- Product Details

- {{item.text}}

Quick Details

-

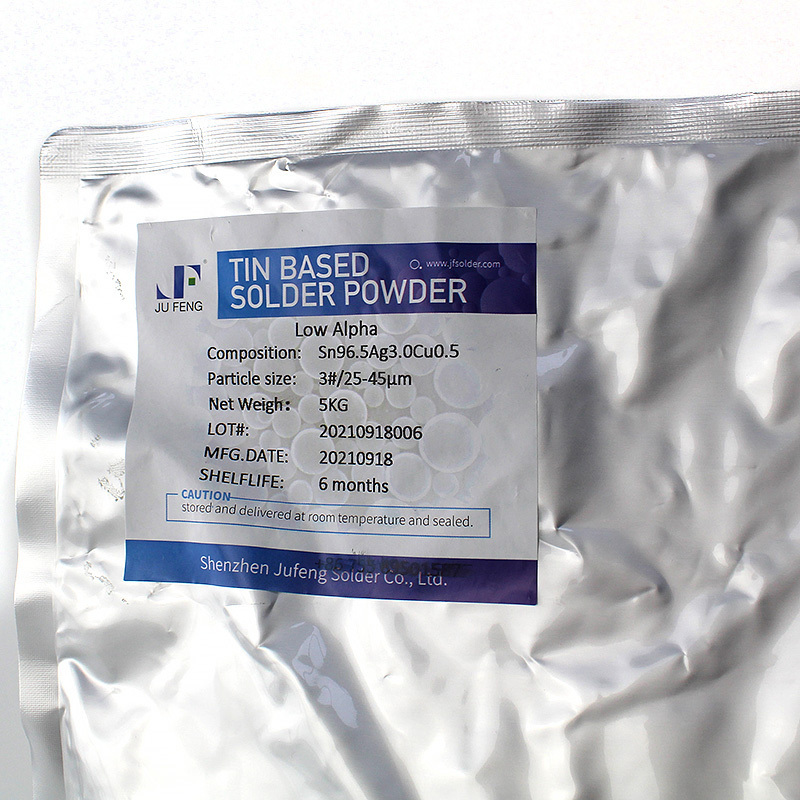

Model Number:

-

JF800901

-

Shape:

-

powder

-

Material:

-

tin, silver, cupper

-

Chemical Composition:

-

Sn96.5 % Ag3.0% Cu0.5%

-

Item:

-

Jufeng provided solder powder tin lead solder powder Sn96.5Ag3.0Cu0.5

-

Melting point:

-

217 degree

-

Color:

-

Silver gray

-

Powder size type:

-

T3, T4, T5, T6, T7

-

Packing:

-

5 kg per bag

-

Comments:

-

strong, bright soldering joint

-

Comparison:

-

best of tin lead series solder powder

-

Package:

-

bag/

Quick Details

-

Application:

-

to make solder paste

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Jufeng

-

Model Number:

-

JF800901

-

Shape:

-

powder

-

Material:

-

tin, silver, cupper

-

Chemical Composition:

-

Sn96.5 % Ag3.0% Cu0.5%

-

Item:

-

Jufeng provided solder powder tin lead solder powder Sn96.5Ag3.0Cu0.5

-

Melting point:

-

217 degree

-

Color:

-

Silver gray

-

Powder size type:

-

T3, T4, T5, T6, T7

-

Packing:

-

5 kg per bag

-

Comments:

-

strong, bright soldering joint

-

Comparison:

-

best of tin lead series solder powder

-

Package:

-

bag/

Jufeng provided solder powder tin lead solder powder Sn63Pb37 in T3, T4, T5, T6, T7

Solder powder Sn63Pb37 is a middle temperature leaded solder powder. the chemical composition is 63% tin and 37% lead, which are in eutectic structure. Such chemical structure makes the alloy process t he fix melting temperature, 183 degree celsius. This makes the alloy melt and solidify in the fix same temperature, thus the soldering joint is string, as it avoids the internal stress caused by the discordance of melting and solidifying.

In the tin leaded seris solder powder, Sn63Pb37 is the best, the soldering joint is strong, and the soldering spot is bright. JUFENG SOLDER, produces the solder powder by the powder machines imported from Germany, and using the high purity of tin and lead material, controlling the percentage of tin to lead. Thus our solder powder is of good quality eutactic structure.

