- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

±0.1g

-

Applicable Industries:

-

Other, Loose Dry,eyeshadow,Color cosmetic

-

Voltage:

-

AC220V

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Cosmetic

-

Dimension(L*W*H):

-

4660*2825*2305mm

-

Weight:

-

1200 KG

-

Product name:

-

lipstick mold filling production line

-

Keywords:

-

Lipstick Heating Making Filling Machine

-

Outer dimension:

-

4660*2825*2305mm

-

Power:

-

17KW

-

Lipstick shape:

-

Water Drop, Nail Drop, Moon Drop (According to product)

-

Air supply:

-

0.6-0.8MPa, ≥300L/min

-

Output:

-

2160-3600 pcs/hour

-

Function:

-

Automatic Filler

-

Suitable for:

-

LIPSTICK/LIP BALM

-

Filling nozzles:

-

2/4/6/8/10/12(customized)

Quick Details

-

Machinery Capacity:

-

Other

-

Packaging Material:

-

Plastic

-

Filling Material:

-

Powder

-

Filling Accuracy:

-

±0.1g

-

Applicable Industries:

-

Other, Loose Dry,eyeshadow,Color cosmetic

-

Voltage:

-

AC220V

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Cosmetic

-

Dimension(L*W*H):

-

4660*2825*2305mm

-

Weight:

-

1200 KG

-

Product name:

-

lipstick mold filling production line

-

Keywords:

-

Lipstick Heating Making Filling Machine

-

Outer dimension:

-

4660*2825*2305mm

-

Power:

-

17KW

-

Lipstick shape:

-

Water Drop, Nail Drop, Moon Drop (According to product)

-

Air supply:

-

0.6-0.8MPa, ≥300L/min

-

Output:

-

2160-3600 pcs/hour

-

Function:

-

Automatic Filler

-

Suitable for:

-

LIPSTICK/LIP BALM

-

Filling nozzles:

-

2/4/6/8/10/12(customized)

