- Product Details

- {{item.text}}

Quick Details

-

Feature:

-

Moisture Proof, Moisture proof

-

Place of Origin:

-

China shrink film

-

Brand Name:

-

KINGPOLY wrapping film

-

Model Number:

-

shrink film#230102-H4

-

Product name:

-

Centerfold Heat Activated Shrink Wrap

-

useage:

-

low temperatures to shrink and offers up to a 55% shrink rate

-

Thickness:

-

80Gauge 90Gauge 100Gauge 115Gauge150Gauge

-

Roll Width:

-

10mm-1800mm

-

Printing:

-

Customized Printed

-

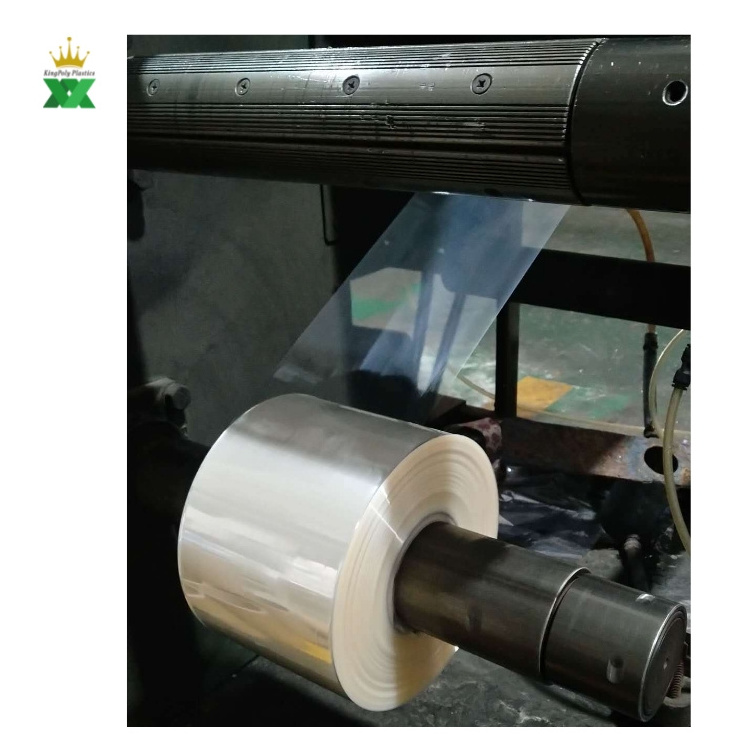

Raw material:

-

Heat Activated Shrink Film

-

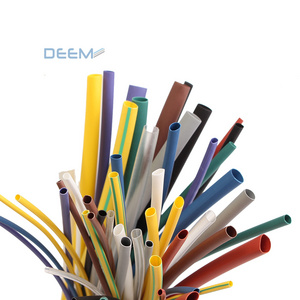

PVC shrink film type:

-

PVC tubular film,sleeve film,single wound film,center-folded

-

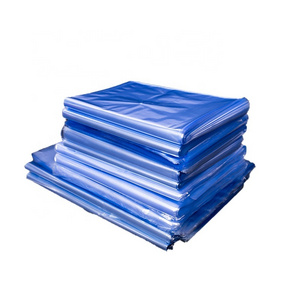

transparency:

-

transparent Blue film ,red, green

-

Keyword:

-

Pvc Shrink Film Heat Shrinkable Sleeves

Quick Details

-

Material:

-

PVC,POF,PE

-

Type:

-

Stretch Film

-

Usage:

-

Packaging Film,packaging film

-

Feature:

-

Moisture Proof, Moisture proof

-

Place of Origin:

-

China shrink film

-

Brand Name:

-

KINGPOLY wrapping film

-

Model Number:

-

shrink film#230102-H4

-

Product name:

-

Centerfold Heat Activated Shrink Wrap

-

useage:

-

low temperatures to shrink and offers up to a 55% shrink rate

-

Thickness:

-

80Gauge 90Gauge 100Gauge 115Gauge150Gauge

-

Roll Width:

-

10mm-1800mm

-

Printing:

-

Customized Printed

-

Raw material:

-

Heat Activated Shrink Film

-

PVC shrink film type:

-

PVC tubular film,sleeve film,single wound film,center-folded

-

transparency:

-

transparent Blue film ,red, green

-

Keyword:

-

Pvc Shrink Film Heat Shrinkable Sleeves

|

Width |

20 mm-1800mm |

Tensile strength |

In transverse direction ≥50 Mpa |

|

Thickness |

1 3 um- 10 0um |

In machine direction ≥45Mpa |

|

|

Shrinkage rate |

In transverse direction 5%-55% |

Breaking elongation |

In transverse direction ≥50% |

|

In machine direction 10%-55% |

In machine direction ≥70% |

||

|

Shrinkage temperature |

90°C-150°C |

Tearing strength |

In transverse direction ≥45KN/m |

|

Transparency |

≥95°C |

In machine direction ≥60KN/m |

|

|

Specific weight |

1.40g/cm3 |

|

|

How to Choose the Right Heat Shrink Machine

Selecting the best heat shrink machine involves considering several factors:

#01 Product Characteristics: Assess the size, shape, and heat sensitivity of your products. Certain machines are better suited for specific product types, such as delicate items or irregular shapes.

#02 Production Volume and Pace:

Consider your production volume. High-volume operations may benefit from faster, more automated machines like shrink tunnels, while smaller volumes might be better served by a more versatile machine.

#03 Energy Efficiency and Operational Costs:

Look for machines that offer good energy efficiency to reduce operational costs and align with eco-friendly practices.

#04 Space Requirements:

Consider the physical space available in your facility. Some machines have a larger footprint and may require more setup space.

Making the right choice will depend on balancing these factors with your business’s specific packaging requirements and operational constraints.

Knowing the product Length x Width x Height x Weight can be an excellent indicator for which shrink wrap type to use. See below for a brief description of shrink wrap type.

6" L x 6" W 80 Gauge Clear PVC Shrink Bags

11" L x 6" W 80 Gauge Clear PVC Shrink Bags

10" L x 7" W 80 Gauge Clear PVC Shrink Bags

12" L x 8" W 80 Gauge Clear PVC Shrink Bags

14" L x 9" W 80 Gauge Clear PVC Shrink Bags

16" L x 12" W 80 Gauge Clear PVC Shrink Bags

18" L x 16" W 100 Gauge Clear PVC Shrink Bags

18" L x 18" W 100 Gauge Clear PVC Shrink Bags

20" L x 20" W 100 Gauge Clear PVC Shrink Bags

22" L x 22" W 100 Gauge Clear PVC Shrink Bags

24" L x 24" W 100 Gauge Clear PVC Shrink Bags

28" L x 26" W 100 Gauge Clear PVC Shrink Bags

30" L x 30" W 100 Gauge Clear PVC Shrink Bags

36" L x 36" W 100 Gauge Clear PVC Shrink Bags