- Product Details

- {{item.text}}

Quick Details

-

Application:

-

for insulating glass

-

Design Style:

-

Contemporary

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

CHICO

-

Model Number:

-

PVB FILM 1.14MM

-

Type:

-

PVB FILM FOR GLASS

-

Material:

-

Polyvinyl Butyral

-

Use for:

-

Industrial, Decoration, Curtain Wall, Building

-

Color:

-

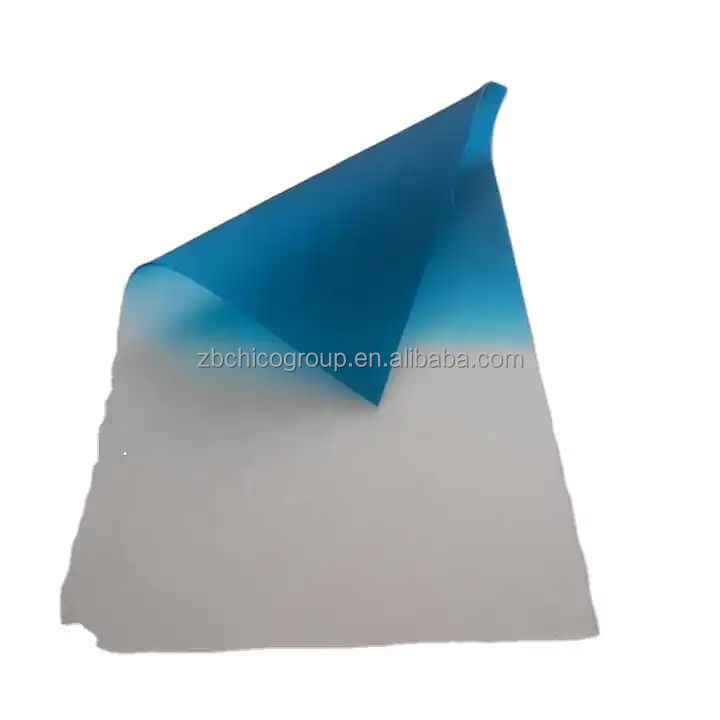

Clear,White,Black,Colourful

-

Specification:

-

0.38/0.76/1.14/1.52MM

-

Surface Treatment:

-

Top Layer Surface, No Scratches, Creases, Uniform

-

Processing Service:

-

Cutting

-

Plastic Modling Type:

-

Extruding

-

Structure:

-

soft

-

Visible Light Transmittance:

-

MIN 80%

-

Certificate:

-

ISO9001

Quick Details

-

Warranty:

-

1 Year

-

After-sale Service:

-

Online technical support, Onsite Training, Onsite Inspection, Free spare parts

-

Project Solution Capability:

-

graphic design, total solution for projects, Cross Categories Consolidation

-

Application:

-

for insulating glass

-

Design Style:

-

Contemporary

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

CHICO

-

Model Number:

-

PVB FILM 1.14MM

-

Type:

-

PVB FILM FOR GLASS

-

Material:

-

Polyvinyl Butyral

-

Use for:

-

Industrial, Decoration, Curtain Wall, Building

-

Color:

-

Clear,White,Black,Colourful

-

Specification:

-

0.38/0.76/1.14/1.52MM

-

Surface Treatment:

-

Top Layer Surface, No Scratches, Creases, Uniform

-

Processing Service:

-

Cutting

-

Plastic Modling Type:

-

Extruding

-

Structure:

-

soft

-

Visible Light Transmittance:

-

MIN 80%

-

Certificate:

-

ISO9001

Product Description

Product Details

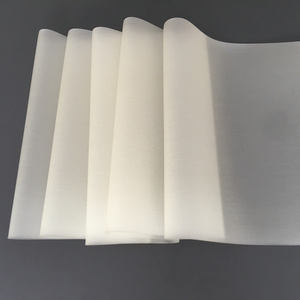

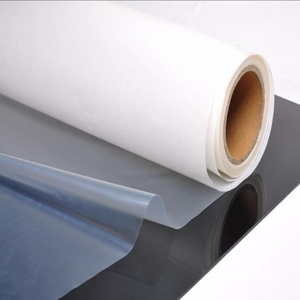

PVB interlayer is a translucent film, a polymer material made of polyvinyl butyral resin plasticized and extruded with a plasticizer. The appearance is a translucent film with no impurities, a smooth surface, a certain degree of roughness and good softness, good adhesion to inorganic glass, transparency, heat resistance, cold resistance, moisture resistance, and high mechanical strength. It is Currently one of the best adhesive materials in the world for manufacturing laminated and safety glass. Its advantages are safety, anti-theft, explosion-proof, sound insulation and energy saving properties.

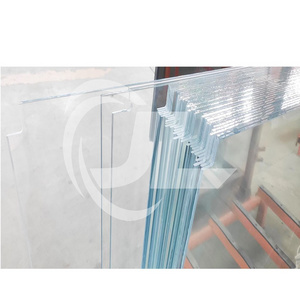

PVB interlayer is mainly used for laminated glass, which is a special glass made by sandwiching a layer of PVB film between two pieces of glass, compounding at high pressure and heating. JD-PVB laminated glass is widely used in construction, automobile and other industries due to its multiple functions such as safety, heat preservation, noise control and ultraviolet isolation. PVB interlayer films produced with special formulas are also widely used in aerospace, military and high-tech industries, such as aircraft, spacecraft, military instruments, solar battery boxes, solar receivers, etc.

