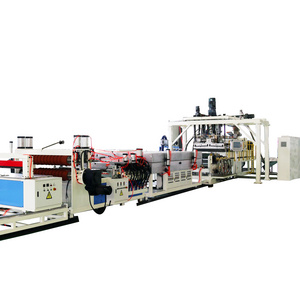

barrier properties, does not contain other additives, is pure and hygienic, has good toughness and extensibility, and has excellent recyclability.

PET sheet can be widely used in various packaging and printing industries such as electrical appliances, toys, food, medicine, etc.