Jufeng solder can prodice the tin lead solder power Sn63Pb37 in different types according to the customers' needs. the most usual one T3, then T4, and the unusual ones, T5, even T6, T7.

|

Item Sort |

Chemical composition (wt.%) |

||||||||

|

Sn |

Pb |

Sb |

Cu |

Bi |

Zn |

Fe |

Al |

Cd |

|

|

Sn63-Pb37 |

63 ± 0.5 |

37 ± 0.5 |

<0.20 |

0.08 |

<0.1 |

0.03 |

<0.02 |

<0.005 |

<0.002 |

|

tin solder powder Sn63Pb37(soldering material) |

|||

|

Accordance with the RMA grade of GB-T3131-2001. |

|||

|

Waving soldering wire:Good humidity, bright soldering point, beautiful, fast, no halogen, no ion pollution, high isolation resistance after cleaning, easily cleaning, environmental friendly |

|||

|

Item |

Index |

Item |

Index |

|

Soldering % |

2.0-2.2 |

Cleaning after soldering |

qualified |

|

Halogen % |

0 |

Isolation resistance after cleaning Ω |

>1×10 |

|

Extension rate % |

>86 |

PH |

neutral |

|

Acid KOHmg/g |

<35 |

Bronze mirror erosion after cleaning |

qualified |

|

Cleaning methods |

1: spraying brush, clean till no remains on PCB soldering side with deionisation liquid or distilled water (40-60). |

||

|

2: ultrasonic cleaning, fast and good effect if cleaning PCB soldering side on surface of ultrasonic liquid (40-60). |

|||

|

SMT solder powder |

melting point °C |

Type no. |

Application |

|

Sn63Pb37 |

183 |

Type2-7 |

PCB |

|

Sn96.5Ag3.5 |

222 |

Type2-7 |

SMT,cellphone component |

|

Sn96.5Ag3.0Cu0.5 |

217 |

Type2-7 |

SMD,SMT

|

|

Sn99.0Ag0.3Cu0.7 |

|||

|

Sn64Bi35Ag1 |

172 |

Type2-5 |

SMT,PCB |

|

Sn64.7Bi35Ag0.3 |

172 |

Type2-5 |

LED |

|

Sn42Bi57.6Ag0.4 |

138 |

Type2-5 |

LED |

|

Sn62Pb36Ag2 |

179 |

Type2-6 |

SMT,PCB |

|

Sn42Bi58 |

138 |

Type2-6 |

LED |

Packing

usually 5 kg per bag, 4 bags per bucket

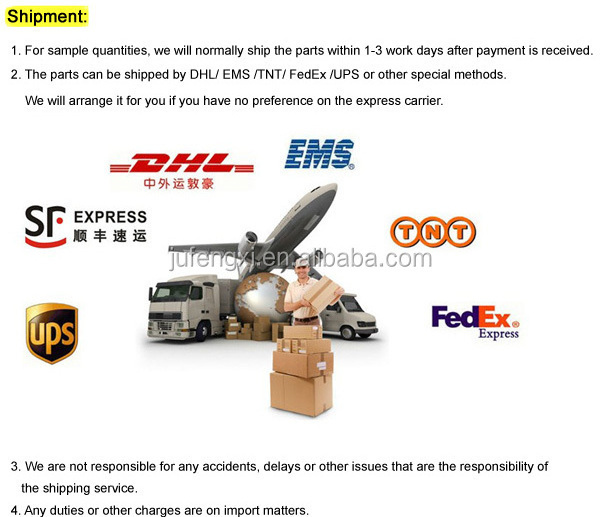

Shipping

1 Transaction details

Packaging & Delivery & MOQ & Payment details: pls see above related items

2 We support:

- Ø OBM

- Ø OEM

- Ø ODM

- Ø Designed Manufacturing for customized need

3 How to cooperate?

tell demands >> choose products or design for demands >> sample testing >> rechoose or redesign and retest >> send quotation >> place PO >> send PI >> make payment >> production >> shipping >> feedback >> enhance service and product >> further cooperation.

Flow Chart for Quality Guarantee

|

Material Inspection ( a. Our QA Department b. National Certification Department Note: Major material ) —> Flux character Inspection —> Process products —> Solder Paste Inspection —> Solder Paste Package Inspection —> Finished Products Inspection —> Shipment Choice Inspection |

Feedback Flowchart for Product Quality

|

Client —> Market Representative —> Market Manager —> Engineering Department —> Find out Problems through from Client —> Improvement (Engineering Department) —> QA Department —> Feed Back to Market Manager —> Client |