- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380

-

Power:

-

customized

-

Dimension(L*W*H):

-

customized

-

Weight (KG):

-

6000

-

Marketing Type:

-

New Product 2023

-

Evaporation Capacity(kg/h):

-

customized

-

Function:

-

Drying+Dehumidity

-

After-sales Service Provided:

-

1 Year

-

Raw material:

-

SS304/SS316/Q235

-

Heating source:

-

Steam

-

Temperature range:

-

70-90

-

Application material:

-

Food & Beverage

-

Power supply:

-

380V 50Hz Three Phase (customized)

-

Advantage:

-

Easy Operation High Efficiency

Quick Details

-

Type:

-

Rotary Drying Equipment

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

ZHONGBO

-

Voltage:

-

380

-

Power:

-

customized

-

Dimension(L*W*H):

-

customized

-

Weight (KG):

-

6000

-

Marketing Type:

-

New Product 2023

-

Evaporation Capacity(kg/h):

-

customized

-

Function:

-

Drying+Dehumidity

-

After-sales Service Provided:

-

1 Year

-

Raw material:

-

SS304/SS316/Q235

-

Heating source:

-

Steam

-

Temperature range:

-

70-90

-

Application material:

-

Food & Beverage

-

Power supply:

-

380V 50Hz Three Phase (customized)

-

Advantage:

-

Easy Operation High Efficiency

FEATURES AT A GLANCE

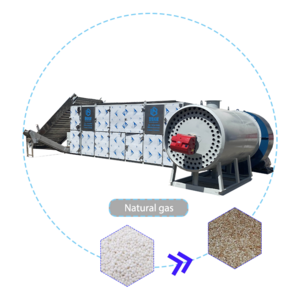

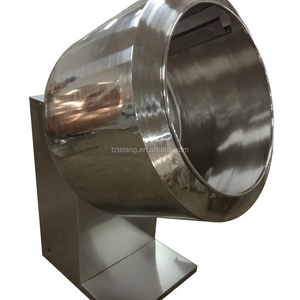

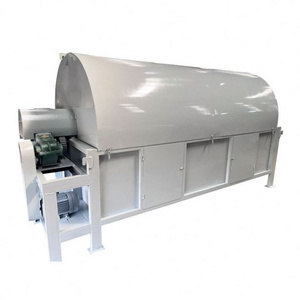

Rotary Dryer Machine

Rotary Dryer Machine

Why Choose Us

Initiated in 1993,

Wenzhou Jiangbo Dairy Product Equipment Manufacturing Factory has gone through 20 manufacturing years in Diary&Beverage industry. 20 years of experience brought us a first batch of specialized frontline technical workers and core engineers, winning widely reputation and faith among domestic market. A lot of supports from our clients promoting Jiangbo to move forward, We do not just stay where we begin.

In year of 2013,

we established Zhejiang Zhongbo Mechanical Technology Co.,Ltd.In an effort to keep pace with automation technology development, talents and advanced automatic equipment were constantly introduced, laser cutting, automatic polishing, automatic welding etc .Within 10 years, we have took a big step in production technology, furthermore broadened our production scope involving to Pharmaceutical and Chemical filed.

In year of 2021

, we has established and passed ISO9001:2000 quality assurance system to improve production management and after-sale services.

Certifications

Automation Technology

Argon arc welding is a welding technology that uses argon gas as a shielding gas. It is to

pass argon protective gas around the arc welding to isolate the air outside the welding area and prevent the oxidation of the

welding area

pass argon protective gas around the arc welding to isolate the air outside the welding area and prevent the oxidation of the

welding area

Laser cutting machine

Improve stability and precision of cutting

Improve stability and precision of cutting

Polishing machine

used for equipment surface

Manufacturing Workshop

Delivery & Packaging

FAQ

Q: What is your main products?

A: we are specialized in plant equipment used for evaporation, extraction, concentration and pasteurization process.

Q: Is available overseas engineer installation?

A:Yes, There are to be 3 phases with regards to overseas installation: First, Technical Assistance by video, telephone or email.

Then, Despatch of regular spare parts from the Seller’s stock. Last, Departure of required service engineer(s).

Q:Could i get customization service?

A: Yes, please contact us for details.

Q:What is your production experience?

A:Almost 20 years in Dairy&Beverage field, Pharmaceutical field, Chemical field.

Q: What is you advantage?

A:Source Factory, competitive price, reputed guarantee, in-time after-sale services

A: we are specialized in plant equipment used for evaporation, extraction, concentration and pasteurization process.

Q: Is available overseas engineer installation?

A:Yes, There are to be 3 phases with regards to overseas installation: First, Technical Assistance by video, telephone or email.

Then, Despatch of regular spare parts from the Seller’s stock. Last, Departure of required service engineer(s).

Q:Could i get customization service?

A: Yes, please contact us for details.

Q:What is your production experience?

A:Almost 20 years in Dairy&Beverage field, Pharmaceutical field, Chemical field.

Q: What is you advantage?

A:Source Factory, competitive price, reputed guarantee, in-time after-sale services

Hot Searches