High quality HRE alloy resistance wire,Excellent temperature uniformity;

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V, 380V

-

Weight (T):

-

0.5 T

-

Power (kW):

-

5kw

-

Max temperature:

-

1700C

-

Working temperature:

-

1600C

-

Heating Element:

-

Mosi2

-

Thermocouple:

-

B Type

-

Power:

-

15kw

-

Temperature control:

-

PID Auto Control

-

Heating Rate:

-

0-20C/min

-

Certification:

-

CE ISO TUV

-

Chamber material:

-

Ceramic Fiber Chamber

Quick Details

-

Place of Origin:

-

Henan, China

-

Marketing Type:

-

Hot Product 2022

-

Brand Name:

-

SAFTherm

-

Voltage:

-

220V, 380V

-

Weight (T):

-

0.5 T

-

Power (kW):

-

5kw

-

Max temperature:

-

1700C

-

Working temperature:

-

1600C

-

Heating Element:

-

Mosi2

-

Thermocouple:

-

B Type

-

Power:

-

15kw

-

Temperature control:

-

PID Auto Control

-

Heating Rate:

-

0-20C/min

-

Certification:

-

CE ISO TUV

-

Chamber material:

-

Ceramic Fiber Chamber

Product Application

1700°C atmosphere furnace mainly provides high temperature heat treatment environment for industrial, research institutes,factories and other industrial laboratories, and is applied to new materials such as metal materials, ceramic materials, nano materials, and semiconductor materials.

|

Model

|

STQ-8-17

|

STQ-20-17

|

STQ-36-17

|

STQ-64-17

|

|||

|

Chamber Size mm(W*D*H)

|

200x200x200

|

250x320x250

|

300x400x300

|

400x400x400

|

|||

|

Power supply

|

220V/5KW

|

380V/7KW

|

380V/13KW

|

380V/18KW

|

|||

|

Type

|

Benchtop

Front-loading |

|

|

|

|||

|

Usage

|

General purpose furnace ideal for general laboratory uses—gravimetric analysis, sintering, quantitative analysis and heat

treatment |

|

|

|

|||

|

Furnace structure

|

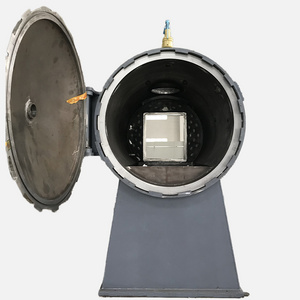

1700 Degree Heat Treatment Vacuum Argon Atmosphere Sintering Furnace For Ceramic Pottery Kiln

1. The furnace is consist of heating system, gas system, vacuum system 2. chamber is consist of insulation material and heating elements and atmosphere boxes 3. Temperature controller is consist of PID temp. controller, control elements and thermocouple 4. Integrated the furnace body and the temperature controller in one, the furnace is fixed on the temperature controller |

|

|

|

|||

|

Rated Max. temperature

|

500℃

|

1700℃

|

|

|

|||

|

Continuous Working temperature

|

500℃

|

1600℃

|

|

|

|||

|

Heating Rate

|

≤15℃/min (suggest 10℃/min for longer life using of furnace)

|

|

|

|

|||

|

Heating Element

|

With the features of small volume, low energy consumption and light weight, the mini furnace is convenient for every person hold

one set in the laboratory. It use SIC Rod as heating element, adopted carbon steel shell structure and intelligent temperature control system |

|

|

|

|||

|

Chamber material

|

1. Adopt high quality alumina polycrystalline fiber, which used Japanese technology (vac-sorb forming alumina polycrystalline

fiber) with good insulation and durability properties 2. High quality 1800 degree fiber alumina as refractory lining, pure white color 3. Ceramic fiber insulation for fast heat-up and reduced energy consumption—rise time to 1100°>C takes only 50 minutes 4. Vertical heating elements evenly distributes on two sides of the chamber which give an ideal temperature uniformity |

|

|

|

|||

|

Temp. Uniformity

|

±5°C

|

|

|

|

|||

|

Thermocouple

|

B type

|

|

|

|

|||

|

Temperature Controller

|

1. Control system integrated in the furnace base, Defined application within the constraints of the operating instructions

