- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

350 KG

-

Place of Origin:

-

Henan, China

-

Voltage:

-

220v/380v/customized, 220v/380v/customized

-

Application scope:

-

Taro balls, pearl balls, rice balls

-

Raw materials:

-

starch,potato starch,rice powder Cassava starch etc

-

Related machine:

-

mixer,Rounding machine

-

Application:

-

sago tapioca pearl machine

-

Material:

-

Food Grade Stainless Steel 304

-

Feature:

-

High Efficiency Easy Operation

-

Type:

-

tapioca pearl machine for bubble tea

-

Warranty:

-

1 Year

-

Core Components:

-

PLC, Bearing, Motor, Gear

Quick Details

-

Machinery Capacity:

-

500-600kg/batch

-

Brand Name:

-

ocean

-

Dimension(L*W*H):

-

780*750*1300mm

-

Weight:

-

350 KG

-

Place of Origin:

-

Henan, China

-

Voltage:

-

220v/380v/customized, 220v/380v/customized

-

Application scope:

-

Taro balls, pearl balls, rice balls

-

Raw materials:

-

starch,potato starch,rice powder Cassava starch etc

-

Related machine:

-

mixer,Rounding machine

-

Application:

-

sago tapioca pearl machine

-

Material:

-

Food Grade Stainless Steel 304

-

Feature:

-

High Efficiency Easy Operation

-

Type:

-

tapioca pearl machine for bubble tea

-

Warranty:

-

1 Year

-

Core Components:

-

PLC, Bearing, Motor, Gear

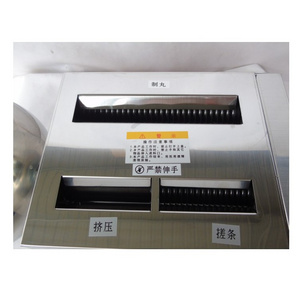

Product Overview

Best Price Automatic tapioca pearl forming machine jelly bubble tea

making machine sago tapioca pearl machine

taro ball sago tapioca pearls molding cutting forming machine bubble tea tapioca pearls

making machine Application:

* taro ball, tapioca pearl, sago seeds, glutinous rice ball, (high-efficiency, high-quality forming)

* Innovative design of the oil-tank-free drive structure of rubbing roller, will not cause secondary pollution during the

production process;

taro ball sago tapioca pearls molding cutting forming machine bubble tea tapioca pearls

making machine Operating ways:

1. 1. Put 5Kg glutinous rice powder into the machine, add 2.25kg boiling water, put into the mixer machine to

mix evenly, use hands to press the dough into a flat square,thickness within 20-25 mm ,then put into the feed hopper to processed.

1. 2. Grinding powder, should press wet sanding powder dry, take a third of rice steamed 89 mature, put into the mixer machine,

combine one/two third wet rice noodles, plus a third of dry rice flour and mix at the same time, use hands to press powder into a

flat square,20-25 mm thickness ,processed into the feed hopper, after forming, dried 10-20 minutes later, it is ready to pack.

Materials Processing Machine Solutions:

* Cassava Starch Processing Machine(Tapioca Starch Processing Machine);

* Potato Starch Making Machine;

* Sweet Potato Starch Making Machine;

* Canna Edulis Ker Starch Processing Machine;

* Cassava Flour(HQCF) Machine(High Quality Cassava Flour Processing Machine);

* Cassava Garri Processing Machinery(Gari Processing Machine);

* Cassava Fufu Processing Machine(Fufu Machine);

* Cassava Chips Making Machine(Cassava Cutting Production Line);

* Yam Flour Processing Machine(Amala Yam Flour Making Machine).

Product Parameter

| Model | OR-022B |

| Capacity | 300KG/H(as 9mm diameter ball) |

| Voltage | 380V,50HZ |

| Power | 3KW |

| Roller diameter | 100mm |

| Roller mould length | 385mm |

| Extruder mould length | 400mm |

| Diameter | 1700*980*1360mm |

Final Product: