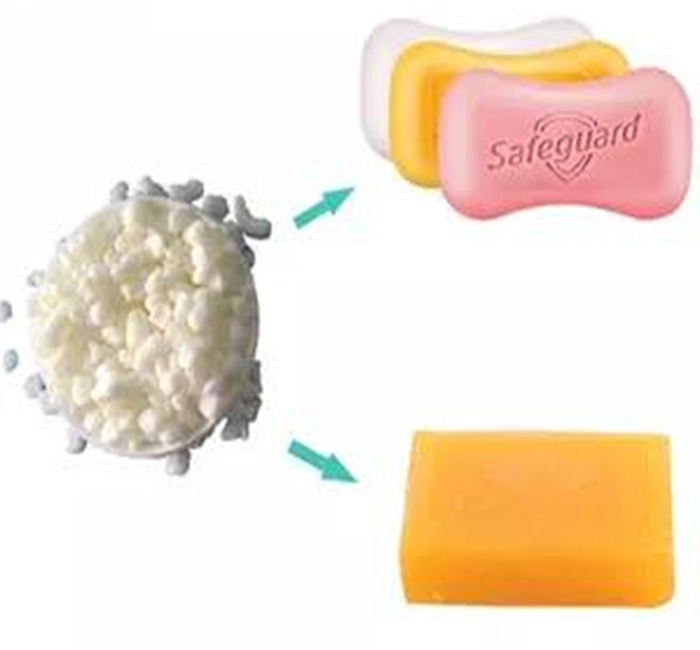

The raw materials for the production of toilet soap and transparent soap are fully and uniformly stirred and mixed to refine the

granulation. Various auxiliary materials, additives and flavors are completely mixed into the granulation to meet the formula

requirements.

- Product Details

- {{item.text}}

Quick Details

-

Final Soap Shape:

-

Oval Customized

-

Heating method:

-

Steam

-

Function:

-

making soap

-

Capacity:

-

100/500/1000/2000/3000 KG/H

-

Related machines:

-

Double Screw Vacuum Plodder Machine

-

Color:

-

Clients Request

Quick Details

-

Place of Origin:

-

henan

-

Marketing Type:

-

2021 new production

-

Application:

-

Laundry Soap Production Line

-

Final Soap Shape:

-

Oval Customized

-

Heating method:

-

Steam

-

Function:

-

making soap

-

Capacity:

-

100/500/1000/2000/3000 KG/H

-

Related machines:

-

Double Screw Vacuum Plodder Machine

-

Color:

-

Clients Request

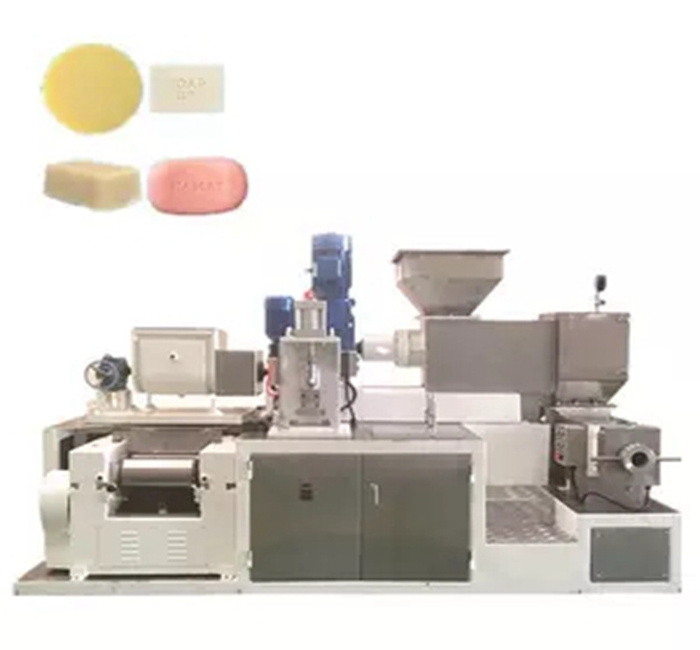

Product Overview

bar soap making machine Fully automatic laundry bar soap making machine Small Liquid Bar Soap Making Machine

This laundry soap line has two parts: saponification line and finishing line.

Saponification line uses oil and caustic soda as the raw material, yield 4-12 ton/day. Saponifying and drying naturally.