2. Furnace temperature controller utilizes Inteligient PID 32 segments programs 3. Feature single setpoint digital control, LED display of actual temperature VS set point 4. A high-precision digital microprocessor controller fitted with self-tuning and manual PID settings makes temperature and other parameters easy to control 5. Temperature controller Precision ±1℃ |

|

|

|

|||

|

Electronic component

|

SCHNEIDER maker air switch, buttons, solid-state relay, A.C contactor etc.

|

|

|

|

|||

|

Furnace Shell

|

1. High quality cold-rolled steel sheets CNC processing

2. Environmental electrostatic plastic-spraying on surface after deoiling, derusting, phosphating etc. nine processes 3. Energy efficient insulation keeps exterior safe to touch |

|

|

|

|||

|

Safety Precautions

|

1. Overheating & Broken thermocouple protection

2. Leakage circuit breaker 3. Automatic power off when furnace door opens (optional function) 4. Over-temperature protection and alarm allow for operation without attendant(s) 5. Microprocessor-based PID control with self-tuning capability to prevent overshooting of set temperature |

|

|

|

|||

|

Supply Scope

|

1. One furnace body

2. One set of temperature controller system 3. Three-meter power line 4. One thermocouple 5. One pair of crucible stongs 6. One pair of high temperature furnace gloves 7. An instruction book |

|

|

|

|||

|

Optional Accessories

|

1. Alumina crucibles

2. paperless recorder 3. exhaust chimney |

|

|

|

|||

|

Certification

|

ISO9001 CE SGS

|

|

|

|

|||

|

Warranty

|

One year limited manufacturer's warranty (Consumable parts such as processing tubes, O-rings and heating elements are not covered

by the warranty, please order replacements at related products respectively |

|

|

|

|||

Furnace Chamber Material

High grade alumina ceramicaterials as chamber materials with good temperature uniformity inchamber

Double furnace doors

Inner door block the fire and outer door is sealed with flanges.High temperature PTFE gasket is installed on the outer furnace door to ensure the reliable sealing of the furnace.

Rotary vane vacuum pump

The fumace body is equipped with an air oulet which used for extracting air and get vacuum environment, Vacuum degree ≤ 20000Pa.

(Optional Accessories)

M

ain Features

High standard, high quality

Heating Element

Temp Controller

It can be programmed with 30 sections, and RS485 communication interface and communication software can be selected to realize remote control and data recording of the furnace;

Gas Flow Meter

This gas meter is connected to hose to measure unidirectional gas flow;

Air extraction port

Air inlet, vacuum pump interface, air outlet, high pressure and high temperature stainless steel valve, improving air tightness;

Industrial chiller

(Optional Accessories)

(Optional Accessories)

To cool the furnace body during heat processing for safe and prolonged lifetime;

1.Temp. max 1700 °C

2.Fiber-insulated chamber for maximum temperature stability and uniformity

3.Powerful MoSi2 rod heating elements disctributed evenly on two sides

4.Dual Stainless Steel Design (New Design)

5.Programmable Digital PID Temperature Controller

6.Long life type B thermocouple

7.CE certified, standard

2.Fiber-insulated chamber for maximum temperature stability and uniformity

3.Powerful MoSi2 rod heating elements disctributed evenly on two sides

4.Dual Stainless Steel Design (New Design)

5.Programmable Digital PID Temperature Controller

6.Long life type B thermocouple

7.CE certified, standard

Henan Sante Furnace Technology Co., Ltd. is a high-tech enterprise located in Luoyang area of Henan﹒China Free Trade Zone.SAFTHERM products cover 1000℃/1200℃/1300℃/1400℃/1600℃/1700℃/1800℃ Box furnace, Tube furnace, Vacuum furnace, High Temperature Furnace, 2000℃ Ultra-High Temperature Furnace, Dental furnace, Industrial chamber furnace, elevator furnace, Intelligent mobile car bottom furnace, Smelting furnace and so on.

Henan Sante Furnace Technology Co., Ltd.

Email:sales@saftherm.com

Hot Searches