- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

zhongde

-

Dimension(L*W*H):

-

Depends on capacity

-

Weight:

-

2500 KG

-

Working Temperature Range:

-

20 - 300 ℃

-

Material:

-

Special steel pipe for boiler, Special steel pipe for boiler

-

Product name:

-

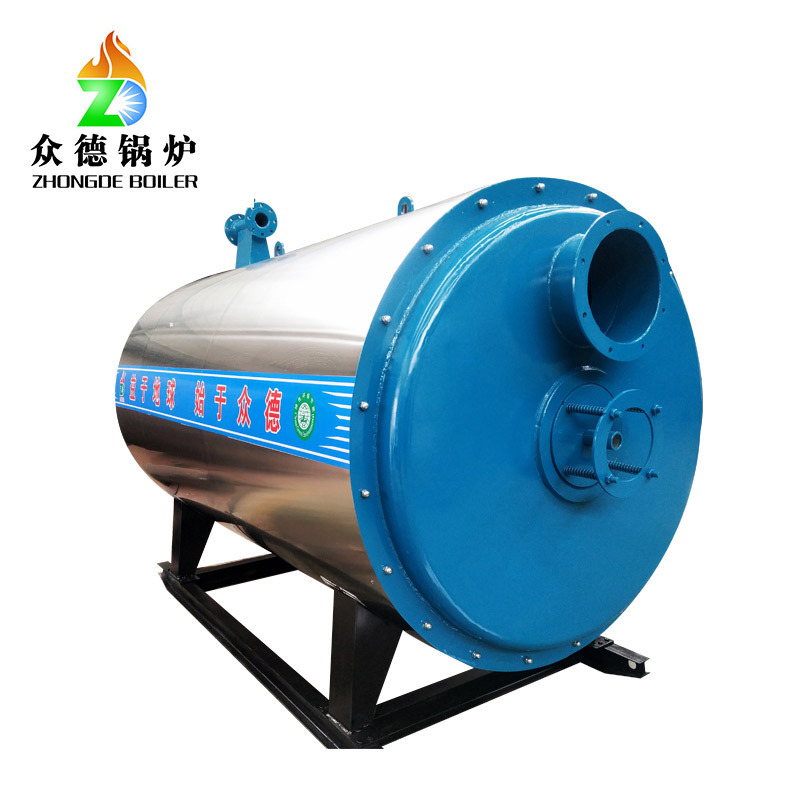

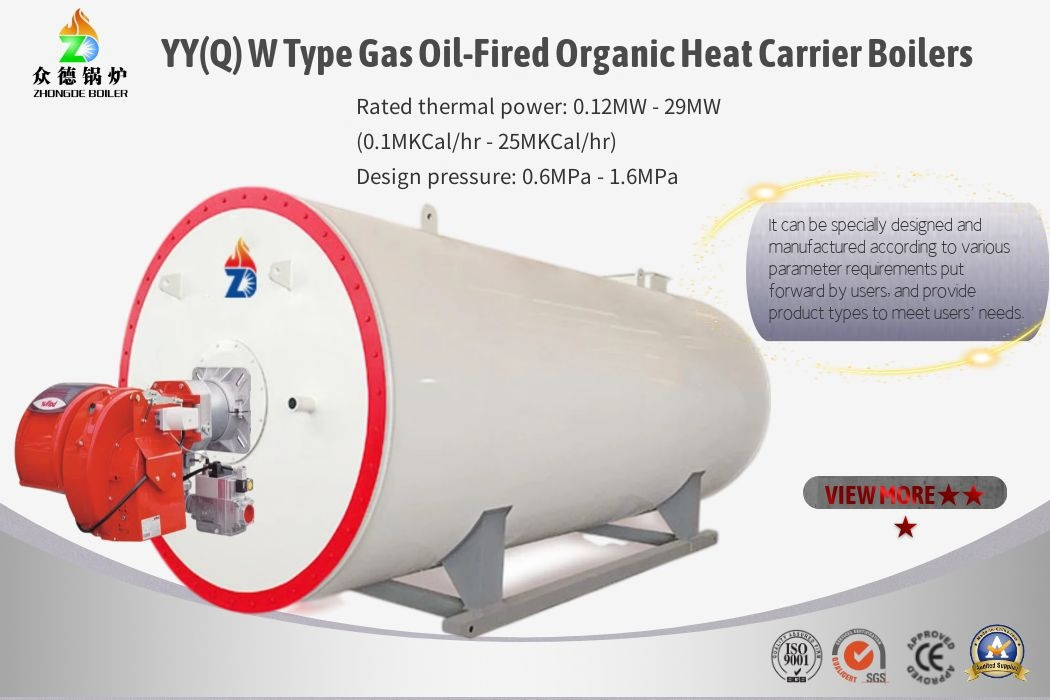

YYQW Fuel gas heat conduction oil furnace

-

Keywords:

-

Thermal oil boiler

-

Application:

-

Industrial Production

-

Application Field:

-

Building Materials

-

Function:

-

Multifunctional

-

Color:

-

Customers Requirment

-

Operation:

-

Easy Operation

-

Thermal efficiency:

-

96%

-

Steam temperature:

-

194 /204 /226

-

Showroom Location:

-

None

-

Type:

-

Bearing Heater

-

Marketing Type:

-

Ordinary Product

Quick Details

-

Power Source:

-

Gas or oil

-

Voltage:

-

220V/110V

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

zhongde

-

Dimension(L*W*H):

-

Depends on capacity

-

Weight:

-

2500 KG

-

Working Temperature Range:

-

20 - 300 ℃

-

Material:

-

Special steel pipe for boiler, Special steel pipe for boiler

-

Product name:

-

YYQW Fuel gas heat conduction oil furnace

-

Keywords:

-

Thermal oil boiler

-

Application:

-

Industrial Production

-

Application Field:

-

Building Materials

-

Function:

-

Multifunctional

-

Color:

-

Customers Requirment

-

Operation:

-

Easy Operation

-

Thermal efficiency:

-

96%

-

Steam temperature:

-

194 /204 /226

-

Showroom Location:

-

None

-

Type:

-

Bearing Heater

-

Marketing Type:

-

Ordinary Product

Product Description

