- Product Details

- {{item.text}}

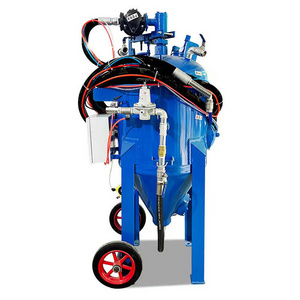

Quick Details

-

Weight (KG):

-

600

-

Product name:

-

abrasive blast machine

-

Model:

-

KPBM1560

-

Volume:

-

0.3cbm

-

Diameter:

-

600mm

-

Height:

-

1450mm

-

Working pressure:

-

0.3-0.7bar

-

Function:

-

Clean Rust Dust Oil

-

Power Supply:

-

Air Powered

-

Application:

-

Abrasive Blast Rust Cleaning

Quick Details

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Shliangshi

-

Marketing Type:

-

Hot Product 2022

-

Weight (KG):

-

600

-

Product name:

-

abrasive blast machine

-

Model:

-

KPBM1560

-

Volume:

-

0.3cbm

-

Diameter:

-

600mm

-

Height:

-

1450mm

-

Working pressure:

-

0.3-0.7bar

-

Function:

-

Clean Rust Dust Oil

-

Power Supply:

-

Air Powered

-

Application:

-

Abrasive Blast Rust Cleaning

Product Description

Pressure holding pneumatic remote control sandblaster

It consists of air inlet valve, pneumatic abrasive valve, control air duct and controller. When it works, the air inlet valve is opened and exhaust valve is closed, the pressure will be kept in the sandblast cylinder. You only need to push on the handle and the inlet valve and abrasive valve are opened at the same time, the sand and air can be blew out at the same time. When closed, the inlet valve and abrasive valve will be closed at the same time.

It consists of air inlet valve, pneumatic abrasive valve, control air duct and controller. When it works, the air inlet valve is opened and exhaust valve is closed, the pressure will be kept in the sandblast cylinder. You only need to push on the handle and the inlet valve and abrasive valve are opened at the same time, the sand and air can be blew out at the same time. When closed, the inlet valve and abrasive valve will be closed at the same time.

Pressure relief pneumatic remote control system

It consists of air inlet valve, exhaust valve, filter, control air duct and

controller. When it works, push down the handle, controlled air flow will reach the inlet valve and exhaust valve through another air duct to open the inlet valve and close the exhaust valve, the pressure inside the abrasive barrel rises and shot blasting starts. This type is widely applied in the container industry at present.

Manual double-chamber continuous sandblaster system

It consists of air inlet valve, exhaust valve, filter, control air duct and

controller. When it works, push down the handle, controlled air flow will reach the inlet valve and exhaust valve through another air duct to open the inlet valve and close the exhaust valve, the pressure inside the abrasive barrel rises and shot blasting starts. This type is widely applied in the container industry at present.

Manual double-chamber continuous sandblaster system

It consists of two chambers, when blasting, the lower chamber is holding pressure and the upper chamber is filling with sand. After filled with sand, the upper chamber is holding pressure, the closed valve of the lower chamber will drop automatically, the abrasive of the upper chamber will fall into the lower chamber, the two chambers can be either controlled by hand or automatically controlled by the timer, e.g. feed it every 5 minutes. The machine is characterized by continuous blasting, without interval time. It has very good effect on the places with special requirements which greately increase the working efficiency.

KPBMM1140 Portable Abrasive Blast Machine

t is characterized by

easy to move from one place to place for field construction. It applies especially to blast small batch of steel structure, and ironware, rehab of long pipeline and welded seam. At present, there is a large amount of this model under use on the projects such as

transfer of t he South-to-North Water Diversion and the West- East Gas Transmission

transfer of t he South-to-North Water Diversion and the West- East Gas Transmission

KPBMM1560 Portable manual controlled double chamber abrasive blast machine

It is one of the most commonly used machines in such enterprises such marine repair, anti-corrosion construction and steel structure.

