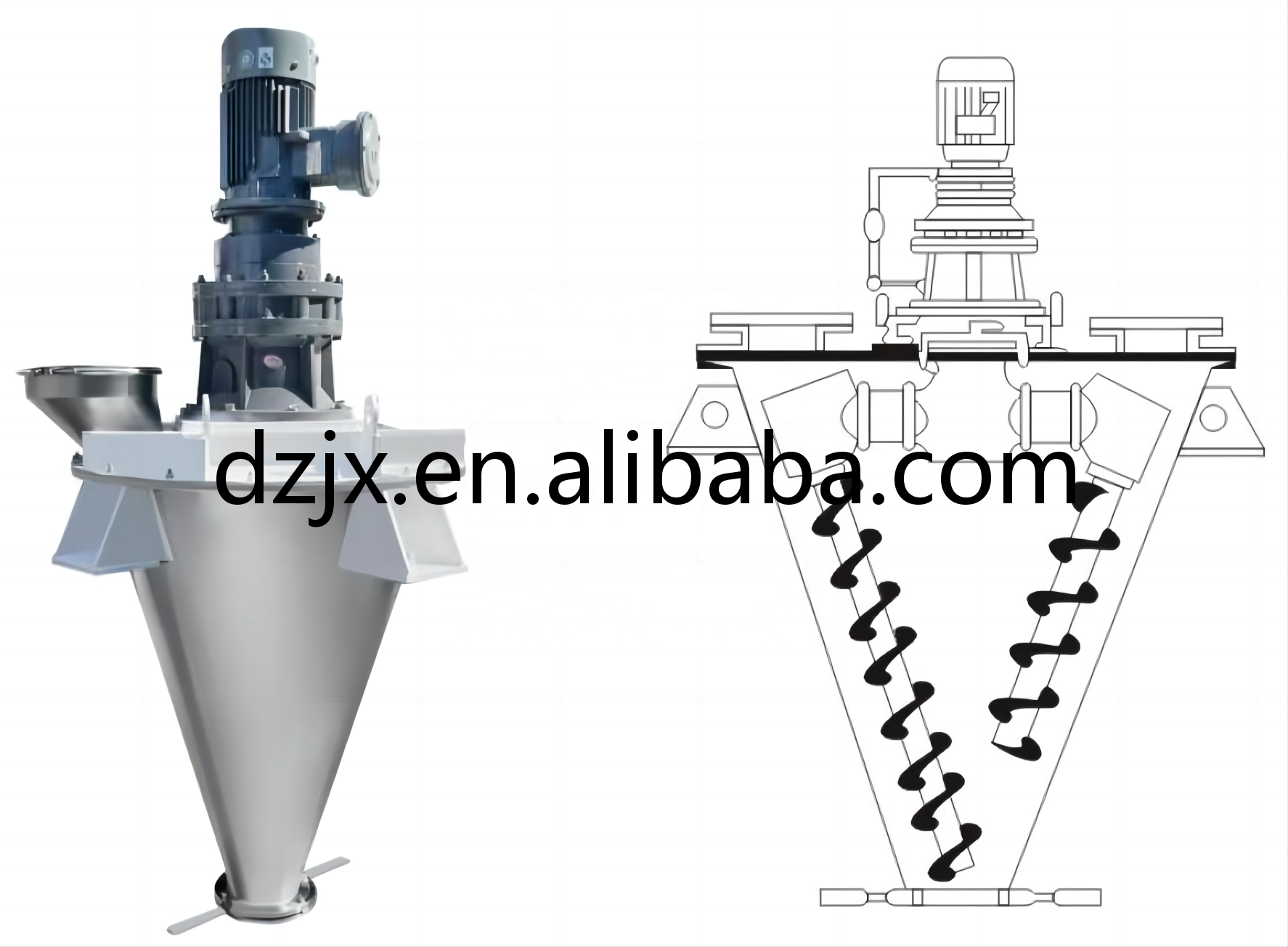

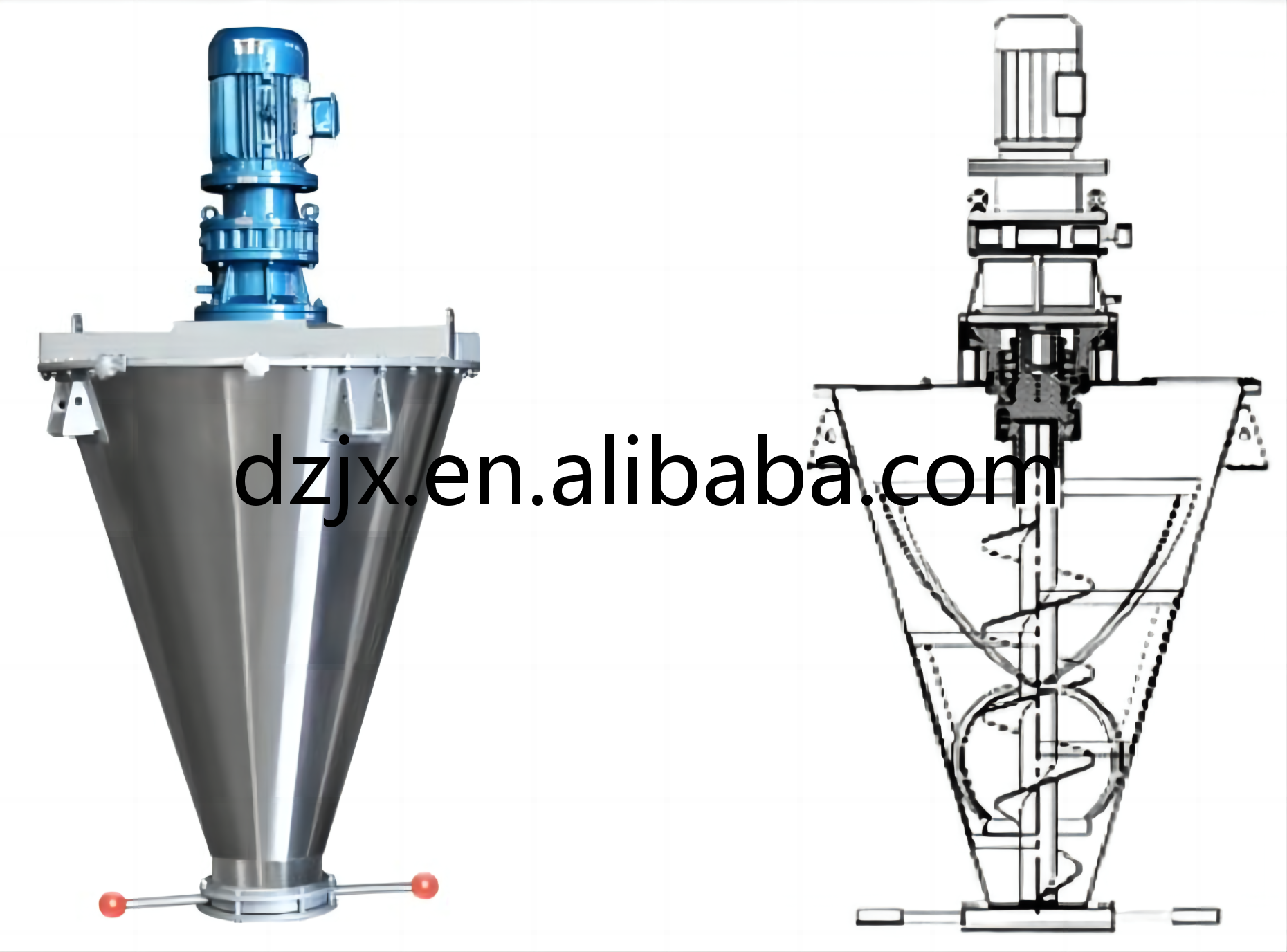

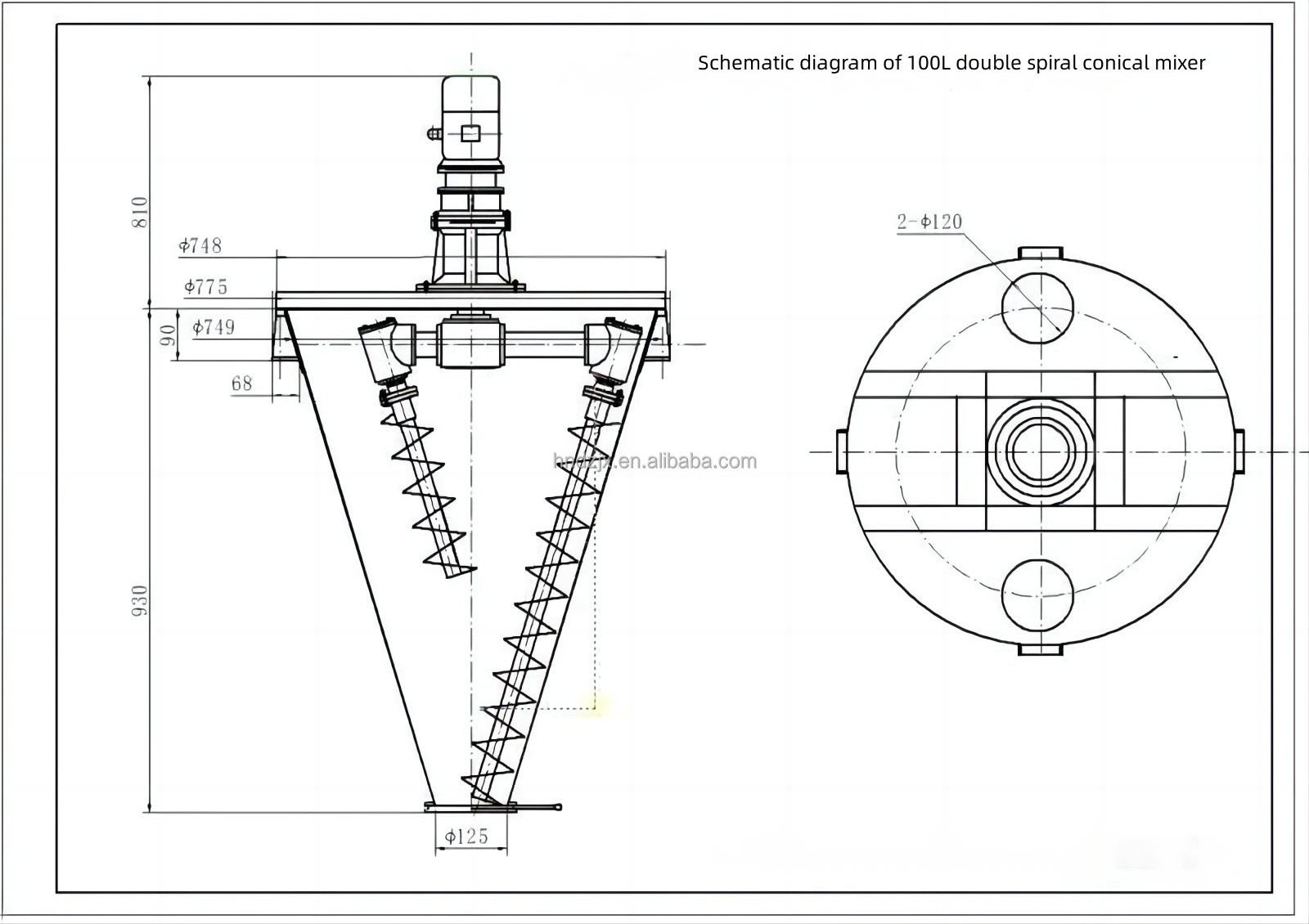

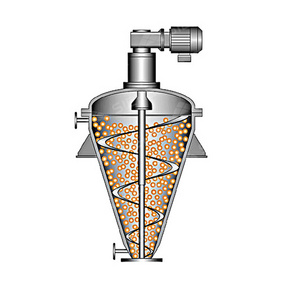

* The advantages of this machine are wide applicability, large volume, no residue discharge, and energy-saving.

* The conical mixer is suitable for

mixing powder with powder, particles with powder, powder with small amounts of liquid

, and is widely used in industries such as

chemical industry, dyes, pigments, pesticides, veterinary drugs, pharmaceuticals, plastics, and additives.

* This machine has a wide adaptability to mixtures,

does not overheat heat sensitive materials,

and can maintain the integrity of particles as much as possible for granular materials. It has good adaptability for the

mixing of coarse powder, fine powder, fiber or sheet materials.

* This machine can also produce various special forms such as

heating, cooling, positive pressure, vacuum, etc. according to user requirements

.