- Product Details

- {{item.text}}

Quick Details

-

Design Printing:

-

No printing

-

Material:

-

Cloth

-

Feature:

-

Heat-Resistant

-

Use:

-

MASKING

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

TESA

-

Model Number:

-

TESA 4657

-

Product Name:

-

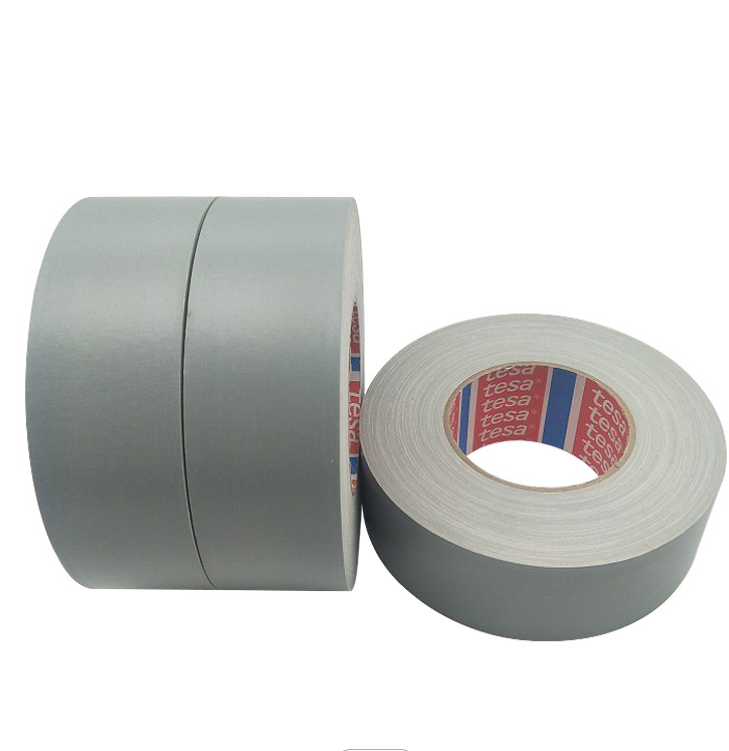

Tesa 4657 duct cloth tape

-

Backing material:

-

Mesh cotton woven cloth

-

Structure:

-

Single side cloth tape

-

Color:

-

Sliver&Black&Wray

-

Thickness:

-

0.29mm

-

Jumbo roll size:

-

965mm*50m

-

Application:

-

Pipe sealing/Sandblasting masking

-

Advantage:

-

High bonding strength on foam

-

Sample:

-

A4 size Freely Provided

-

Shape:

-

Customized Die Cutting

Quick Details

-

Adhesive:

-

Rubber

-

Adhesive Side:

-

Single Sided

-

Adhesive Type:

-

Pressure Sensitive

-

Design Printing:

-

No printing

-

Material:

-

Cloth

-

Feature:

-

Heat-Resistant

-

Use:

-

MASKING

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

TESA

-

Model Number:

-

TESA 4657

-

Product Name:

-

Tesa 4657 duct cloth tape

-

Backing material:

-

Mesh cotton woven cloth

-

Structure:

-

Single side cloth tape

-

Color:

-

Sliver&Black&Wray

-

Thickness:

-

0.29mm

-

Jumbo roll size:

-

965mm*50m

-

Application:

-

Pipe sealing/Sandblasting masking

-

Advantage:

-

High bonding strength on foam

-

Sample:

-

A4 size Freely Provided

-

Shape:

-

Customized Die Cutting

Products Description

|

Product name

|

Tesa 4657 cloth duct tape

|

|

Color

|

Black/Gray

|

|

Thickness

|

0.29mm

|

|

Jumbo roll size

|

965mm*50M

|

|

Long term temperature resistance

|

80° C

|

|

Short term temperature resistance

|

180° C

|

|

Custom service

|

Slitting / Die cutting / Packaging

|

|

Free sample

|

A4 size free sample

|

|

Advantage

|

1. Even under high temperature environment, there is no residual glue after stripping

2. Excellent aging resistance

3. Paint solvent resistance

4. Very suitable for die cutting

|

|

Product application

|

1. Temperature resistant shielding during vehicle and machinery production

2. Shielding of window edge

3. Oven drying can even be repeated

4. Permanent internal and external plugging

5. Plugging of screw mounting hole and drain hole

6. Partial shielding during impregnant treatment

7. Fixing of flat wire harness

8. Shielding during electrostatic powder coating

|

Hot Searches