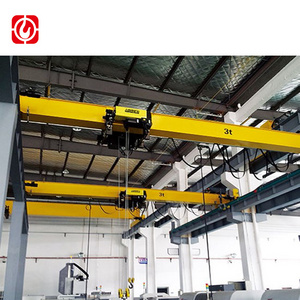

It adopts the latest FEM1001 standard of the European Material Handling Society, which can be certified by DIN, ISO, BS, CMAA, CE

and other major international standards.

In the production process, we have actually applied 37 international industry standards such as DIN18800, BLATT7, DIN15018,

BLATT2, DIN15434, VDE0580, DIN15431, etc.