1. The heat exchange surface of the boiler adopts spiral dense discharge coil structure and three return structure of flue gas. Optimize space heat transfer intensity and strengthen convective heat transfer.

2. The heating surface is composed of double-layer or multi-layer spiral closely arranged coils. The inner coil is a combustion radiation heat exchange surface, and the gap between the inner coil and the middle coil or the outer coil forms a hot flue gas heat exchange surface.

3. Air heat exchanger or water / steam heat exchanger can be arranged at the tail of the boiler for waste heat absorption. The heating area is sufficient to reduce the exhaust gas temperature of the boiler and improve the thermal efficiency of the boiler.

4. High quality refractory and thermal insulation materials are used, which have high heat resistance, good thermal insulation effect, reduce heat loss and improve thermal efficiency.

5. The boiler heat exchange structure is matched with the burner to achieve high combustion efficiency and low pollutant emission, so as to ensure that NOx emission meets the environmental emission requirements of the place where the boiler is used.

Model YYW/YQW Rated Thermal Power 120-29000 KW

Design Pressure 1.1 Mpa

Working Pressure 0.8 Mpa

Medium Outlet Temperature ≤350 C

Fuel Light Oil,Heavy Oil,Natural Gas,Lpg,Lng,Cng,Diesel etc Application

Chemical,Oil,Petrochemical,Textile,Printing,Rubber,Carton,Plywood,Asphalt,Cement, etc

Fuel Light Oil,Heavy Oil,Natural Gas,Lpg,Lng,Cng,Diesel etc Application

Chemical,Oil,Petrochemical,Textile,Printing,Rubber,Carton,Plywood,Asphalt,Cement, etc

