- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-1mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

zhongde

-

Voltage:

-

380V,50HZ Three-phase or you need

-

Dimension(L*W*H):

-

5500*800*1100

-

Weight:

-

3000 kg

-

After Warranty Service:

-

Field maintenance and repair service

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

Drywall track stud profile roll forming machine, structural steel

-

Raw material:

-

Steel, Galvanized Steel

-

Usage:

-

Building

-

Control system:

-

PLC(imported Brand)

-

Roller material:

-

Cr12

-

Shaft material:

-

45# Steel Outer Diameter: 40mm

-

Cutting blade material:

-

GCr12MoV Frequency Quenching

-

Number Of Rollers:

-

12-16

Quick Details

-

Type:

-

metal frame roll forming machine

-

Tile Type:

-

PI, PPGI, AL

-

Production Capacity:

-

40-50m/min

-

Rolling thinckness:

-

0.3-1mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

zhongde

-

Voltage:

-

380V,50HZ Three-phase or you need

-

Dimension(L*W*H):

-

5500*800*1100

-

Weight:

-

3000 kg

-

After Warranty Service:

-

Field maintenance and repair service

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

Drywall track stud profile roll forming machine, structural steel

-

Raw material:

-

Steel, Galvanized Steel

-

Usage:

-

Building

-

Control system:

-

PLC(imported Brand)

-

Roller material:

-

Cr12

-

Shaft material:

-

45# Steel Outer Diameter: 40mm

-

Cutting blade material:

-

GCr12MoV Frequency Quenching

-

Number Of Rollers:

-

12-16

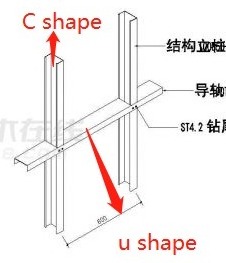

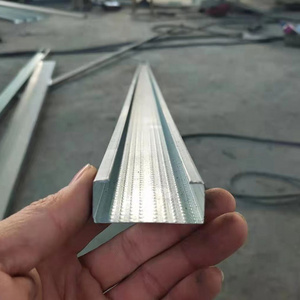

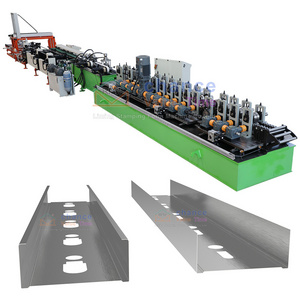

Drywall Light Gauge Steel Metal Stud Track Making Machine Steel Roof Truss Roll Forming Machine

Drywall Light Gauge Steel Metal Stud Track Making Machine Steel Roof Truss Roll Forming Machine, there have large keel, middle keel and small keel.

According to the weight, can be devided into heavy keel , middle keel, and light keel.

Our factory have many kinds of keel channel roll forming machine and can customized machine acording to your needed.

