- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

China

-

Product name:

-

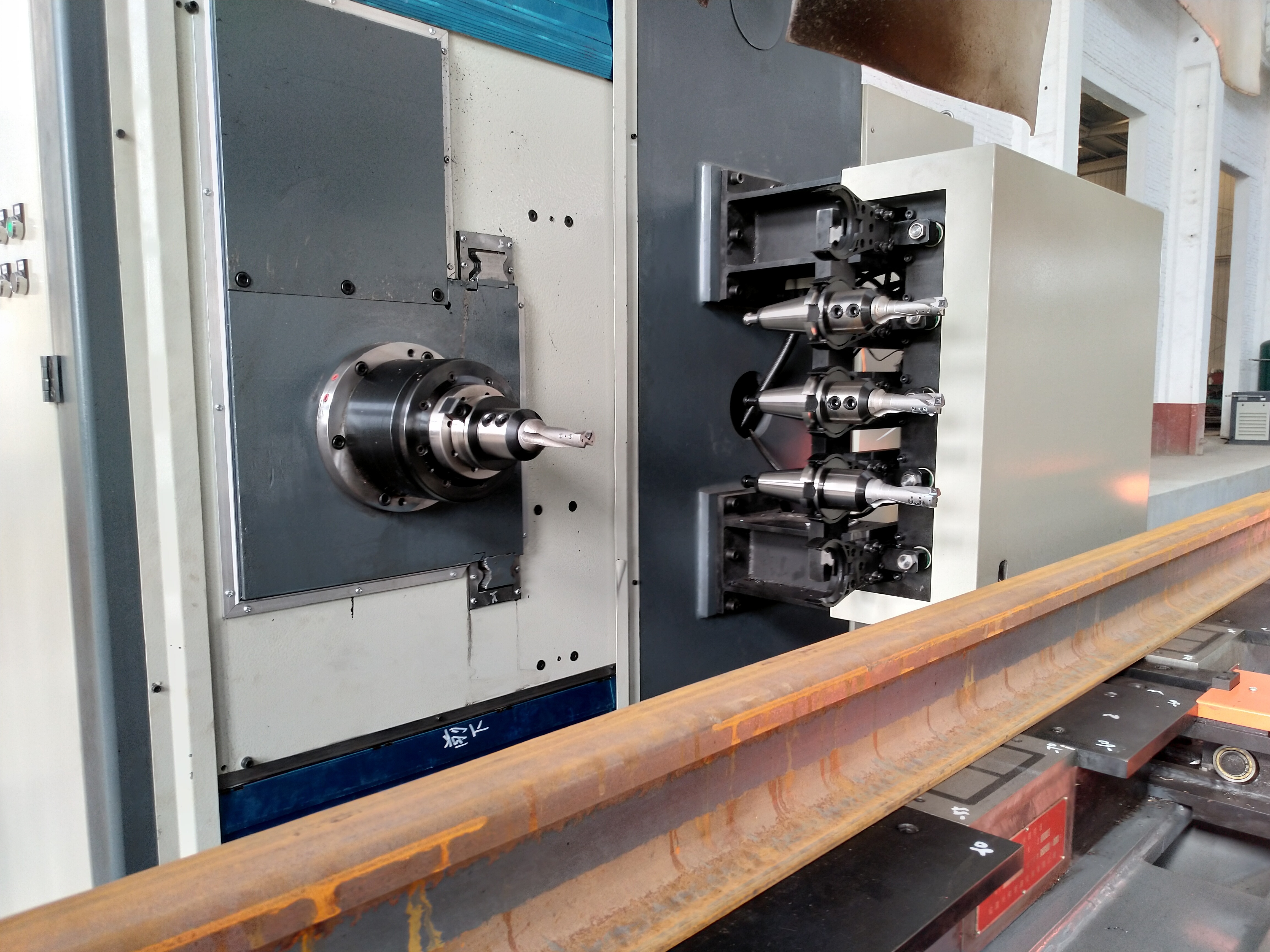

High Speed CNC Drilling Machine For Rails

-

Application:

-

Process holes of the basic rail

-

Keyword:

-

Rail Drilling Machine

-

Color:

-

Customized Option

-

Spindle taper:

-

BT50

-

Spindle Speed(r/min):

-

3000

-

Max. drilling diameter:

-

40

-

Workpiece No. (Kg\m):

-

40-75

-

Workpiece length (m):

-

6-25

-

Spindle Qty:

-

1 or 2

Quick Details

-

type:

-

Horizontal

-

Max. Drilling Dia. (mm):

-

40

-

Range of Spindle Speed(r.p.m):

-

120 - 3000

-

Place of Origin:

-

China

-

Product name:

-

High Speed CNC Drilling Machine For Rails

-

Application:

-

Process holes of the basic rail

-

Keyword:

-

Rail Drilling Machine

-

Color:

-

Customized Option

-

Spindle taper:

-

BT50

-

Spindle Speed(r/min):

-

3000

-

Max. drilling diameter:

-

40

-

Workpiece No. (Kg\m):

-

40-75

-

Workpiece length (m):

-

6-25

-

Spindle Qty:

-

1 or 2

|

Model

|

TRDL25

|

|

Workpiece No. (Kg/m)

|

40-75

|

|

Workpiece length (m)

|

6-25

|

|

Spindle Qty.

|

1 or 2

|

|

Morse taper

|

BT50

|

|

Drilling diameter (rpm)

|

9.8-40

|

|

Max. Rotation speed (rpm)

|

3000

|

|

Motor power (KW)

|

22

|

|

Quantity of CNC axis

|

3

|

2.The drill bit power box adopts the pillow structure, adopts the large size roller guide, it is installed on the large section size column, improves the rigidity of the machine, moves up and down through the AC servo motor to drive the ball screw pair, the upper part is fitted with a balanced cylinder.

3. Drilling power box using imported high-speed presicion spindle, with spindle servo motor. Automatic tool-changing function, equipped with four tool position of the linear tool magazine, improve processing efficiency.

4. Installed a pressing cylinder on the moving column, when processing rail, press the workpieces and improve the clamping stiffness.

5. The motion of the main machine on the machine bed and the movement of the power head on the column have a single magnetic ruler detecion system, which can ensure the positioning accuracy of the coordinate movement.

6. The drilling tools adopted indexable carbide U drill, the spindle adopted hollow ventilation fog cooling.

7. The loading and unloading system is used in the loading and unloading process of ordinary rail, which can realize semi-automatic production, recuce the labor intensity of workers, and greatly improve the labor productivity.

This machine will be packaged into 40GP container, the electrical parts will be packaged by the wooden box, and the mechnical parts with plastic wraps. Then fasten by the strong wireropes.

Q1. Are you a Manufacturer or a trading company?

A1.We are the manufacture, integrating with design, machining and assembling for angle machine.

Q2. Do you have stock product ready to deliver?

A2. In order to satisfy with the customer for fast delivery, we have certain amount of machines in stock, you can check the machine on LIVE-DEMONSTRATION at any time.

Q3. How do you deliver the finished products?

A3. The machine is mostly delivery by sea, rail way or road for some exception. For some urgent part or shipping document we delivered by air or Express like TNT, FEDEX,DHL,UPS,EMS, Etc.

Q4. How can you guarantee the after-sales service?

A4. We have the special after-sales service department, they will provide training program for operation and trouble shouting during installation. And they will visit the customer regularly for service.

all questions will be answered within 3 hours and 90% problem will be solved within 24 hours.

Q5. What's delivery time for the angle machine.

A5. Within 20 days after payment.

Q6. How can you guarantee your finished angle machine quality?

A6. First, the machine will have 8 hours idle running;

Second, we will test the machine with the material working together.