Product Datasets

|

MODEL

|

YY(Q)W- 120Y(Q)

|

YY(Q)W- 240Y(Q)

|

YY(Q)W- 350Y(Q)

|

YY(Q)W- 500Y(Q)

|

YY(Q)W- 700Y(Q)

|

YY(Q)W- 1000Y(Q)

|

YY(Q)W- 1200Y(Q)

|

YY(Q)W- 1400Y(Q)

|

|||||||

|

Rated power(KW)

|

120

|

240

|

350

|

500

|

700

|

1000

|

1200

|

1400

|

|||||||

|

Design pressure(Mpa)

|

1.1

|

|

|

|

|

|

|

|

|||||||

|

Rated working pressure(Mpa)

|

0.8

|

|

|

|

|

|

|

|

|||||||

|

Highest working temperature(℃)

|

320

|

|

|

|

|

|

|

|

|||||||

|

Furnace oil volume(m3/h)

|

0.1

|

0.21

|

0.3

|

0.4

|

0.56

|

0.8

|

1.0

|

1.3

|

|||||||

|

Circulation oil

volume(m3/h) |

9.6

|

19.4

|

28

|

32

|

60

|

65

|

80

|

90

|

|||||||

|

Pipe connection diameter(DN)

|

40

|

50

|

80

|

80

|

100

|

125

|

125

|

125

|

|||||||

|

Thermal Efficiency (%)

|

~95

|

|

|

|

|

|

|

|

|||||||

|

Size (m)

|

1.6x1.1

x1.52

|

2.5x1.4

x1.5

|

2.56x1.53x1.57

|

2.8x1.68

x1.68

|

3.24x1.47

x2.26

|

3.39x1.75

x2.36

|

4.07x2.1

x2.2

|

4.53x2.4

x2.35

|

|||||||

|

Weight (T)

|

2

|

2.9

|

3.7

|

4.5

|

4.9

|

5.5

|

6.5

|

7.5

|

|||||||

|

MODEL

|

YY(Q)W- 1800Y(Q)

|

YY(Q)W- 2100Y(Q)

|

YY(Q)W- 2400Y(Q)

|

YY(Q)W- 3000Y(Q)

|

YY(Q)W- 3500Y(Q)

|

YY(Q)W- 4200Y(Q)

|

YY(Q)W- 4700Y(Q)

|

YY(Q)W- 6000Y(Q)

|

|||||||

|

Rated power(KW)

|

1800

|

2100

|

2400

|

3000

|

3500

|

4200

|

4700

|

6000

|

|||||||

|

Design pressure(Mpa)

|

0.9

|

|

|

|

|

|

|

|

|||||||

|

Rated working pressure(Mpa)

|

0.8

|

|

|

|

|

|

|

|

|||||||

|

Highest working temperature(℃)

|

320

|

|

|

|

|

|

|

|

|||||||

|

Furnace oil volume(m3/h)

|

1.5

|

1.7

|

2

|

2.4

|

3

|

4

|

4.5

|

7.8

|

|||||||

|

Circulation oil

volume(m3/h) |

100

|

120

|

160

|

200

|

200

|

220

|

250

|

320

|

|||||||

|

Pipe connection diameter(DN)

|

150

|

150

|

150

|

150

|

200

|

200

|

200

|

250

|

|||||||

|

Thermal Efficiency (%)

|

~95

|

|

|

|

|

|

|

|

|||||||

|

Size (m)

|

4.4x2.05

x2.45

|

5.1x2.2

x2.5

|

5.2x2.4

x3.0

|

5.83x2.94

x3.1

|

6.1x3.02

x3.2

|

7.0x2.63

x3.2

|

7.6x3.1

x3.2

|

8.3x3.2

x3.4

|

|||||||

|

Weight (T)

|

10

|

11.5

|

12.5

|

18.5

|

19.5

|

22

|

26

|

30

|

|||||||

|

MODEL

|

YY(Q)W- 7000Y(Q)

|

YY(Q)W- 8200Y(Q)

|

YY(Q)W- 9400Y(Q)

|

YY(Q)W- 10500Y(Q)

|

YY(Q)W- 12000Y(Q)

|

YY(Q)W- 14000Y(Q)

|

YY(Q)W- 18000Y(Q)

|

YY(Q)W- 23500Y(Q)

|

|||||||

|

Rated power(KW)

|

7000

|

8200

|

9400

|

10500

|

12000

|

14000

|

18000

|

23500

|

|||||||

|

Design pressure(Mpa)

|

0.9

|

|

|

|

|

|

|

|

|||||||

|

Rated working pressure(Mpa)

|

0.8

|

|

|

|

|

|

|

|

|||||||

|

Highest working temperature(℃)

