- Product Details

- {{item.text}}

Quick Details

-

CaO Content (%):

-

customizable

-

CrO Content (%):

-

customizable

-

SiC Content (%):

-

customizable

-

Place of Origin:

-

Henan, China

-

Model Number:

-

Magnesia Zirconia Brick

-

Brand Name:

-

Rongsheng

-

Product name:

-

magnesia zirconium refractory brick

-

Apparent porosity:

-

≤23%

-

Bulk Density(kg/m3):

-

2.0-2.5g/cm3

-

Cold Crushing Strength(MPa):

-

40~70MPa

-

Keyword:

-

magnesia zirconia brick

-

Application:

-

Blast Furnace, Glass Kiln, Cement Kiln

-

Refractoriness under Load (0.2MPa):

-

Min 1420

-

Color:

-

Yellow

-

Certificate:

-

ISO9001

-

Sample:

-

Provide

Quick Details

-

SiO2 Content (%):

-

customizable

-

Al2O3 Content (%):

-

customizable

-

MgO Content (%):

-

70-80%

-

CaO Content (%):

-

customizable

-

CrO Content (%):

-

customizable

-

SiC Content (%):

-

customizable

-

Place of Origin:

-

Henan, China

-

Model Number:

-

Magnesia Zirconia Brick

-

Brand Name:

-

Rongsheng

-

Product name:

-

magnesia zirconium refractory brick

-

Apparent porosity:

-

≤23%

-

Bulk Density(kg/m3):

-

2.0-2.5g/cm3

-

Cold Crushing Strength(MPa):

-

40~70MPa

-

Keyword:

-

magnesia zirconia brick

-

Application:

-

Blast Furnace, Glass Kiln, Cement Kiln

-

Refractoriness under Load (0.2MPa):

-

Min 1420

-

Color:

-

Yellow

-

Certificate:

-

ISO9001

-

Sample:

-

Provide

Product Description

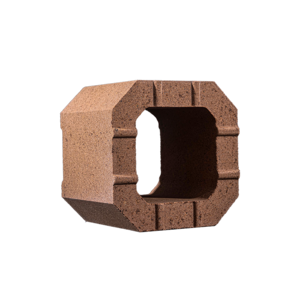

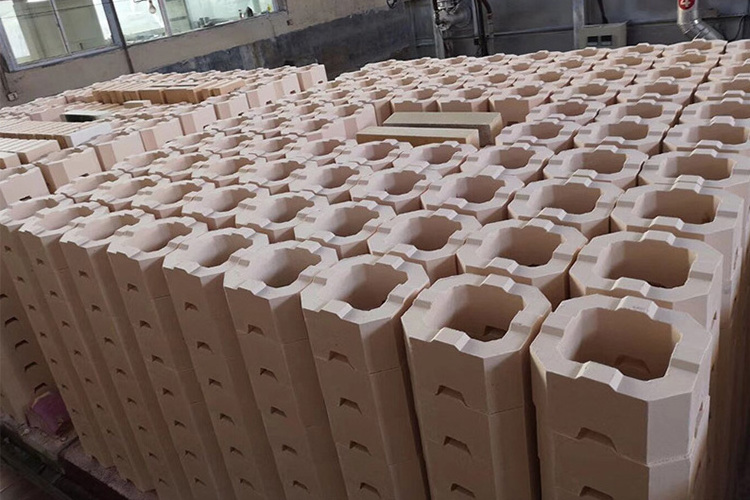

Magnesia zirconia bricks Product Introduction:

Magnesia zirconia bricks are made of high-purity fused magnesia and synthetic magnesia-zirconium sand as raw materials. After high-pressure molding and high-temperature firing, they have excellent corrosion resistance to alkali metals, oxides and sulfides.

Magnesia zirconia bricks Features:

1.Excellent corrosion resistance.

2.High strength.

3.Good stability.

4.Good slag resistance.

Dimensions of Magnesia Zirconia Brick:

The standard size of it is 230*114*65mm; and 230*114*76mm, 230*114*32mm, etc are also common used. Except for the common sizes, some special shapes could be customized according to the customers' requirements

Product Application

Magnesia Zirconia Brick Application:

Magnesia zirconia bricks are widely used in glass melting furnaces, regenerators, cement kilns, steelmaking electric furnaces and non-ferrous metal smelting.

Specification

|

Item

|

|

RSMZ8

|

RSMZ10

|

RSMZ13

|

|

|

Chemical composition (%)

|

MgO ≥

|

80

|

75

|

70

|

|

|

|

ZrO2 ≤

|

8

|

10

|

13

|

|

|

Apparent Porosity(%) ≤

|

|

19

|

18

|

18

|

|

|

Bulk Density (g/cm3) ≥

|

|

2.95

|

3.00

|

3.05

|

|

|

Cold Crushing Strength (Mpa) ≥

|

|

50

|

45

|

40

|

|

|

0.2Mpa Refractoriness Under Load ( ºC)

|

|

1600

|

1550

|

1600

|

|

|

Thermal Shock Resistance 950 ºC-air cold (cycles) ≥

|

|

10

|

10

|

10

|

|

Our Advantages

Rongsheng Refractory has professional sales and after-sale service team who provide customers all-around service about product application, construction installation and operation technology training etc.

Packing & Delivery

Wooden pallets with plastic film or according to your request.

Hot Searches