping machine for sampling and customizing products. Increasing and decreasing temperature accurately, changing the stamping plate easily, operating easily and perfect protection system are the main reason which can win the market. it is also the perfect model for embossing and creasing, suitable for many kinds of different-weight cardboard.

Our “SHIWEI” brand TYMC series Manual Foil Stamping and Die Cutting Machine is widely used in the post-press industry, this platen converts paper, carton board, heavy solid board, semi-rigid plastic, corrugated into different products with high efficiency, such as food/beverage/ personal care/ home&office/ industrial package and so on.

As a professional manufacturer of hot stamping die-cutting machines with a long history, GUANGYA - SHIWEI has laid the foundation for current mainstream manual foil stamping and die-cutting machines in the market.

1.TYMC series hot foil stamping and die cutting machine is very versatile, with the functions of hot stamping, die cutting,creasing and concave-convex forming and so on.

2. The display system with LCD screen greatly improves the productivity.

3. All the casting are treated with annealing. it will reduce the wear of machine.

4. This machine adopts PLC microcomputer control from Japan, stepper motor drive for reliable operation and convenient adjustment.

5. The heating plate divided into 5 zones, and each zone can be adjusted independently.Fast heating, low-energy, constantly temperature control, real-time temperature display which will ensure high product quality.

TECHNICAL PARAMETER

|

TYMC-1100

|

PLC Control Foil Stamping Die Cutting Machine

|

|

Max. effective plate area

|

1100 X 800 mm

|

|

Max. stamping size

|

1100 X 800 mm

|

|

Groups of foil feeding

|

3

|

|

Max. foil feeding length

|

800mm

|

|

Leapfrogging scope

|

0-99

|

|

Individual zones of heating plate

|

5

|

|

Power of heating plate

|

15kw

|

|

Speed

|

23±2 sheets/min

|

|

Main motor power

|

5.5KW 6pole

|

|

Total Power

|

20.5kw

|

|

Gross Weight Of Machine

|

4900kg

|

|

Overall Machine Dimentions

|

2080 X 1950 X 2200 mm

|

MAIN FEATURES

Main Host

• Highest strength casting iron, strong, stable and sturdy

• All the castings are treated with annealing, which will reduce the wear of the machine

• Pressure micro adjustment device, easy for setting up

• Excellent workmanship, quality assurance

• Good appearance and design concept

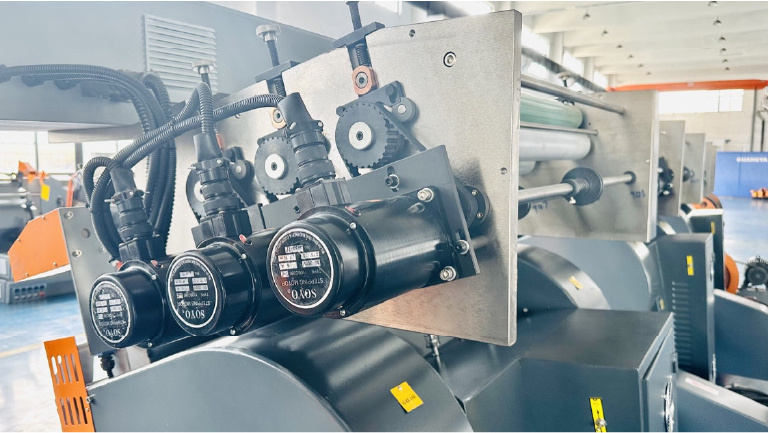

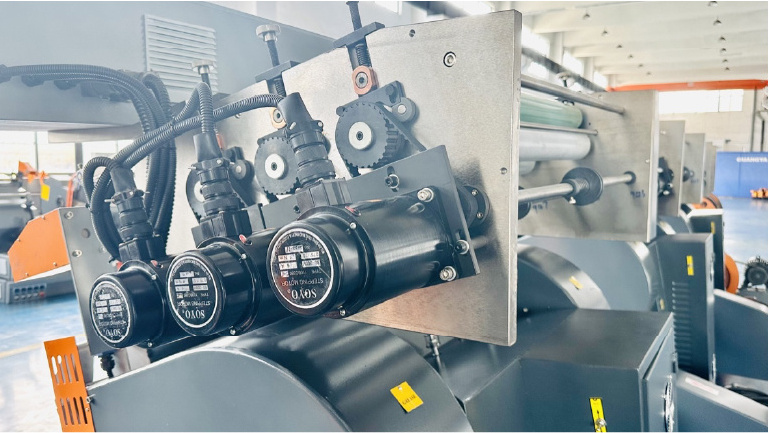

Foil Stamping System

• 3 foil shafts, easy to set up

• 5 foil stamping zone,individual controlled, save energy

• Constantly temperature control, real-time temperature display, which ensures high product quality

• Up to 99 foil stepping scope, which can solve different foil die patterns and save foils

• Controlled by imported PLC system,reliable and faster in operation

Safety System

• Inferred sensor to protect the operator's safety, it is very sensitive and responds quickly

• Several sensors can control the machine’s stop, which ensures the safety of the operator.

• Safety door (option)

Lubrication System

• Automatic centralized lubrication system

• The frequency of lubricating can be adjusted

• Easier for maintenance

Control System

Operating System

• Delay function can control machine open and ceasing time.

• Equipped with LCD screen, easy to operate

Electrical System

• Modular design of electrical system

• CE standard electric system

• Imported electrical appliances, quality assurance

*FOR MORE DETAILS, PLEASE ASK 0086 13566203885 Climy

SAMPLES

ABOUT US

Pre-Sales Service

* Inquiry and consulting the support

* Testing support in our factory

* Inspect machine in our Factory

* Testing support in our factory

* Inspect machine in our Factory

After-Sales Service

* Training how to install the machine, training how to use the machine

* Engineers available to service machinery overseas

* Engineers available to service machinery overseas

PROCESSING EQUIPMENT

DELIVERY

CERTIFICATIONS

THE UNIQUE HUMAN CARE AND PROFESSION

PASSIONATE SALES SERVICE SYSTEM

We focus on customer service, all-year non-stop service, personal training, and so on.

Not only provide customer service. But also a pre-sales system, including solutions to product selection, storage of parts, technical guidance, operating training, exchange management platform, and so on.

Realizing the idea of focusing on customer success, creating value to customers.

Hot Searches