|

320

|

|

|

|

|

|

|

|

|||||||

|

Furnace oil volume(m3/h)

|

9.1

|

10.5

|

12

|

14

|

16

|

18

|

24

|

32

|

|||||||

|

Circulation oil

volume(m3/h) |

375

|

400

|

520

|

550

|

600

|

680

|

1000

|

1200

|

|||||||

|

Pipe connection diameter(DN)

|

250

|

250

|

300

|

300

|

300

|

350

|

400

|

400

|

|||||||

|

Thermal Efficiency (%)

|

~95

|

|

|

|

|

|

|

|

|||||||

|

Size (m)

|

9.24x3.9

x3.5

|

5.1x2.2

x2.5

|

5.2x2.4

x3.0

|

5.83x2.94

x3.1

|

6.1x3.02

x3.2

|

7.0x2.63

x3.2

|

7.6x3.1

x3.2

|

8.3x3.2

x3.4

|

|||||||

|

Weight (T)

|

42.5

|

11.5

|

12.5

|

18.5

|

19.5

|

22

|

26

|

35

|

|||||||

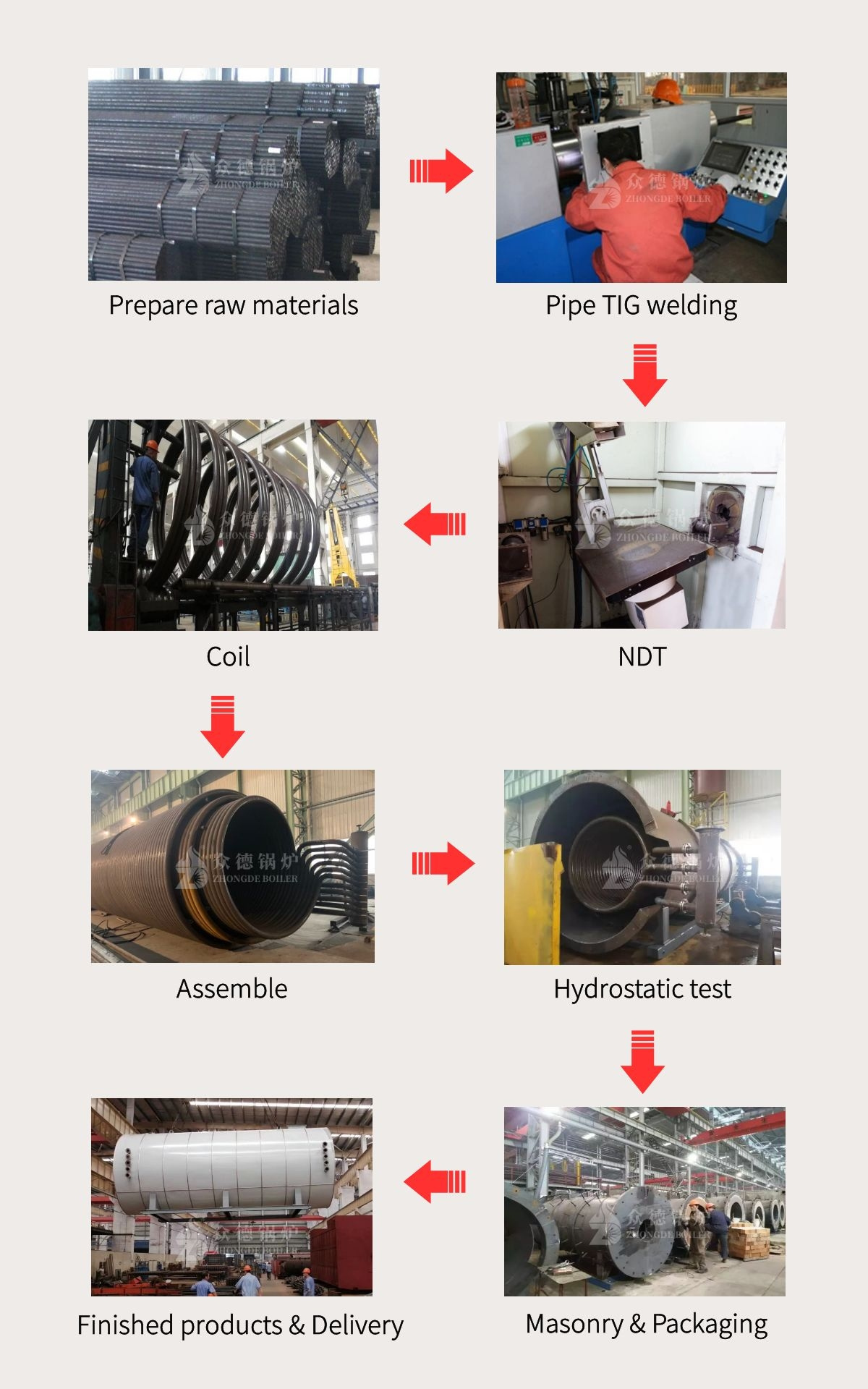

Product manufacturing process