Application areas:

1: Automotive field: Maintenance film and coating technology for car bodies, windows, rearview mirrors, front windshields, interior environment, etc.

2: Construction field: functional membrane and coating technology for roofs, interior and exterior walls, glass curtain walls, decorative materials, indoor environments, etc.

3: Textile field: functional finishing and masterbatch drawing technol ogy for clothing, carpets, curtains, towels, bedding, etc.

4: Electronic information field: functional coating technologies such as transparent conductive anti-static infrared protection for electronic components and production environments

5: Public health field: antibacterial and mildew-proof technology for public environmental facilities such as hospitals and schools

6: Coating field: surface insulation, antibacterial, hardening and other coating technologies and coating additive technologies for glass, plastic and other substrates

7: Engineering plastics field: functional plastic particles for films and plates and film injection molding technology

8: Environmental protection field: degradable technology of industrial glue and film

Specification

|

Roughness

|

15-55mic

|

|

Moisture content

|

0.35-0.55%

|

|

Thermal shrinkage

|

≤12%

|

|

Hit value

|

≥7

|

|

Visible light transmittance

|

50-80%

|

|

haze

|

<0.6%

|

|

tensile strength

|

≥20MPA

|

|

Tensile elongation

|

≥200%

|

|

Tensile elongation

|

≤10

|

Advantage:

Safety, Sound Insulation, Anti-Ultraviolet, and Decorative Features of Laminated Glass

Introducing the exceptional features of our laminated glass, brought to you by Zibo Chico International Co., Ltd.

Safety

When damaged, our laminated glass ensures the glass fragments do not fall off, maintaining integrity and avoiding breakdown. The PVB film enhances the elasticity of the glass, slowing down external impact and protecting human body safety. Additionally, specific combinations can transform our laminated glass into bulletproof glass or high-strength explosion-proof glass.

Sound Insulation

Experience the noise reduction effect of our laminated glass due to the sound-absorbing properties of the PVB film.

Anti-Ultraviolet

Our laminated glass blocks harmful ultraviolet rays. The PVB film reduces 99% of ultraviolet radiation, providing protection

against sunburn and skin cancer, even with prolonged exposure to the sun. It also prevents indoor furniture made of PVB laminated glass from discoloration.

Decorative

Choose from a variety of colors of our PVB film, allowing you to create rich decorative effects when used with paint and ceramics. Discover the exceptional quality and benefits of our laminated glass, designed to meet your safety, sound insulation, UV protection, and decorative needs. Contact Zibo Chico International Co., Ltd. for more information.

Introducing the exceptional features of our laminated glass, brought to you by Zibo Chico International Co., Ltd.

Safety

When damaged, our laminated glass ensures the glass fragments do not fall off, maintaining integrity and avoiding breakdown. The PVB film enhances the elasticity of the glass, slowing down external impact and protecting human body safety. Additionally, specific combinations can transform our laminated glass into bulletproof glass or high-strength explosion-proof glass.

Sound Insulation

Experience the noise reduction effect of our laminated glass due to the sound-absorbing properties of the PVB film.

Anti-Ultraviolet

Our laminated glass blocks harmful ultraviolet rays. The PVB film reduces 99% of ultraviolet radiation, providing protection

against sunburn and skin cancer, even with prolonged exposure to the sun. It also prevents indoor furniture made of PVB laminated glass from discoloration.

Decorative

Choose from a variety of colors of our PVB film, allowing you to create rich decorative effects when used with paint and ceramics. Discover the exceptional quality and benefits of our laminated glass, designed to meet your safety, sound insulation, UV protection, and decorative needs. Contact Zibo Chico International Co., Ltd. for more information.

Packing & Delivery

Packing and shipping:

1).Marks: it should include the product name, specifications, lot number, production date, expiration date, plant address and the brand name.

2).The package: the pvb film is insulated with PE film, cased into an aluminum foil bag, then vacuum sealed, and lastly into wood box or card drum. There should be quality certificate, packing list in the package. The marks of moisture proof, shock proof and sunlight proof should be labeled.

3).Transportation:there should be no direct sunlight, drench, and violent shaking during the transportation.

4).Storage: the product should be stocked in clean warehouse and normal temperature. It is forbidden to leave it under direct sunlight. As for the broken or opened package, they should be stocked under temperature of 20°C±5°C and in relative humidity of 20%-40%.

5).Shelf life: under normal atmospheric temperature, if well-packaged, the shelf life can be 2 years.

1).Marks: it should include the product name, specifications, lot number, production date, expiration date, plant address and the brand name.

2).The package: the pvb film is insulated with PE film, cased into an aluminum foil bag, then vacuum sealed, and lastly into wood box or card drum. There should be quality certificate, packing list in the package. The marks of moisture proof, shock proof and sunlight proof should be labeled.

3).Transportation:there should be no direct sunlight, drench, and violent shaking during the transportation.

4).Storage: the product should be stocked in clean warehouse and normal temperature. It is forbidden to leave it under direct sunlight. As for the broken or opened package, they should be stocked under temperature of 20°C±5°C and in relative humidity of 20%-40%.

5).Shelf life: under normal atmospheric temperature, if well-packaged, the shelf life can be 2 years.

Hot Searches