Longhe has been focusing on plastic

machinery for 36+ years

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Longhe

-

Voltage:

-

220V/380V or customized

-

Dimension(L*W*H):

-

2800x1300x2600mm

-

Weight (KG):

-

730 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Machinery:

-

Auger Screw Feeding Machine

-

lifting capacity:

-

1000-3000kg/h

-

Material tank:

-

50-100kg

-

Motor power:

-

1500w

-

Upper material height:

-

1900mm (also can be customed)

-

Frame Material:

-

Carbon Steel

-

Contact parts materials:

-

stainless steel

Quick Details

-

Power:

-

1.5KW

-

Warranty:

-

1 Year

-

Width or Diameter:

-

68mm

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Longhe

-

Voltage:

-

220V/380V or customized

-

Dimension(L*W*H):

-

2800x1300x2600mm

-

Weight (KG):

-

730 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Machinery:

-

Auger Screw Feeding Machine

-

lifting capacity:

-

1000-3000kg/h

-

Material tank:

-

50-100kg

-

Motor power:

-

1500w

-

Upper material height:

-

1900mm (also can be customed)

-

Frame Material:

-

Carbon Steel

-

Contact parts materials:

-

stainless steel

FOCUS ON MANUFACTURING

1988

FOUNDED IN 1988

35000m²

FACTORY FLOOR AREA

36+

YEARS EXPERIENCE

MORE THAN 15 YEARS OF SENIOR

TECHNICAL TEAM

Longhe enterprises focus on supporting advanced equipment and pay more attention to talent training, with an average time in Longhe more than 15 years of professional technical service team

Professional technology focus

on research and development

Factory environment · Live shooting

OVER 150000+ CUSTOMERS

IN 36+ YEARS CHOOSE Longhe

Product Description

INTELLIGENT AUTOMATIC

FEEDING

Stainless steel screw feeder

Product Details

Other larger itineraries can be customized please consult customer service

|

model

|

SS-3M

|

Pipe diameter

|

68mm

|

|

Lifting capacity (kg/h)

|

1000-3000

|

Material Tank

|

50-100kg

|

|

Upper materlal helght

|

1900mm

|

Motor power (kw)

|

1.5

|

WORKING PRINCIPLE

Screw feeding machine is drived by motor power and cycloidal reducer to screw,

is a kind of screw rotation to make the material forward

extrusion, while making the material forward push, screw feeding

from the feed port feed through the screw forced material to the

discharge port, the machine can be used independently for mixing

machine, injection molding machine and other equipment with a

certain height requirements of automatic feeding.

Application Range

WIDE USES

Suitable for grading and screening of granular materials. The inclination is adjustable. Widely used in extrusion granulation, chemical industry, feed screening and other industries.

Product advantages

MICROCOMP

UTER CONTROL PANEL

INTELLIGENT CONTROL SYSTEM

Automatic feeding, automatic stop; Real-time personalized setting, set when feeding,

equipped with safety braking system; Easy to operate.

