- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

2100*1600*1550

-

Weight:

-

7830kg

-

Output product name:

-

Bread

-

Name:

-

laminating croissant machine

-

Usage:

-

bread processing

-

Material:

-

304 Stainless Steel laminating croissant machine

-

Color:

-

Silvery

-

Power Source:

-

Electric Power

-

Capacity:

-

200-800Kg/h laminating croissant machine

-

Function:

-

Multifunctional

-

Type:

-

Automatic

-

Item:

-

bread processing

-

MOQ:

-

1 Set

-

After Warranty Service:

-

Video technical support

-

Local Service Location:

-

None

-

After-sales Service Provided:

-

Video technical support

-

Certification:

-

CE

Quick Details

-

Brand Name:

-

HNOC

-

Place of Origin:

-

Henan, China

-

Power:

-

4kw

-

Dimension(L*W*H):

-

2100*1600*1550

-

Weight:

-

7830kg

-

Output product name:

-

Bread

-

Name:

-

laminating croissant machine

-

Usage:

-

bread processing

-

Material:

-

304 Stainless Steel laminating croissant machine

-

Color:

-

Silvery

-

Power Source:

-

Electric Power

-

Capacity:

-

200-800Kg/h laminating croissant machine

-

Function:

-

Multifunctional

-

Type:

-

Automatic

-

Item:

-

bread processing

-

MOQ:

-

1 Set

-

After Warranty Service:

-

Video technical support

-

Local Service Location:

-

None

-

After-sales Service Provided:

-

Video technical support

-

Certification:

-

CE

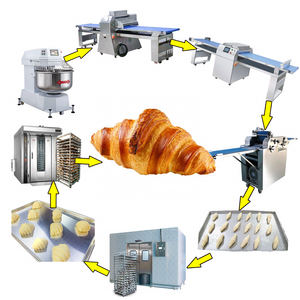

HNOC automatic turkish bread production line laminating croissant machine

Advantages

1.20-120pcs/min,1.5times faster than similar machine.

2.Error of each product within 1g, and we will have the improvements every year.

3.Easy to operate the machine, you can handle the machine with 3 hour training.

4.All the electric components adopt the one stop solution provided by DELTA, such as PLC, invertor.

5.The machine can memory the recipe, just need to adjust the parameters one time for single product.

6.Available for various kind of food, including the loaf bread, burger bread, filled bread, whole wheat bread,etc.

7.It is designed for factory.

8.Material adopt SUS304, food grade type.

9.Easy to disassembly the parts, and cleaning the machine need a little time.

1)Provide factory layout according to your factory size in advance;

2)Provide the basic formula;

3)Inspect the machine before leaving the factory;Oversea installation and commissioning equipment;

4)Technician will work with your workers together and teach your workers how to install machines,

how to operate machines, how to maintain machines during daily working;

5)Our engineers will teach your workers how to clean the extruder, how to change the screw,

how to change barrel etc, and provide technology support with you forever;

6)Provide English Version of Installation / Operation / Service / Maintenance Manual.