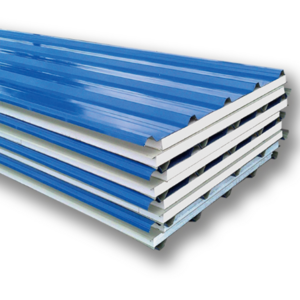

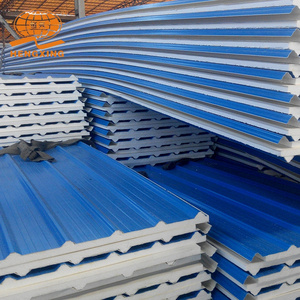

The polyurethane roof panels are connected by dark nails, and the panels are closely overlapped.The unique waterproof groove design can effectively prevent the penetration of rainwater and avoid the phenomenon of cold bridge.The 40mm crest height greatly improves the bearing capacity of the roof panel. While ensuring the thermal insulation effect of the building, it can effectively reduce the construction cost of customers, and the roof slope can be as low as 3%.

Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

SH

-

Model Number:

-

152

-

Product name:

-

Polyurethane Foam Sandwich Panel

-

Keyword:

-

Pu Sandwich Pane

-

MOQ:

-

1 Square Meters

-

Thickness:

-

50/75/100/150/200mm

-

Length:

-

Customer's Choice

-

Place Of Origin:

-

China,Shandong

-

Engineering Solution Capability:

-

graphic design, 3D model design, total solution for projects

Quick Details

-

Project Solution Capability:

-

graphic design, total solution for projects, Cross Categories Consolidation, Others

-

Application:

-

Apartment

-

Design Style:

-

Modern

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

SH

-

Model Number:

-

152

-

Product name:

-

Polyurethane Foam Sandwich Panel

-

Keyword:

-

Pu Sandwich Pane

-

MOQ:

-

1 Square Meters

-

Thickness:

-

50/75/100/150/200mm

-

Length:

-

Customer's Choice

-

Place Of Origin:

-

China,Shandong

-

Engineering Solution Capability:

-

graphic design, 3D model design, total solution for projects

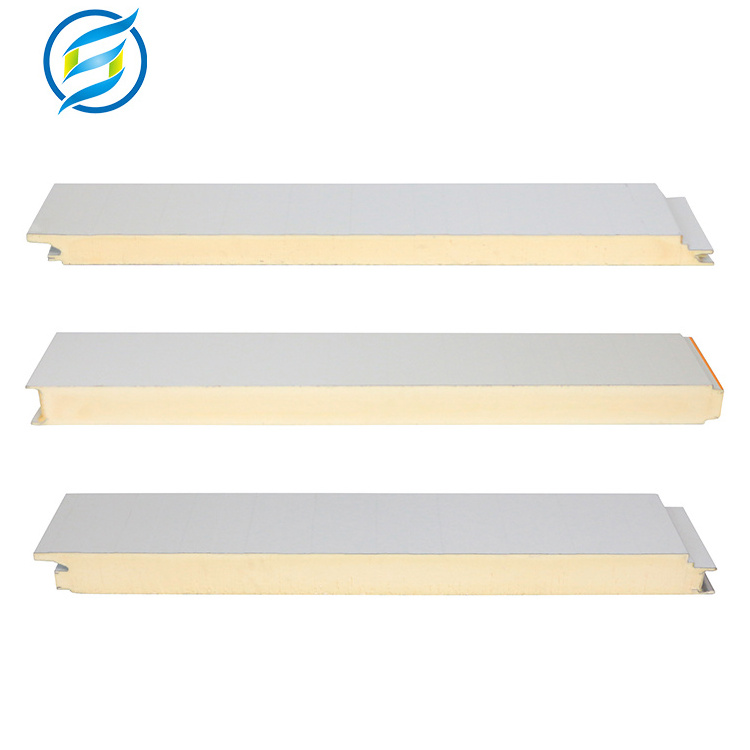

warehouse wall insulated panels easy installation wall polyurethane sandwich panels for exterior wall

