- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

3500*3200*2800mm

-

Year:

-

2024

-

Power (kW):

-

300 kW

-

Weight (KG):

-

240000 KG

-

Raw material:

-

waste tire

-

Capacity:

-

500-1000kg/h

-

End product:

-

Rubber Particle

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Yuxi

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

3500*3200*2800mm

-

Year:

-

2024

-

Power (kW):

-

300 kW

-

Weight (KG):

-

240000 KG

-

Raw material:

-

waste tire

-

Capacity:

-

500-1000kg/h

-

End product:

-

Rubber Particle

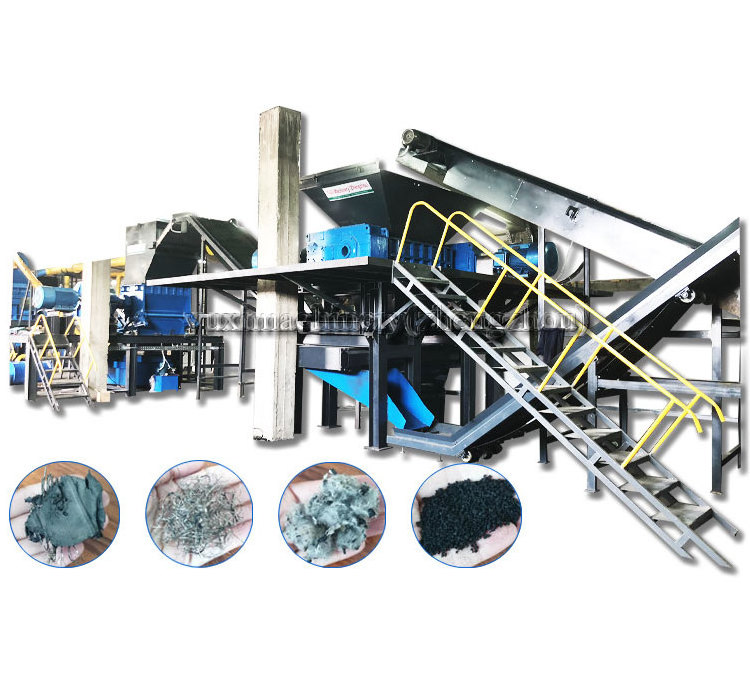

The rubber powder recycling production line is a new innovative equipment.

Rubber powder recycling production line is used for processing used tires and rubbers to fine rubber powders

End products size can reach 30-120 mesh free of steel wire and fiber

.

|

Capacity

|

500-10000kg/h

|

|

|

||

|

Scope of application

|

Diameter of the tire:400-3000mm

|

|

|

||

|

Output size

|

5-100 mesh,Can be Customized

|

|

|

||

|

Complete separation

|

The rubber Crumbs,Steel and Fibre can be separated automatically.

Adopt PLC control system,it is only need 4-6 persons to operate a Tire recycling(granule)production line with 3000kg/h capacity. Low energy consumption.The installed powder of Tire recycling production(granule)line with capacity 3000kg/h is about 800kw. |

|

|

||

|

Equipment required area

|

About 680square meter,7m height

|

|

|

||

|

Characteristic of blade

|

Long service life.High utilization,Multiple maintenance

|

|

|

||

Application Areas:

•

Paving sport ground:Runway, school sporting field, garden path, bowling alley, pavement, recreation field, basketball field, etc.

•Automobile industry:Train's floor, disc silk ribbon for braking, sole plate of automobile and truck, shake sleeve, seal stripe, buffer, shock absorber, daily material for ocean shipping, tyres and inner unerlay of tyres, etc.

•Architecture and equipment: Adhensive/sealant, floors of hospital, company, insulated rubber material, carpet cushion, grass cushion for family animal, extruded products, module products, coating, bricks, thin slice, water-proof material, etc.

