1.

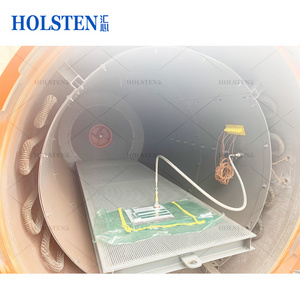

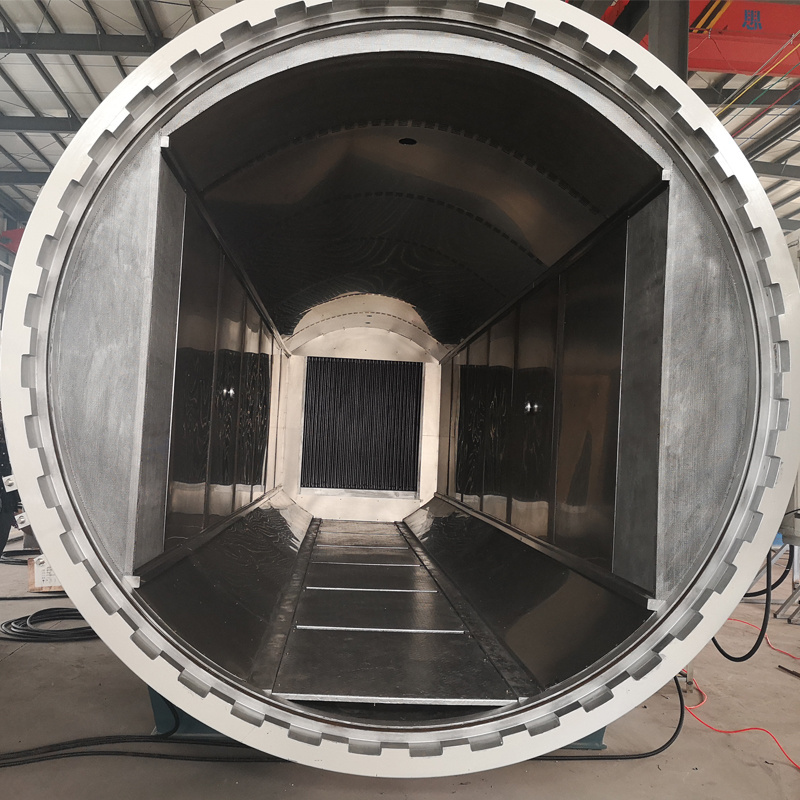

Adopting new heating technology

, the heating element is surrounded by four sides, strong wind convection cycle design, to achieve temperature balance in the autoclave, to ensure product quality, save energy and improve production efficiency.

2. Touch screen, PLC and other

electrical appliances are equipped with international brands

such as Siemens, South Korea LS, etc., with paper recording and data storage functions, real-time monitoring of temperature and pressure changes in the autoclave. Temperature and pressure with interlock control function, automatic temperature compensation, pressure compensation, to ensure pressure and temperature stability.

3.

Unique cooling technology

of high, middle and low grades can adjust the cooling speed according to the needs of customers or products to ensure the yield. As a main cooler, the fin heat exchanger has a large heat dissipation area and high heat exchange efficiency.

4.

Device software can realize data exchange

, output and storage. Call more than 40 sets of process parameters. With fault alarm and other functions.

5.

Use 80mm environmentally friendly aluminum silicate insulation material

, superior thermal insulation performance and reduce energy consumption.

6.

All lines adopt the external wiring mode

, which effectively prevents aging problems caused by excessive temperature in the furnace, prolongs the life of the line, and facilitates equipment maintenance and overhaul.

7.

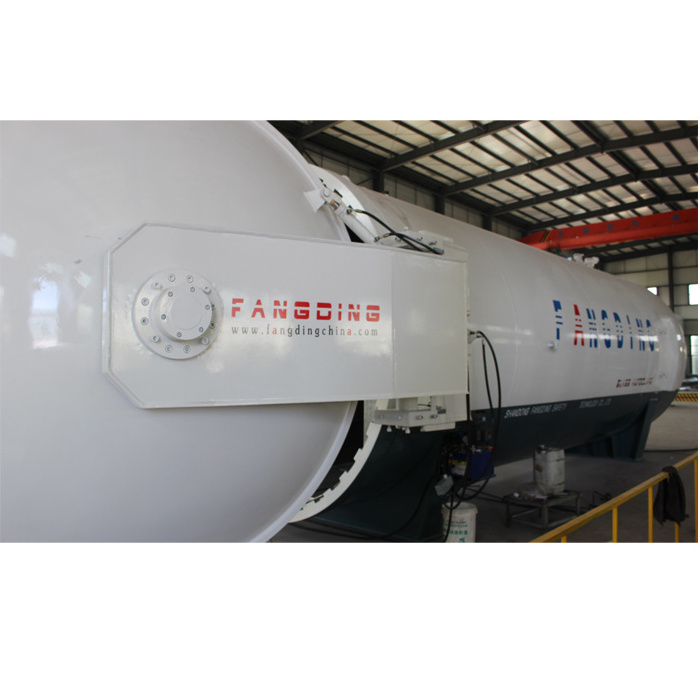

Our company has the qualification of pressure vessel production,

and the welding employs a senior technician with a certificate. Before leaving the factory, it is strictly inspected according to the pressure vessel inspection standard.