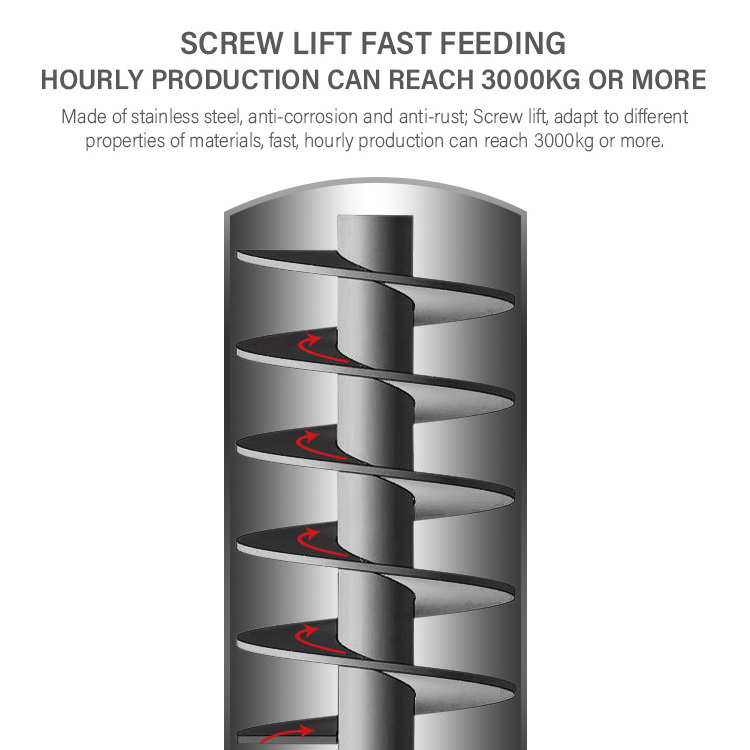

SCREW LIFT FAST FEEDING

HOURLY CAPACITY

CAN REACH 3000KG OR MORE

Made of stainless steel, anti-corrosion and anti-rust; Screw lift, adapt to different properties of materials, fast, hourly

capacity

can reach 3000kg or more.

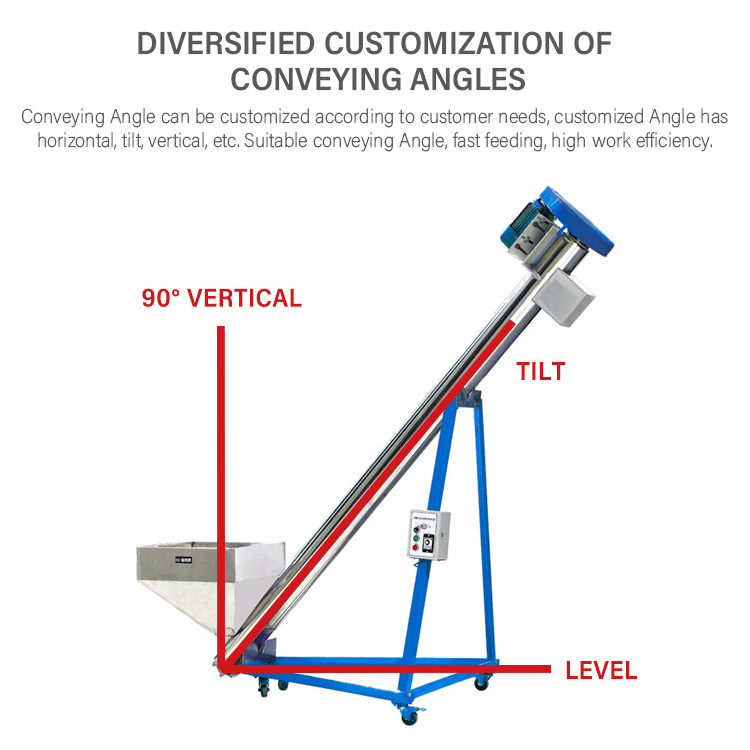

DIVERSIFIED CUSTOMIZATION OF

CONVEYING ANGLES

Conveying Angle can be customized according to customer needs, customized Angle has horizontal, tilt, vertical, etc. Suitable conveying Angle, fast feeding,

high efficiency work

MOBILE MUTE UNIVERSAL WHEEL TRIPOD

The mobile screw feeder is easy to install and can be moved, such as multiple mixers using the same material, only one machine can be supplied at the same time, eliminating the trouble of manual feeding, working safer and more efficient.

TAILOR-MADE

ONE TO ONE CUSTOMIZED SYSTEM SOLUTION

For you to design special performance, non-standard structure equipment, one to one customization to provide a full range of solutions.

Machine detail

Always insist on good quality,details determine success or failure

Machine maintenance

|

COMPONENT

|

Maintenance method

|

|

spiral

|

Clean up immediately after use

|

|

Outlet/inlet material port

|

Clean up immediately after use

|

|

Electric box

|

Clean up dust regularly

|

|

fastener

|

Check the tightness regularly and lock it

|

|

Long downtime

|

Long downtime needs to be cleaned up

|

Hot Searches