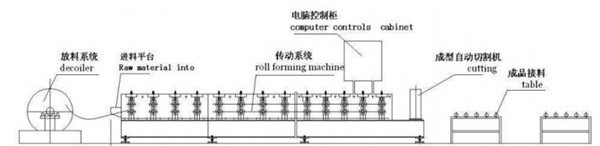

1. The Drywall Light Gauge Steel Metal Stud Track Making Machine Steel Roof Truss Roll Forming Machine work flow:

Uncoiling---main roll former---hydraulic cutting---product collect

2. Components of line:

|

No. |

Name |

Unit |

Qty |

|

1 |

Decoiler |

set |

1 |

|

2 |

Main Machine for roll forming |

set |

1 |

|

3 |

Control System(PLC) |

set |

1 |

|

4 |

Pressing System |

set |

1 |

|

5 |

Cutting System |

set |

1 |

|

6 |

Output Table |

set |

1 |

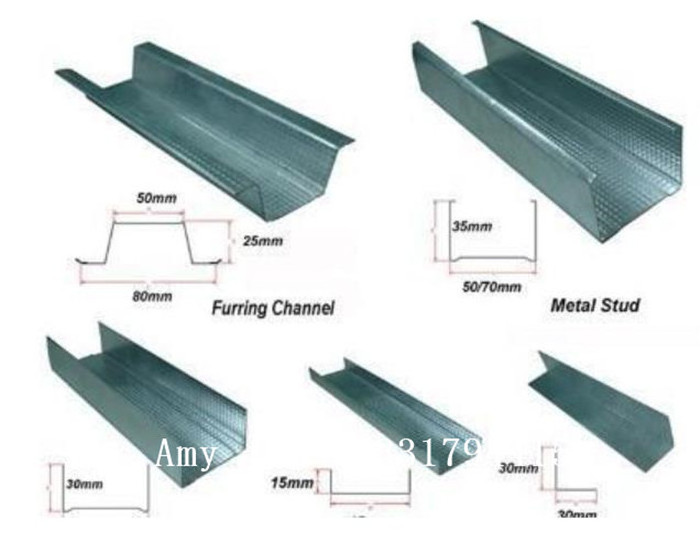

3. Sample Types

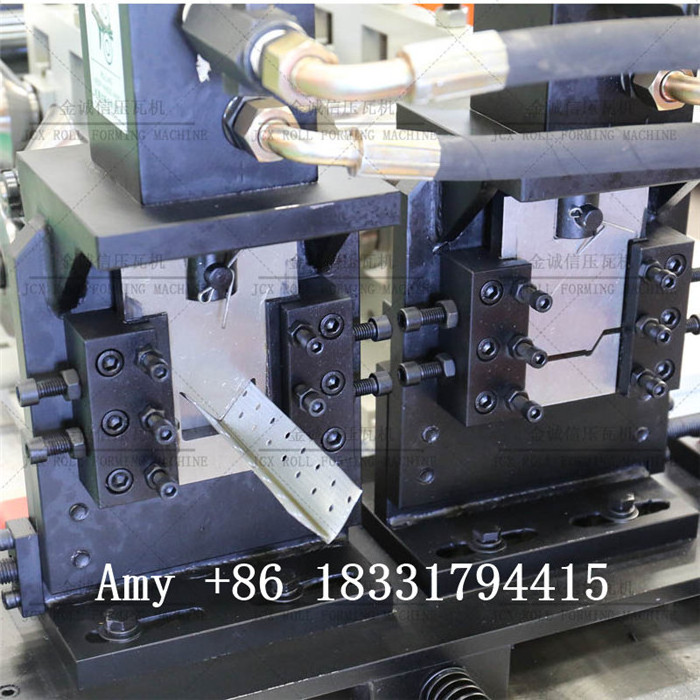

4. Details:

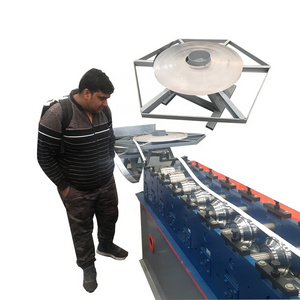

Decoiler System: (Drywall Light Gauge Steel Metal Stud Track Making Machine Steel Roof Truss Roll Forming Machine)

|

No : |

Decoiler System Main Parameter : |

|

|

1 |

Loading capacity |

1.5-3.0T |

|

2 |

Uncoiling width |

300-1000mm |

|

3 |

Inner diameter |

450-550mm |

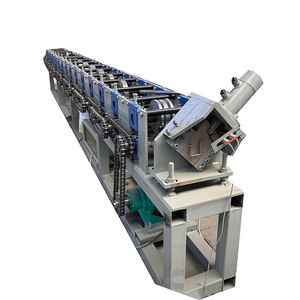

Roll Forming System: (Drywall Light Gauge Steel Metal Stud Track Making Machine Steel Roof Truss Roll Forming Machine)

|

No : |

Roll Forming System Main Parameter : |

|

|

1 |

Length of the main part |

about 3000*1000*400-8800*1500*1200 |

|

2 |

Weight of main part |

3-8 tons |

|

3 |

Working Speed |

40-45m/min |

|

4 |

Voltage |

380V/50HZ3Phase (as customer’s request) |

|

4 |

Roller fixer |

guide column |

|

5 |

Frame |

steel plate welded/ Memorial arch frame type |

|

6 |

Frame thickness |

20mm |

|

7 |

Drive mode |

gear |

|

8 |

Material of rollers |

GCr15MoV |

|

9 |

Material of shafts |

45# steel with tempering |

|

10 |

Diameter of shafts |

φ40mm |

|

11 |

Number of rollers |

10-16 rollers |

|

12 |

Main power |

3-8kw |

|

13 |

Servo Motor Power |

1.2KW |

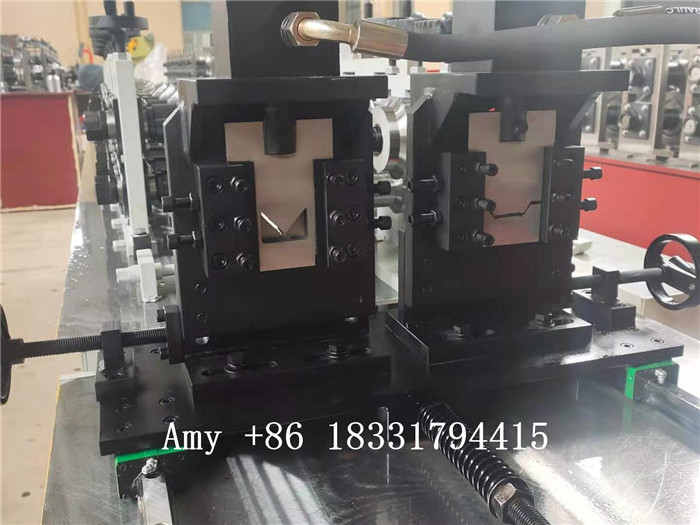

Automatic Cutting System:

Drywall Light Gauge Steel Metal Stud Track Making Machine Steel Roof Truss Roll Forming Machine

|

No : |

Cutting System Main Parameter : |

|

|

1 |

Material of blades |

Gcr12MoV quenched |

|

2 |

Cutting Type |

Non-Stop high speed cutting |

|

3 |

Drived by |

Servo motor |

|

4 |

Power supply |

hydraulic power |

|

5 |

Frame |

Pillar style with rack & pinion system |

|

6 |

Stroke switch |

non-contact photoelectric switch |

|

7 |

Hydraulic motor Power |

1.2 kw |

|

8 |

Hydraulic oil: |

46# |