- Product Details

- {{item.text}}

Quick Details

-

Power:

-

105kw, 160kw

-

Weight:

-

3500 KG

-

Dimension(L*W*H):

-

2m/3m/as customer's requirement

-

Year:

-

2024

-

Product name:

-

Snack food extruder

-

Application:

-

Snack Food Processing Machine

-

Material:

-

304 Stainless Steel

-

Power Source:

-

Electric Gas Diesel

-

Certification:

-

ISO CE

-

Raw material:

-

Grain Powder

-

Capacity:

-

300-500kg/h

-

Final product:

-

Snack Pellets/Chips/Sticks

-

Temperature:

-

50-300 Degree

-

After-sales Service Provided:

-

Field Installation

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

SAIXIN

-

Voltage:

-

380V, customize

-

Power:

-

105kw, 160kw

-

Weight:

-

3500 KG

-

Dimension(L*W*H):

-

2m/3m/as customer's requirement

-

Year:

-

2024

-

Product name:

-

Snack food extruder

-

Application:

-

Snack Food Processing Machine

-

Material:

-

304 Stainless Steel

-

Power Source:

-

Electric Gas Diesel

-

Certification:

-

ISO CE

-

Raw material:

-

Grain Powder

-

Capacity:

-

300-500kg/h

-

Final product:

-

Snack Pellets/Chips/Sticks

-

Temperature:

-

50-300 Degree

-

After-sales Service Provided:

-

Field Installation

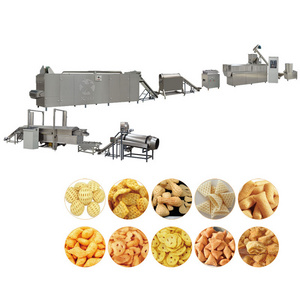

Products Description

Raw Materials

Our extruder integrates multiple processes and is a compact and cost-effective unit with a wide range of operating parameters.

Wide range of uses, including: post-extrusion filling, cutting or forming equipment, easy switching of functional equipment, enabling the production of multiple products in one extrusion line with minimal changeover time.

Single Screw Extruder

The single-screw extruder consists of a control cabinet, a transmission system, a feeding system, an extrusion system, a heating system, a cooling system, and a rotary cutting system.

It can produce snacks in various shapes such as macaroni, shrimp crackers, shrimp crackers,round/square tube/shell spiral, etc.

Double Screw Extruder

Applications

Our Advantages

1. PLC touch screen for Centralized,accurate,convenient control.

2. Fully automatic control system for heating and circulated cooling accurately.

3. Direct transmission of motor and distribution box reduces energy loss.

4. Imported bearing group with higher bearing capacity.

5. Equip with water injecting device on barrel to meet require of various material and quality.

6. High-speed tool steel with hardness HRC≥62 to lice a longer life.

7. Modular combination of screws at will to meet require of different raw material.

8. Suspension type rotary cutter with bearing adjusting device to ensure quick,safe and accurate.

2. Fully automatic control system for heating and circulated cooling accurately.

3. Direct transmission of motor and distribution box reduces energy loss.

4. Imported bearing group with higher bearing capacity.

5. Equip with water injecting device on barrel to meet require of various material and quality.

6. High-speed tool steel with hardness HRC≥62 to lice a longer life.

7. Modular combination of screws at will to meet require of different raw material.

8. Suspension type rotary cutter with bearing adjusting device to ensure quick,safe and accurate.

Specification

Our products can be customize

d

, tell us the specifications you need and our sales staff will provide you with the equipment and machine specifications that suit you best.

Single Screw Exdruter

|

Model

|

SX3000-55/65

|

SX3000-80/100

|

SX3000-130/150

|

|

Motor power

|

7.5/15kw

|

22/30kw

|

37/45/55kw

|

|

Output

|

60-100kg/h

|

80-120kg/h

|

200-250kg/h

|

Double Screw Extruder

|

Model

|

DS65

|

DZ70

|

DZ80

|

DZ100

|

DZ110

|

|

Power supply voltage

|

380V/50HZ

|

380V/50HZ

|

380V/50HZ

|

380V/50HZ

|

380V/50HZ

|

|

Outline size

|

3.5*1*1.2m

|

3.8*1*3m

|

4x1.2x3.2 m

|

5.7×1.3×1.5m

|

5.7×1.3×1.5m

|

|

General power

|

30kw

|

45kw

|

85KW

|

135KW

|

155KW

|

|

Motor power

|

30kw

|

30kw

|

55KW

|

90KW

|

90KW

|

|

Output

|

150-250kg/h

|

300-500kg/h

|

400-800kg/h

|

800-1000kg/h

|

900-1200Kg/h

|

Related Products

Our Company&Factory

Focus on puffing , food & machinery packaging

First manufacturer in food extruder in China

CE,AAA and ISO9000 certificates are available.

Our machines are sold all over the world and have won wide support and recognition from customers.

We always believe that quality products and services, is the best return to customers.

Sincerely hope to cooperate with you!

Certifications

Customer Visits&Exhibitions

FAQ

Q:Do you have your own factory?

A:

Yes,we have our own factory. Jinan Saixin Machinery Co., Ltd. was founded in 1995 and has 28 years of experience in developing and manufacturing food machinery.

Q: How long is the delivery time?

A:

Usually it is 5-10 days if the goods are in stock. Or it is 15-25 days if the goods are not in stock.

Q: Can I customize the specifications of the equipment I need?

A:

Of course, you can also provide us with your requirements, and we will recommend suitable equipment for you.

Q: What is your terms of payment ?

A:

Usually 30% T/T in advance , 70% balance before shipment.If you have other requirements, you can also contact our sales.

Q:What guarantee can I get if I buy your product?

A:

We will supply free parts during warranty period if machine have some problems. While we also supply free life long after-sales service.Also if you have any questions about how to operate your machine, we can talk a video or email.

SHIPPING

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

1. Inside: wrapping film; Outside: wooden case or customization

2. FCL; LCL

3. Delivery time: in 20 days

4.Shipping port: Qingdao/Tianjin/Shanghai

Hot Searches