- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

350

-

Product name:

-

CNC auto channel letter bending machine

-

Function:

-

Auotmatic feeding ,slotting ,bending and punching

-

Material width:

-

20-220mm

-

Material thickness:

-

0.3-2mm

-

Power:

-

2000w

-

Working voltage:

-

AC220/50-60HZ/41P

-

Working pressure:

-

0.4-0.8Mpa

-

Overall Size:

-

2740*1070*1610

-

Certification:

-

CE

-

Key words:

-

Auto letter bending machine

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

BYTCNC

-

Year:

-

2021

-

Weight (KG):

-

350

-

Product name:

-

CNC auto channel letter bending machine

-

Function:

-

Auotmatic feeding ,slotting ,bending and punching

-

Material width:

-

20-220mm

-

Material thickness:

-

0.3-2mm

-

Power:

-

2000w

-

Working voltage:

-

AC220/50-60HZ/41P

-

Working pressure:

-

0.4-0.8Mpa

-

Overall Size:

-

2740*1070*1610

-

Certification:

-

CE

-

Key words:

-

Auto letter bending machine

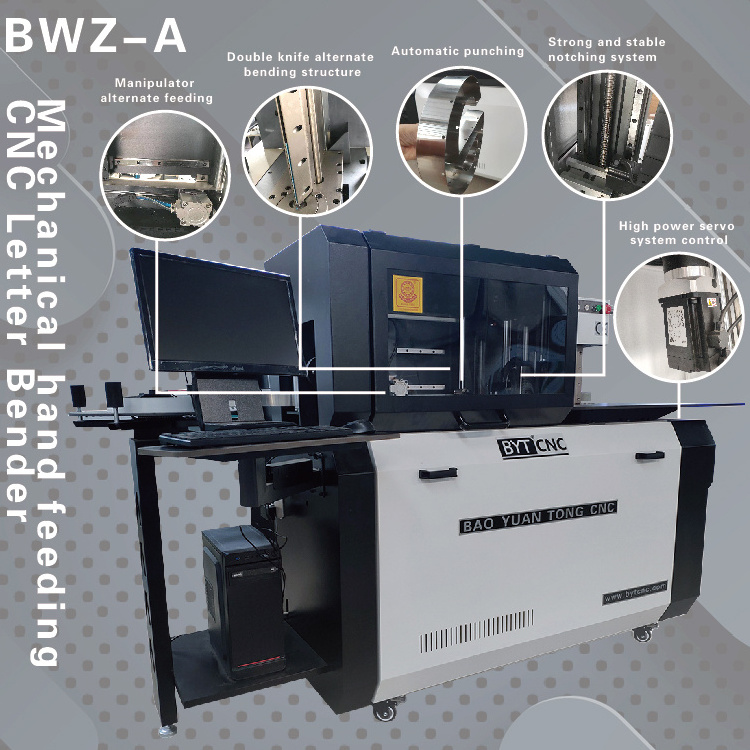

Products Information

|

Model

|

BWZ-A

|

|

Function

|

Automatic feeding,slotting and bending

|

|

Applicable Material

|

Stainless steel,Aluminum,Galvanized,Iron

|

|

Material Width

|

Flat Aluminum:≤220mm Stainless Steel:≤220mm

|

|

Material Thickness

|

Stainless Steel:0.3~1.5mm Flat Aluminum:0.3~2mm

|

|

Min-Bend Radius

|

5mm

|

|

