- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, Other, 400*200*200 mm, 230*220*115 mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

SHIYUE

-

Voltage:

-

Local Voltage

-

Dimension(L*W*H):

-

2260x1500x2380mm

-

Weight (KG):

-

5500 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Weight:

-

6000kgs

-

Molding cycle:

-

10-12s

-

Color:

-

according to your needs

-

Hydraulic pressure:

-

25-32.5mpa

-

Products:

-

bricks,blocks,paving blocks and so on

-

workers:

-

2-3

-

motor brand:

-

according to your needs

-

Raw material:

-

clay,soil,and concrete,cement and so on

Quick Details

-

Type:

-

Hollow Block Making Machine, Paving Block Making Machine, Interlock Block Making Machine, Curbstone Block Machine, Other, Autoclaved aerated concrete block (AAC)

-

Brick Raw Material:

-

CONCRETE

-

Production Capacity (Pieces/8 hours):

-

Other, 4480 pcs/8hours, 2500 pcs/8hours, 3400 pcs/8hours, 1920 pcs/8hours, 5760 pcs/8hours, 1500 pcs/8hours, 1280 pcs/8hours, 3000 pcs/8hours, 12000 pcs/8hours, 3200 pcs/8hours, 2560 pcs/8hours, 1000 pcs/8hours, 800 pcs/8hours, 20000 Pieces/day

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, Other, 400*200*200 mm, 230*220*115 mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

SHIYUE

-

Voltage:

-

Local Voltage

-

Dimension(L*W*H):

-

2260x1500x2380mm

-

Weight (KG):

-

5500 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Weight:

-

6000kgs

-

Molding cycle:

-

10-12s

-

Color:

-

according to your needs

-

Hydraulic pressure:

-

25-32.5mpa

-

Products:

-

bricks,blocks,paving blocks and so on

-

workers:

-

2-3

-

motor brand:

-

according to your needs

-

Raw material:

-

clay,soil,and concrete,cement and so on

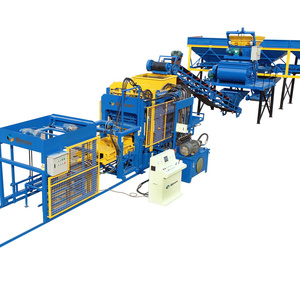

MARCH EXPO QT6-15 Soil Brick Making Machine Price Hollow Block Making Machine interlocking brick machine

Specifications

1.Automatic block making machine,it can save your worker cost

2.Lower investment

3.CE/SGS/ISO9001

4.can make hollow blocks,solid blocks,

5.it is good quality in hot place

6.Other models

Advantages

1.larger productivity

2.Perfect after-sale service network

3.Convenient to operate and maintain

4.Changing the former one-time-vibration into twice-vibrations of molding core

5.Low investment and high profits

6.Durable and long life

7. Produce different kinds of block according to change the mold

8.Save manpower

9.Convenient to operate and maintain

10.Domestic top brand

Main parameters

|

Main Technical Specifications |

|

|

Dimension |

7350*1780*2950mm |

|

Rated pressure |

16MPa |

|

Main vibration |

platform |

|

Vibration frequency |

4600r /min |

|

Pallet Size |

880*700mm |

|

Molding Cycle |

15-20(s) |

|

Overall power |

30.5KW |

|

Raw Materials |

crushed stone, sand, cement, dust and coal fly ash, cinder, slag, gangue, gravel, perlite, and other industrial wastes. |

|

Applied Products |

concrete blocks, solid/hollow/cellular masonry products, paving stones with or without face mix, garden and landscaping products, slabs, edgers, kerbstones, grass blocks, slope blocks, interlocking blocks, etc. |

|

Applied Fields |

widely used in buildings, road pavers, squares, gardens, landscaping, city constructions, etc. |

Different sides of the machine

Capacity

The machine can make many kinds of blocks only by changing the molds

|

Item |

Specification size |

Quantity per mold |

Cycle mouding |

Per hour |

Per day |

|

Hollow brick |

400*200*200 |

6pcs |

16-20s |

1080pcs |

8640pcs/day |

|

Porous brick |

240*115*90 |

14pcs |

15-18s |

2800pcs |

22400pcs/day |

|

Standard brick |

240*115*53 |

30pcs |

14-17s |

6800pcs |

54400pcs/day |

Delivery

1. The whole brick machine production line equipment is mainly the full container sea shipping,

2. Brick machine equipments finish manufacturing and testing, next to clean up, and then do another paint protection,

3. Before shipment to use plastic film winding, wrapped the entire brick machine in case of water or moisture,

4. Then load brick machines into the container by forklift,

5. During loading to tighten the machine with reinforcement ring in container, so as to avoid the damage by transport bumps on the brick machine.