Product Description

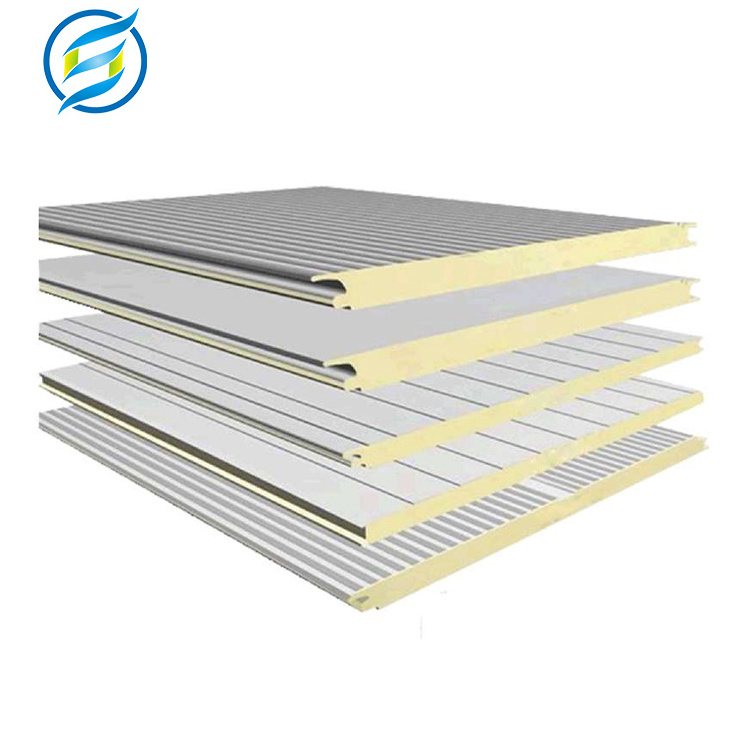

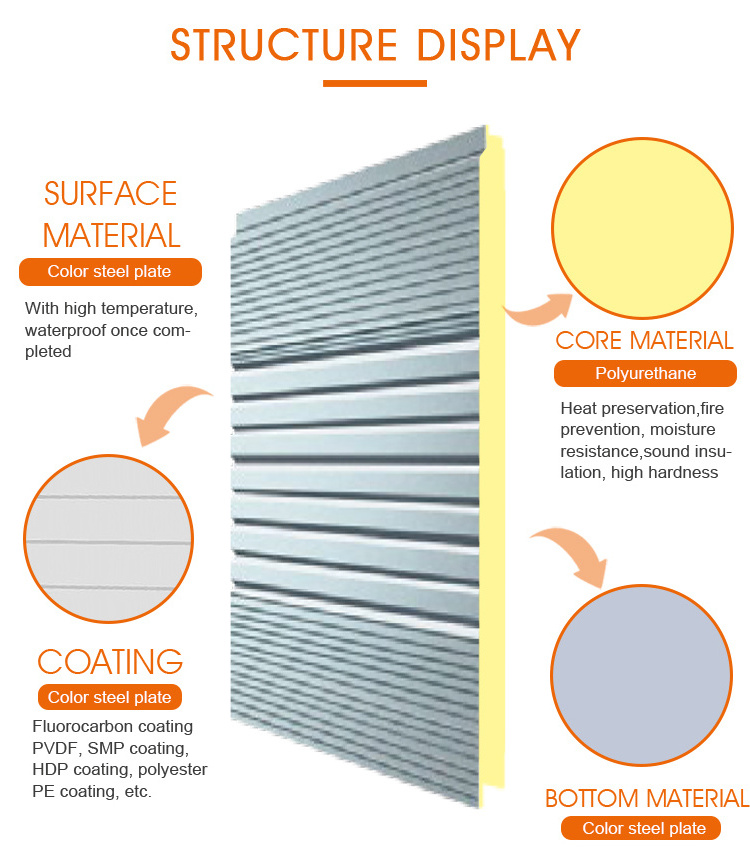

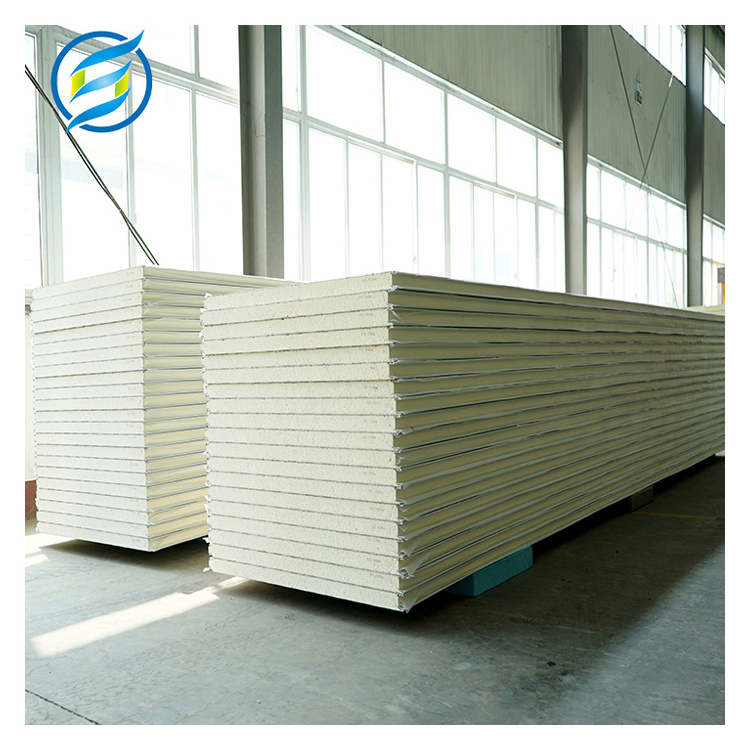

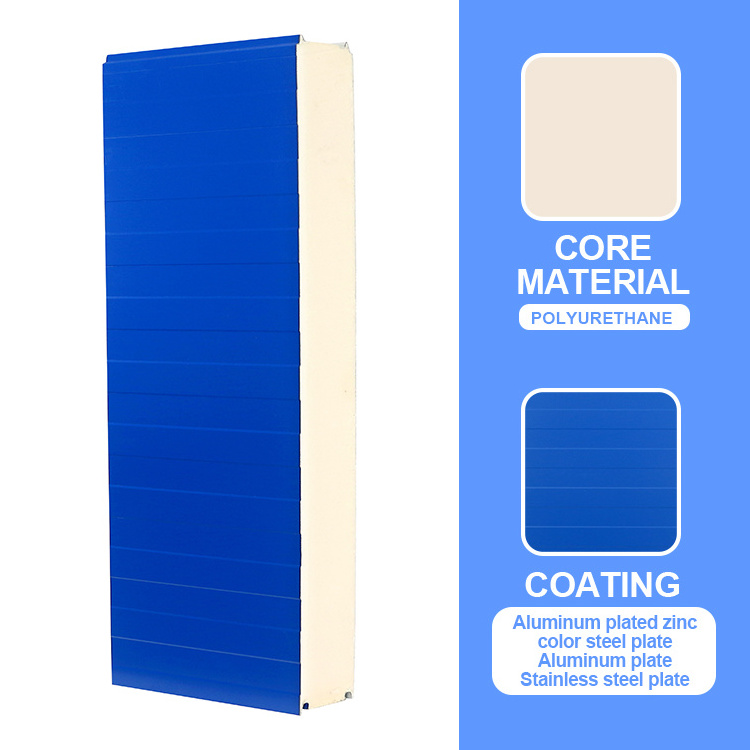

Polyurethane sandwich panel is a composite panel made of high quality color coated steel sheet, stainless steel sheet, galvanized steel sheet, etc., with polyurethane raw material as the core material, which is cured by high temperature foaming. Polyurethane sandwich panel adopts the world's advanced six-component online automatic operation mixing and pouring technology, which can complete the mixing process of social batching center or factory at one time online, and can be adjusted online at will according to the temperature, thus producing distinctive high-strength, energy-saving and green building panels.

|

Parameter Description

|

|

|

|

Product Name

|

Polyurethane Sandwich Composite Panel

|

|

|

Thickness

|

50/75/100/120/150/200mm

|

|

|

Density

|

≥38(kg/m3)

|

|

|

Heat Transfer Coefficient

|

0.45W/(m2.k)

|

|

|

Thermal Conductivity

|

0.024W/(m.k)