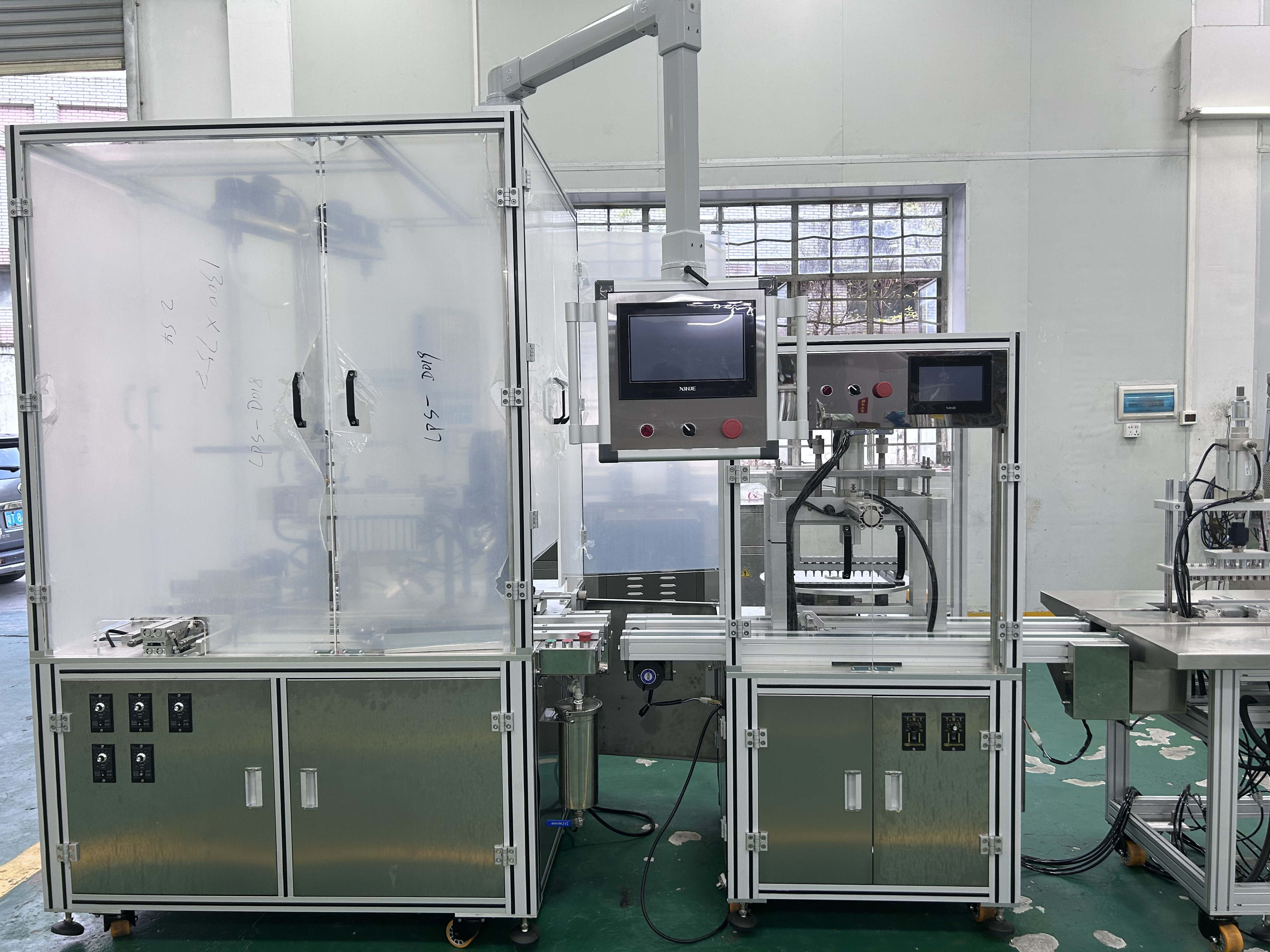

Silicone mold cosmetic lipstick/lip balm heating cooling forming filling capping machine lipstick lip balm making machine

Products Description

Introduction

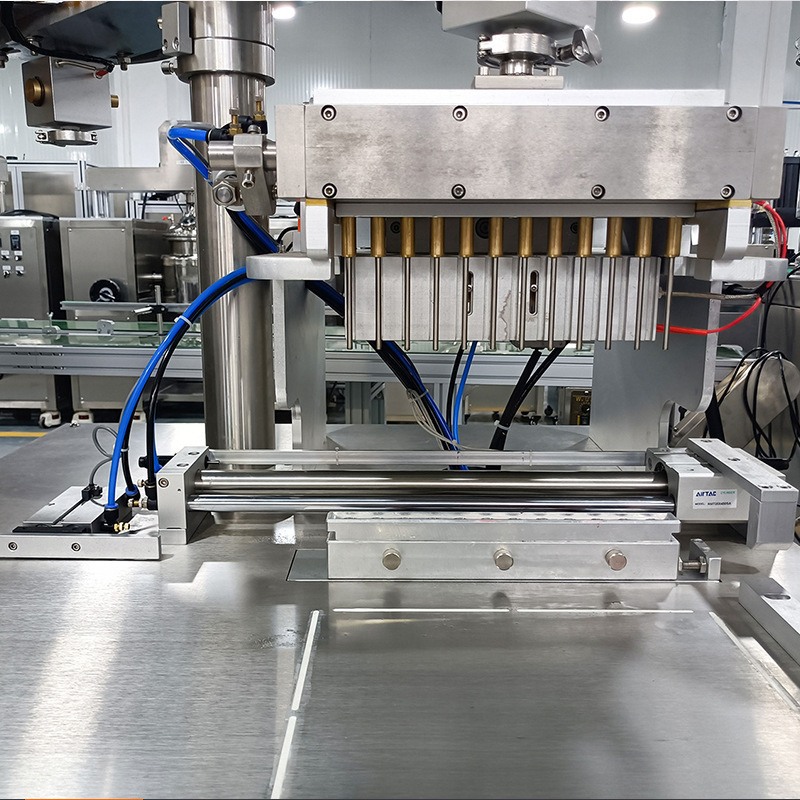

This machine is made of stainless steel, it is durable and widely use for many kinds of lipstick. It fill 12 pcs per time, and available to switch into 10 or 6 nozzles. This machine is filling with silicone mold or metal mold, and have preheating system for metal mold.

Features

1) 20L double tank,with SUS304 material,and the contact parts is SUS316L material.Three layers tank with heating and stirring.

2) Fill 12 pcs each time.

3)Servo drive filling to ensure filling accuracy.

4)Servo drive lifting.

5)Having auto pre-filling before filling into mold to remove the hardened material in filling nozzle.Having waste material

collection pan.

6)Mold preheating system.

Technical Data

|

Production capacity

|

Power supply

|

Filling range

|

Compressed air

|

|

5-6 molds/min.

|

AC220V/1P/50Hz, 7KW

|

1-14ml

|

6Kg/cm2

|

|

Desktop height

|

Weight

|

Tank volume

|

Filling accuracy

|

|

620mm

|

280KG

|

20L*2 stainless steel barrel.

|

±1%

|

Details Images

Working Principle

Recommend Products

Application

Hot Searches