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Fangding

-

Voltage:

-

220V-440V

-

Power:

-

457kw

-

Dimension(L*W*H):

-

3000*8000mm

-

Weight:

-

23500kg

-

Name:

-

High temperature high pressure vessel laminated glass autoclave

-

Usage:

-

glass laminating

-

Max glass size:

-

3000*8000mm

-

Control system:

-

Siemens PLC

-

Advanced function:

-

Finned heating tube / high power fan / four-sided heating design

-

Application range:

-

Doubel Glass

-

Glass thickness:

-

6-60mm

-

Processable glass type:

-

Normal Glass

-

Glass machine:

-

Pvb Laminated Glass Machine

-

Interlayer film:

-

PVB

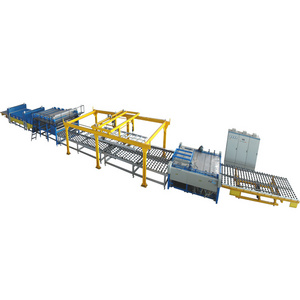

Quick Details

-

Machine Type:

-

Glass Laminating Machine

-

Glass Thickness:

-

3-19mm

-

Production Capacity:

-

100%

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Fangding

-

Voltage:

-

220V-440V

-

Power:

-

457kw

-

Dimension(L*W*H):

-

3000*8000mm

-

Weight:

-

23500kg

-

Name:

-

High temperature high pressure vessel laminated glass autoclave

-

Usage:

-

glass laminating

-

Max glass size:

-

3000*8000mm

-

Control system:

-

Siemens PLC

-

Advanced function:

-

Finned heating tube / high power fan / four-sided heating design

-

Application range:

-

Doubel Glass

-

Glass thickness:

-

6-60mm

-

Processable glass type:

-

Normal Glass

-

Glass machine:

-

Pvb Laminated Glass Machine

-

Interlayer film:

-

PVB

Product Overview

FEATURES AT A GLANCE

Right elevation

Left elevation

Front elevation

PRODUCT SPECIFICATIONS

|

No

|

Item

|

Data

|

|

1

|

Process glass size

|

3000x8000mm

|

|

2

|

Power

|

330KW

|

|

3

|

Operating weight

|

25 tons

|

|

4

|

Operating weight

|

0-160℃

|

|

5

|

Operating system

|

Siemens PLC

|

|

6

|

Glass thickness

|

2-19mm

|

|

7

|

Dimension

|

13000*7500*7500mm

|

|

8

|

Floor space

|

13000*7500mm

|

|

9

|

Production capacity

|

500-800㎡/cycle

|

|

10

|

Interlayer

|

PVB/TPU/SGP film

|

Company & Exhibition

Fangding Technology Co., Ltd. is located in a charming coastal city -- Rizhao, Shandong province, which is a high-tech enterprise mainly

specializing in R&D, production and sales & service of the laminated glass machinery and the interlayer films, the The main products are

EVA laminated glass machine, Heat Soak Furnace, Smart PVB glass laminating line and EVA, TPU, SGP films.

We have successively obtained CCC certification of EVA laminated glass, CE certification of European Union, Canadian CSA certification, and successfully obtained ISO 9001:2015 international quality management system certification etc.

Fangding always adhere to the Market-Oriented, Customer-Centric business philosophy, is committed to providing the best quality service for new and old customers, and supplying the full set of laminated glass technology solutions for glass processing enterprises.The company has a comprehensive R&D center, which can set laminated glass equipment R&D and laminated glass processing and test in one, can also provide the full set of solutions of laminated glass from material processing to finished product inspection. Our products are sold to 68 countries and regions and are welcomed by new and old customers at home and abroad.

Fangding always adhere to the Market-Oriented, Customer-Centric business philosophy, is committed to providing the best quality service for new and old customers, and supplying the full set of laminated glass technology solutions for glass processing enterprises.The company has a comprehensive R&D center, which can set laminated glass equipment R&D and laminated glass processing and test in one, can also provide the full set of solutions of laminated glass from material processing to finished product inspection. Our products are sold to 68 countries and regions and are welcomed by new and old customers at home and abroad.

SIMILAR PRODUCTS

FAQ

Q: Could your machines laminate bent glass?

A: Yes. There are reserved vacuum lines inside the autoclave. You can laminate large-size bent glass in one step, which is very easy to operate.

Q: When will your machine ready for delivery after our prepayment?

A: It depends on your requirements. Usually it will take 120 days after receiving deposit.

Q: What about the terms of payment?

A: Normally 30% prepayment, 65% before shipment by T/T, balance 5% should be paid during installation and commissioning. L/C and other terms are also available.

Q: How long it will take to finish one cycle?

A: Yes. There are reserved vacuum lines inside the autoclave. You can laminate large-size bent glass in one step, which is very easy to operate.

Q: When will your machine ready for delivery after our prepayment?

A: It depends on your requirements. Usually it will take 120 days after receiving deposit.

Q: What about the terms of payment?

A: Normally 30% prepayment, 65% before shipment by T/T, balance 5% should be paid during installation and commissioning. L/C and other terms are also available.

Q: How long it will take to finish one cycle?

A: It will need 2-4 hours,

depends on your loading rate.

Q: Does you machine have any certifications?

A: Yes, we have CE certificate. Especially for autoclave, we have "Manufacture License of Special Equipment", which is rarely owned by others suppliers.

Q: How to operate the machine? Is it difficult?

A: No, our machine is very easy to operate. The machine will work automatically after you set the parameters through the touch screen. We will send experienced senior engineers to teach you operating skills and production experience until you are proficient in operation.

A: No, our machine is very easy to operate. The machine will work automatically after you set the parameters through the touch screen. We will send experienced senior engineers to teach you operating skills and production experience until you are proficient in operation.

Q: What is the maximum glass size?

A: Normally we have size 2500x5000mm, 2500x6000mm, 3000x6000mm, 3000x8000mm.

Custom sizes are also accepted

Hot Searches