|

|

|

Oxygen Index

|

28%

|

|

|

Water Absorption Rate

|

3

|

|

|

Combustion Performance

|

B1

|

|

|

Main Application Occasions

|

Wall /Roof

|

|

Product Details

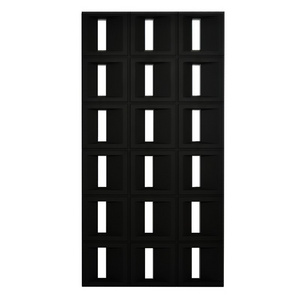

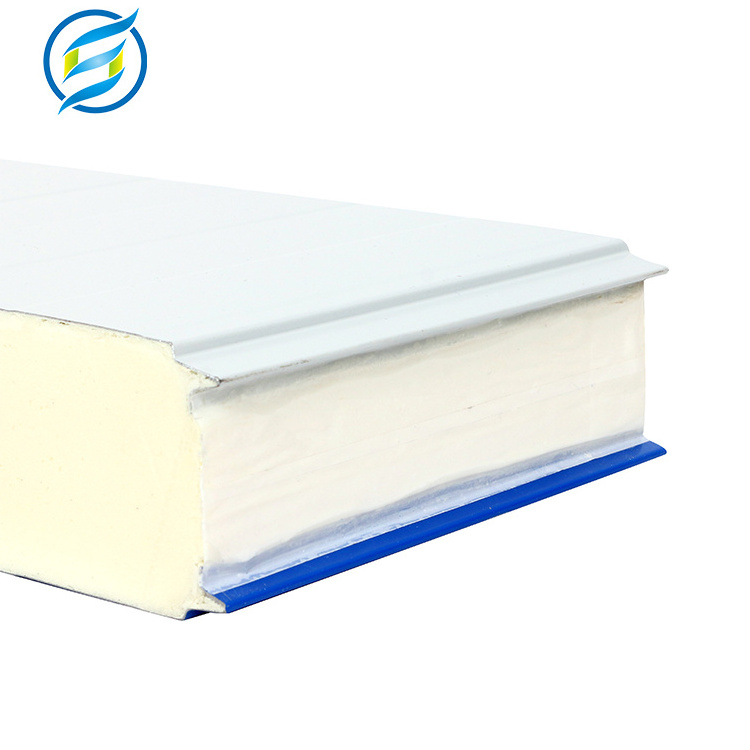

Performance description - Adopt concealed nail type connection, horizontal and vertical placement are available, with tight insertion and no direct heat transfer by nailing. The screws are hidden under the board to prevent rust and corrosion, and to ensure the overall beautiful effect. Reasonable mechanical design of the connection, balanced force, stronger resistance to negative wind pressure.

|

Sheet name

|

Polyurethane wall panel

|

|

Effective lap (mm)

|

1000mm

|

|

Plate thickness (mm)

|

50/75/100/120/150/200

|

|

Color plate thickness (mm)

|

0.4-0.8

|

|

Optional panels

|

Color coated steel, stainless steel, galvanized steel

|

|

Regular colors

|

White gray, large wall gray, dark blue

|

|

Plate effect

|

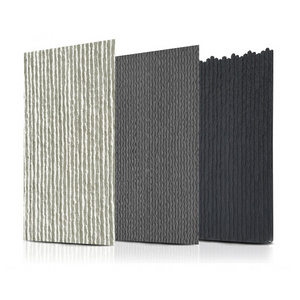

flat, embossed, small ripples, pressure ribs

|

Polyurethane sandwich panel, also called leak-proof sandwich roof panel, polyurethane rigid foam insulation panel, polyurethane composite panel, PU panel, is made of two layers of high-quality colored steel plates with polyurethane foam sandwiched between them. Its surface metal plate is made of colorful aluminized zinc-plated steel plate, which has good anti-corrosion, anti-rust and weathering performance; the core material polyurethane is the best material for heat insulation and thermal insulation recognized in the world today.

Advantages of Sandwich Panel

|

Advantages of the sandwich panels

|

|

|

|

|

||||

|

Efficient thermal insulation

|

Polyurethane composite sandwich panels have the lowest thermal conductivity (≤0.024) among organic thermal insulation materials,

and a 5cm-thick polyurethane composite panel is equivalent to a 1m-thick concrete thermal insulation effect. Polyurethane composite board is an ideal thermal insulation product to achieve the goal of building energy saving of 75%. |

|

|

|

||||

|

Super flame retardant

|

The polyurethane composite board will not burn through after 1000 ℃ flame for 30 minutes.

|

|

|

|

||||

|

Durable weather resistance

|

After more than 6 months of weather resistance test, the performance of the polyurethane composite board is stable and can have

the same life as the building. |

|

|

|

||||

|

Good shape stability

|

The compressive strength of the polyurethane composite board reaches more than 200kp, and the board has good temperature

resistance and no deformation. |

|

|

|

||||

|

Low carbon and environmental protection

|

Polyurethane composite panels use bio-based raw materials, fluorine-free foaming, and do not use harmful substances that are

prohibited or restricted by the state, and are environmentally friendly. |

|

|

|

||||

|

water proof

|

fire proof

|

|

The good self-structure and compact. concave-convex plug installation method avoid the structural damage caused by the freezing ,thawing freezing, thawing and drying cycles, and eliminate water-seepage.

|

The surface of the board is a metal layer made by a special process. the inner core is a hard high -density polyurethane foam

insulation layer treated by flame retardant .The layer is made of the fire proof and moisture proof. |

|

|

|

|

|

|

Production Workshop

product application

Polyurethane sandwich panels are widely used in:

Large industrial plants, cold storages, garages, mobile homes, airports, power plants, gymnasiums, shopping centers, villas,hospitals, strata and high-rise office buildings.

Due to their excellent thermal and thermal insulation properties, they are mainly used in roofs and walls of industrial and civil buildings.

Large industrial plants, cold storages, garages, mobile homes, airports, power plants, gymnasiums, shopping centers, villas,hospitals, strata and high-rise office buildings.

Due to their excellent thermal and thermal insulation properties, they are mainly used in roofs and walls of industrial and civil buildings.

Hot Searches