It has features of simple operation, almost zero failure rate, economic and practical, thus warmly welcomed by customers.

KPBMR1760E electrical controlled double-chamber continuous abrasive blast machine

It is

suitable for continuous blasting operation. Continuous work will greatly reduce the blast cost and improve blast efficiency. According to double- chamber work principle, the machine can be separated relay type and material level

indicator type. Combining w ith the use of spiral conveyor and bucket elevator, it can carry out large-scale automated blasting recycling system

indicator type. Combining w ith the use of spiral conveyor and bucket elevator, it can carry out large-scale automated blasting recycling system

KPBSM1990 Stationary single chamber manual controlled abrasive blast machine

It can be either used as supporting equipment in large-sized sandblasting room for steel structure and piping fittings , or installed on m

obile construction vehicles.

It suits for long time intermittent operation. It is of good stability, convenient maintenance. It is available to choose double guns or more guns

KPBSRⅡ1990 single chamber double guns pneumatic controlled abrasive blast machine

It has two types, pressure-holding and pressure-reliving t. It can be either used as supporting equipment in large-sized sandblasting room for steel structure and piping fittings , or

installed on mobile construction vehicles. It suits for long time intermittent operation. It is of good stability, convenient

maintenance. It is available to choose double guns or more guns

installed on mobile construction vehicles. It suits for long time intermittent operation. It is of good stability, convenient

maintenance. It is available to choose double guns or more guns

KPBSRⅡ1990E Stationary electrical controlled abrasives blast machine with two guns

It is suitable for c

ontinuous blasting operation. Continuous work will greatly reduce the blast cost and improve blast efficiency. According to double- chamber work principle, the machine can be separated relay type and material level

indicator type. Combining with the use of spiral conveyor and bucket elevator, it can carry out large-scale automated blasting recycling system

indicator type. Combining with the use of spiral conveyor and bucket elevator, it can carry out large-scale automated blasting recycling system

Specification

|

KPBM high-efficient pressure type blast machine common models

|

|

|

|

|

|

|

|

|||||||

|

Description /size

|

KPBM(R)

1030 |

KPBM(R)

1140 |

KPBM(R)

1360 |

KPBM(R)

1560 |

KPBM(R)

1570 |

KPBM(R)

1760 |

KPBS(R)

1990 |

|||||||

|

Drum diameter(mm)

|

300

|

400

|

600

|

600

|

700

|

600

|

900

|

|||||||

|

Height(mm)

|

1000

|

1100

|

1300

|

1500

|

1500

|

1700

|

1900

|

|||||||

|

Volume(L)

|

80

|

100

|

300

|

300

|

300

|

400

|

100

|

|||||||

|

Weight(weight)

|

100

|

140

|

200

|

218

|

280

|

340

|

492

|

|||||||

|

Silo

|

1

|

1

|

1

|

1

|

1

|

2

|

1

|

|||||||

|

Nozzle

|

1

|

1

|

1

|

1

|

1

|

1-2

|

1-2

|

|||||||

|

Nozzle

|

M=portable S=fixed R=pneumatic control E=electrical control

|

|

|

|

|

|

|

|||||||

KPB series sandblaster instruction:KPBS[M]MRXX XXE K:Enterprise code, P: pressure feed, B: sandblaster, S:Stationary, M: mobile, R: pneumatic remote control, XX: drum height, XX: drum diameter, E: electrical remote control.

SHLIANGSHI series pressure feed type blast machine, depending on different place requirement, has more than 30 varieties in total. It can be generally divided into AC series and KPB series. Principle of operation of both series is almost the same, with the main difference lies in that the former features a little more sand feeding volume and the latter features convenient sand feeding.

SHLIANGSHI series pressure feed type blast machine, depending on different place requirement, has more than 30 varieties in total. It can be generally divided into AC series and KPB series. Principle of operation of both series is almost the same, with the main difference lies in that the former features a little more sand feeding volume and the latter features convenient sand feeding.

Application

Completed Projects

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Hot Searches