|

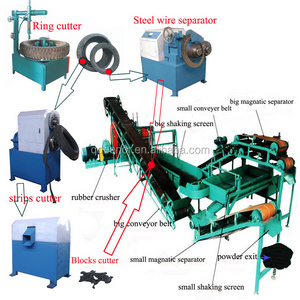

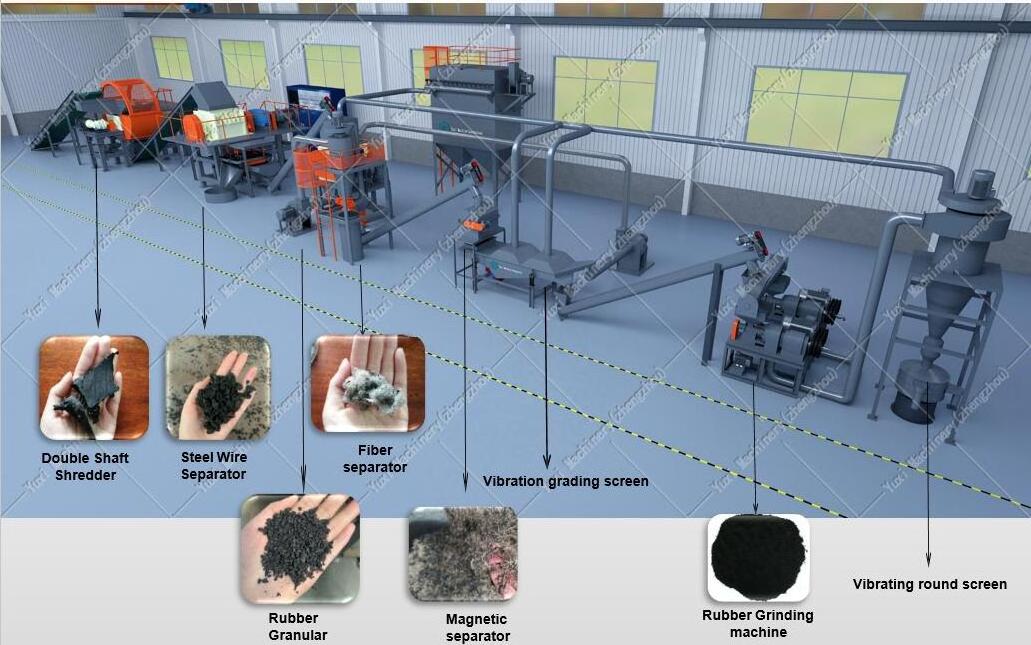

Double Shaft Shredder

|

|

The double shaft shredder pre-processes the

|

|

whole tire into approximately

50-80mm rubber

|

|

blocks.

|

|

Motor:

as per request

|

|

Steel Wire Separator

|

|

Input materials

≤50mm

tire rubber blocks finised

|

|

products

≤20mm. and

can

remove 96%

of the

|

|

tire steel wire.

|

|

Motor:

as per request

|

|

Reducer:

as per request

|

|

High Speed Crusher

|

|

Input materials ≤20mm

tire rubber blocks

|

|

finished products ≤2-6mm.

|

|

Motor:

as per request

|

|

Blades:

as per request

|

|

Product size:

one or more sizes are discharged at the same time.

|

|

Dust Collection

|

|

Dust collection system can collect dust and fiber

|

|

by the air pipe when the crushing machine

|

|

working.

|

|

Dust removal standard:

can be customized

|

|

according to the standards of different countries

|

|

Rubber Grinder

|

|

The rubber grinder is a device that

pulverizes 2-

|

|

6mm

pure rubber granules into a fine powder of

|

|

10-140 mesh

at room temperature.

|

|

Motor:

as per request

|

|

Product size:

one or more sizes are discharged at the same time.

|

1. Packaging: 1)Wrapped by protective film;

2)Packed by standard import & export wooden cases or carton boxes.

2. Shipping: By logistics; by automobile; by train; by shipping; by air etc.

1. Fast Response:All customer's messages will be replied within 24 hours

2. Free Consulting:We can provide free consulting services of tire recycling machines

3. Customized Layout:We will make the layout compatible to your working site

4. OEM/ODM:We can personal customized the equipment with your brand

5. Engineer Support:Our engineer will always participate during and after the trading

6. Brand New Equipment:e can guarantee every component is new and high quality brand

7. Logistic Team:We can transport the machine by sea, by train or by land

AFTER SALE:

1. Commissioning:We will test the machines before shipment and provide videos

2. Components Supply:We can guarantee stable supply of consumable components

3. Custom Clearance Support:We will provide PI, CI, PL, contract, CO, etc for your custom clearance

4. Product Manual:We will offer you operation manual of the machines

5. Installation:We will assemble the main parts, then mark all the joint parts and send videos to guide the installation and

training;We will assemble the main parts, then mark all the joint parts and send videos to guide the installation and

training.