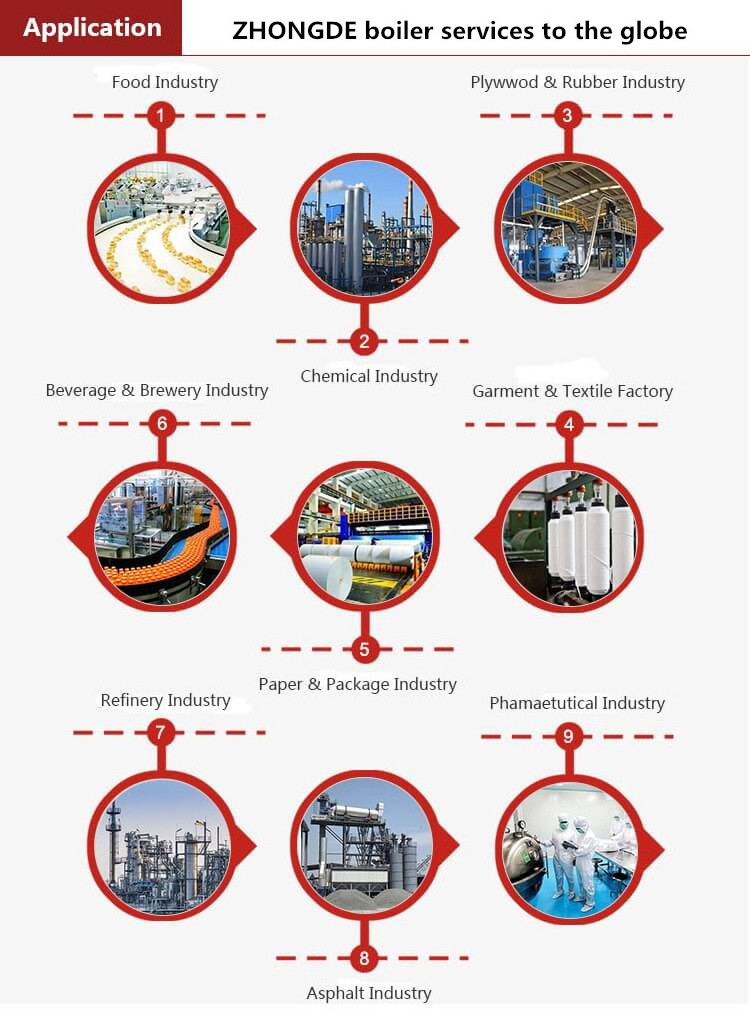

Application & Boiler case

Applicable industry

Chemical industry, grease, petrochemical, textile, printing and dyeing, plastics, rubber, fiber, carbon, construction, cement, asphalt, metal, coating, wood processing, papermaking and printing, atomic energy industry, etc.

6 MKcal Heat transfer oil boiler

Fuel:

Gas

User’s site:

Malaysia

Capacity: 7000KW

Application: Packing industry

4 MKcal Heat transfer oil boiler

Fuel: Gas

User’s site:

Indonesia

Capacity: 4700KW

Application:

Synthetic fiber industry

1.8 MKcal Heat transfer oil boiler

Fuel:

Gas

User’s site:

Vietnam

Capacity: 2100KW

Application: Rubber industry

0.6 MKcal Heat transfer oil boiler

Fuel: Oil

User’s site: Thailand

Capacity: 700KW

Application:

Asphalt mixing

Hot Searches