- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380v

-

Power:

-

5500W

-

Weight:

-

280 KG

-

Dimension(L*W*H):

-

1700*850*1500mm

-

Year:

-

2023

-

Name:

-

corn puff machine

-

Function:

-

Multifunctional

-

Material:

-

Food Grade Stainless Steel

-

Advantage:

-

Easy Operation High Performance

-

After Warranty Service:

-

Video Technical Support

-

MOQ:

-

1 Set

-

Package:

-

Wooden Case

-

Application:

-

Food Processing Machine

-

Capacity:

-

30-40kg/h

-

Product name:

-

corn puff making machine

Quick Details

-

Marketing Type:

-

New Product 2024

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

TD

-

Voltage:

-

380v

-

Power:

-

5500W

-

Weight:

-

280 KG

-

Dimension(L*W*H):

-

1700*850*1500mm

-

Year:

-

2023

-

Name:

-

corn puff machine

-

Function:

-

Multifunctional

-

Material:

-

Food Grade Stainless Steel

-

Advantage:

-

Easy Operation High Performance

-

After Warranty Service:

-

Video Technical Support

-

MOQ:

-

1 Set

-

Package:

-

Wooden Case

-

Application:

-

Food Processing Machine

-

Capacity:

-

30-40kg/h

-

Product name:

-

corn puff making machine

Video

Products Description

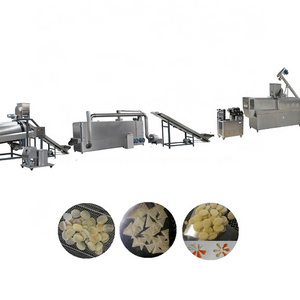

Stainless steel single screw snack food extruder machine

adopt corn, rice, wheat, oat, barley etc as ingredients to make puffed snack

. Through frication of screw and barrel, the grains are cooked in the extruder. Forming is at the die face cutter. The product shape is determined by a combination of the die aperture,

including ball, tube, stick, ring, fruit loop, star, wheel and flower etc

.All the snack food produced by the equipment are crispy, easy to be digested and popular with moder people home and abroad.

Advantage:

1. We can produce large capacity extruders with maximum output up to 250kg/h.

2. Screw material: high strength and wear resistance.

3. The feeding system, extrusion system and cutting system all adopt speed-adjusting frequency converters. Food-grade stainless steel screw feeding device ensures stable feeding of materials throughout the food process.

4. Adopt Delta frequency converter to ensure better operation of the extruder.

5. The operation is automated, intelligent, and pollution-free.

2. Screw material: high strength and wear resistance.

3. The feeding system, extrusion system and cutting system all adopt speed-adjusting frequency converters. Food-grade stainless steel screw feeding device ensures stable feeding of materials throughout the food process.

4. Adopt Delta frequency converter to ensure better operation of the extruder.

5. The operation is automated, intelligent, and pollution-free.

Technical Parameters

|

Model

|

Power(kw)

|

Capacity(kg/h)

|

Feed power(kw)

|

Cut power(kw)

|

Overall dimensions(mm)

|

Weight(kg)

|

|

DGP40-B

|

5.5

|

30-40

|

0.4

|

0.4

|

1700*850*1500

|

280

|

|

DGP50-B

|

11

|

60-80

|

0.4

|

0.4

|

1800*880*1500

|

320

|

|

DGP60-B

|

15

|

100-120

|

0.4

|

0.4

|

1830*800*1730

|

380

|

|

DGP70-J

|

18.5

|

150-180

|

0.4

|

0.4

|

2050*900*1400

|

490

|

|

DGP80-J

|

22

|

200-250

|

0.6

|

0.6

|

2100*900*1400

|

580

|

Product Details

Display of molds with different shapes

Product Photos

Packaging & Shipping

Contact with me

Hot Searches