- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

3500*3200*2800mm

-

Year:

-

2021

-

Power (kW):

-

268 kW

-

Weight (KG):

-

90000 KG

-

Applicable Industries:

-

Tire Recycle

-

End product:

-

tire rubber powder

-

Marketing Type:

-

Ordinary Product

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

YUXI

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

3500*3200*2800mm

-

Year:

-

2021

-

Power (kW):

-

268 kW

-

Weight (KG):

-

90000 KG

-

Applicable Industries:

-

Tire Recycle

-

End product:

-

tire rubber powder

-

Marketing Type:

-

Ordinary Product

Products Description

Introduction of Tire Recycling Machine

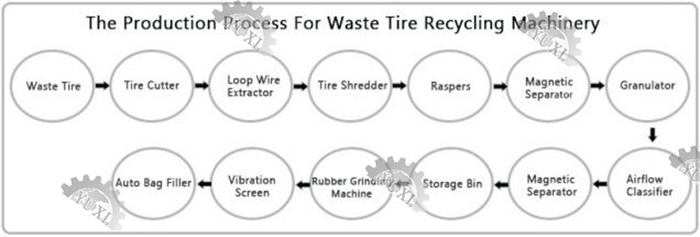

The tire recycling equipment is mainly used to produce waste rubber tires, steel wire, rubber powder, fiber and other building raw materials. The whole tyre recycling production line includes double-shaft shredder, wire drawing machine, steel wire separator, magnetic separator, Grinders, conveyors, fiber separators, control cabinets and other machines. High recovery rate of the entire production line, high degree of automation, saving manpower

Working process

Application Scopes

The rubber granules produced can be used as raw materials for rubber flooring.

Can also be used to build rubber runways and artificial grass

Final products

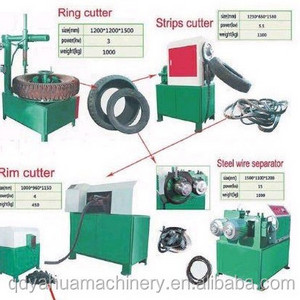

Details Images

1.

Conveyor

-Transport the tire to the shredder;

2.

Double shaft shredder

---Shears the tire into 5-10 cm blocks;

3.

Recirculation system

---To control the size of shreds going to the raspers;

4.

Raspers

-Reduce the shreds into 15-20 mm chips and liberates steel from the rubber;

5.

Over belt magnet

--Separation of liberated steel from the rubber chips;

6.

Vibratory feeder

--Transports the rubber chips;

7.

Granulator

--Size reduction of the chips to 1-4 mm granules and liberates the textile fraction to air flow separation.

8.

Vibratory screen

-Sorts the granules by size and removes the majority of textile;

9.

Classifer

-Removal of remaining textile; Drum magnet-Removal of remaining steel fines;

10.

Central de-dusting unit

--Remove dust and fines from the system and filter the air before returning it to the atmosphere.

Project case

Our tire production line is sold to Romania, Chile, Saudi Arabia and other countries, we will go to the site to help customers install the machine.

Product Paramenters

|

Capacity

|

500-10000kg/h

|

|

Scope of application

|

Diameter of the tire:400-3000mm

|

|

Output size

|

5-100 mesh,Can be Customized

|

|

Complete separation

|

The rubber Crumbs,Steel and Fibre can be separated automatically.

|

|

Equipment required area

|

Equipment required area

|

|

Characteristic of blade

|

Characteristic of blade

|

|

Dimension(L*W*H):

|

3500*3200*2800mm

|

|

Weight:

|

35-40 Ton

|

Product packaging

Hot Searches