Finishing line uses the dry soap base as the material, capacity 500 kg/hr. After mixing, grinding, extruding soap bar continuously stamping and cutting, to produce from low to high quality laundry soap bar. Vacuum plodder makes the soap’s structure tight and not easy to crack.

Saponification line uses oil and caustic soda as the raw material, yield 4-12 ton/day. Saponifying and drying naturally.

Finishing line uses the dry soap base as the material, capacity 500 kg/hr. After mixing, grinding, extruding soap bar continuously stamping and cutting, to produce from low to high quality laundry soap bar. Vacuum plodder makes the soap’s structure tight and not easy to crack.

Details Images

The entire production line has three conveyor belts to transport materials, etc.

soap fined machine presses, squeezes and grinds the soap base to achieve fine finishing, and finally discharges it into shape

continuously. The extended barrel and screw can effectively squeeze the soap body and enhance the density of the soap material.

continuously. The extended barrel and screw can effectively squeeze the soap body and enhance the density of the soap material.

The three-roll mill is mainly used for grinding soap particles. The three rollers are arranged horizontally at different speeds.

Soap particles squeeze and shear each other on the surface of the roller to achieve the grinding effect. The fuselage adopts steel

structure, strong and sturdy. The surface of the roller is made of cold hard alloy material, and the roller is wear-resistant. The

gap between the rollers is easy to adjust to achieve different grinding effects and production capacity requirements.

Soap particles squeeze and shear each other on the surface of the roller to achieve the grinding effect. The fuselage adopts steel

structure, strong and sturdy. The surface of the roller is made of cold hard alloy material, and the roller is wear-resistant. The

gap between the rollers is easy to adjust to achieve different grinding effects and production capacity requirements.

The Vacuum plodder machine is composed of two-stage discharge screw, and adopts independent closed deceleration transmission

system. The soap granules are made under vacuum, so that the soap granules are compressed, and after being extruded, they are

continuously output in the form of soap bars through the muzzle. .

system. The soap granules are made under vacuum, so that the soap granules are compressed, and after being extruded, they are

continuously output in the form of soap bars through the muzzle. .

Soap cutting machine, stamper, refrigerator, electrical box, etc. complete the soap cutting, forming and stamper.

processing flow

PRODUCT SPECIFICATIONS

Good Price Small Scale Toilet Laundry Soap Bar Production Line BAR SOAP PRODUCTION LINE

|

No

|

Item

|

Main Specifications

|

|

1

|

Oil Gauge Tank

|

Size: φ1000X1550, 1.2 m3;

|

|

2

|

Liquid Caustic Soda Gauge Tank

|

Size: φ1000X1550, 1.2 m3;

|

|

3

|

Saponification Tank

|

Size: φ2200 X 2500, 10 m3.

Coiler inside. |

|

4

|

Liquid Soap Tank

|

Size: 1000 x 1000 x 1000 mm..

|

|

5

|

Oil pump, liquid caustic soda pump

|

1.5 kW/set.

|

|

6

|

Pipes, Valves, Platform

|

|

|

7

|

Heat Insulating Materials

|

Keep warm for the saponification tank and pipes.

|

|

8

|

Distribution Box

|

For oil pump and caustic soda pump.

|

Exhibition

Product packaging

FAQ

1..How do you guarantee that we can receive the goods ordered?

We are a legal company supervised by the government and also the Alibaba company as well as the third parties, what is more

important, honesty and trustworthiness are our basic principle. Please trust us that we will offer the best to our client you.

We are a legal company supervised by the government and also the Alibaba company as well as the third parties, what is more

important, honesty and trustworthiness are our basic principle. Please trust us that we will offer the best to our client you.

2.Can the motor work with our local power supply?

When you place the order, you could tell us the power supply available to your country.If our standard motor can not work with it,

we would modify it for you, maybe it will occurs few extra cost.

When you place the order, you could tell us the power supply available to your country.If our standard motor can not work with it,

we would modify it for you, maybe it will occurs few extra cost.

3:Which kind of package you will use ?

Standard export wooden box , if machine weight , We will use iron cage plus wooden box .

4: What is your payment term?

We accept 100% payment by T/T /LC ,50% to 50% by T/T or Credit card.

Standard export wooden box , if machine weight , We will use iron cage plus wooden box .

4: What is your payment term?

We accept 100% payment by T/T /LC ,50% to 50% by T/T or Credit card.

contact us

Andy :Phone/ whatsapp/wechat : 0086 13691410364

Hot Searches