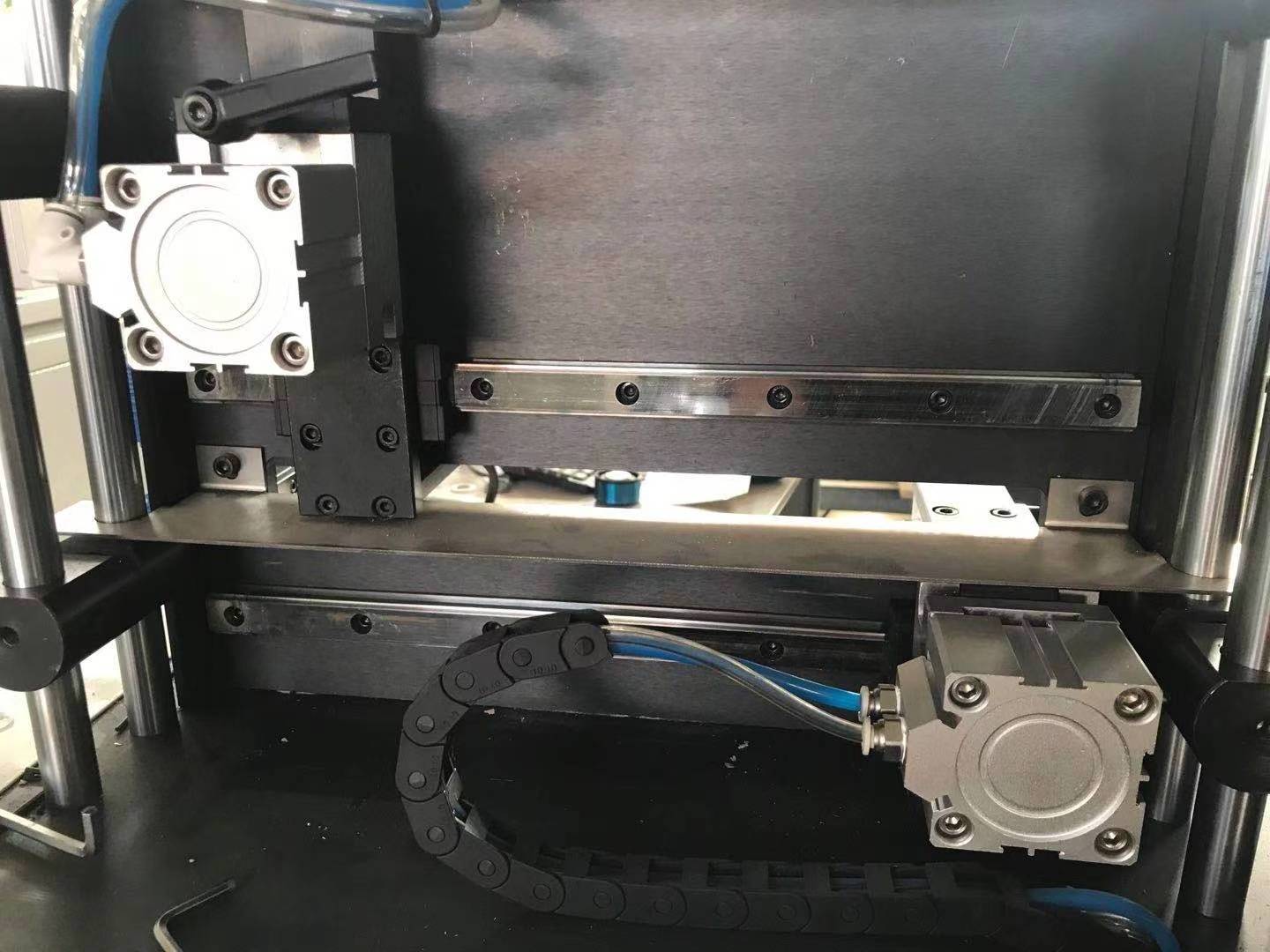

Feeding

|

Mechanical hand

|

|

Slot Motor

|

Inovance Servo Motor

|

|

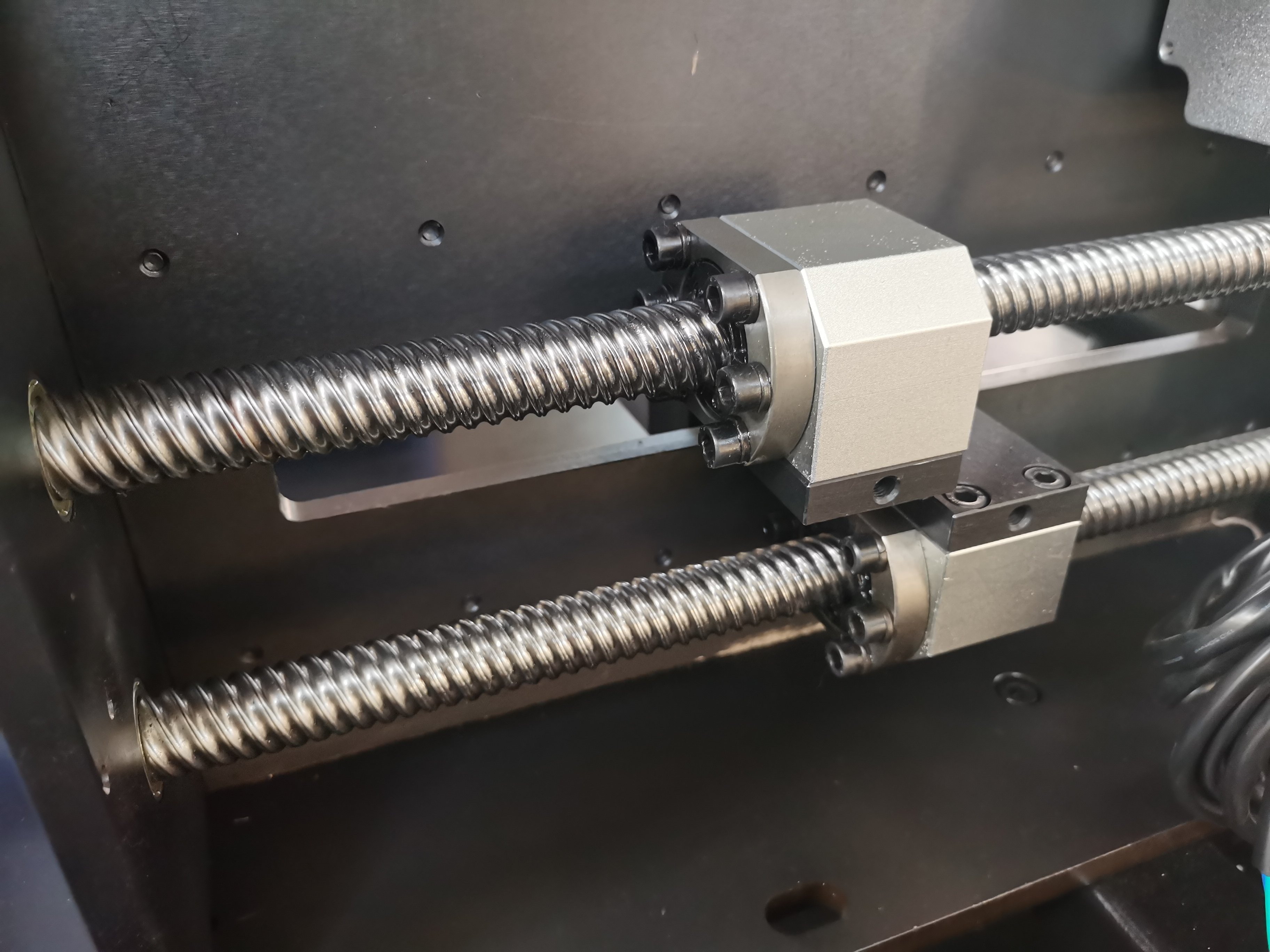

Bending

|

Inovance servo motor,Double rod lifting

|

|

Control System

|

ADT

|

|

Power

|

≤2000W

|

|

Air Pressure

|

0.4-0.8MPa

|

|

File Format

|

dxf, ai,plt

|

|

Working Voltage

|

220V/ 50-60HZ/1P

|

|

Net Weight(kgs)

|

350

|

|

Overall Size(mm)(L*W*H)

|

2740*1070*1610

|

Product Advantage

1.Use the

manipulator alternate feeding mechanism

, effectively ensure the stability of the feeding process.The material clip adopts structural casting, which can

improve the feeding grip and avoid scratches on the material.

2.

Double knife alternate bending structure

, high precision, strong stability.

3.With puching function ,more easy finish stainless steel punching ;Meantime if you don't need it , you also can close it in software.

4.

The planer is made of cemented carbide grain with low cost,

stable cutting and beautiful appearance.

5.

Lead screw plus four sliding blocks on two rails positioning drive,

greater strength, more stable cutting.

6.

High power servo system control

, high precision, high speed, high torque, improve the working efficiency .

7.

With length closed-loop control system

, length accuracy software control, error ≤0.1mm.

8.The whole machine is plated with hard chrome,

wear-resistant and corrosion-resistant.

9.The ADT software system is simple,

easy to learn and operate;with professional

, efficient and thoughtful service

Customer Feedback

Click below picture you will find letter bender detail video ,it is our customer recently feedback our

CNC letter bending machine

and

laser welding machine

. it is our duty to provide good service to our every customer

Related products

Our Service

Keep Quality and Service Be Our First Responsibility

Sales Service

Sales Service

1.Technical people have professional english ability and directly with customer communication.

2.24H/7D on line service , when you need we all will be here .

3.Before delivery , accept the international third party finish inspection .

4.Regular return visits to customers for technical guidance, and get high praise from customers.

4.Regular return visits to customers for technical guidance, and get high praise from customers.

5.For the products making , have professional technical engineer provide process guide .

Various Training Service

1.Provide U disk with detailed operation manual and video.

2.Via on line chat way service(QQ,whatsapp,wechat) for customer in any time.

3.Via teamviewer remote control software to provide on line guidance.

4. Customer come to our factory for learning how to operate the machines.

5.Engineer can go aboard for training if customer needed.

Hot Searches