- Product Details

- {{item.text}}

Quick Details

-

Applicable Industries:

-

Working platform size

-

Usage:

-

Table/dinner ware Polishing

-

Size:

-

1600MM*1400MM*1200MM

-

Weight:

-

800KG

-

KEY:

-

marble polishing machine

-

After-sales Service Provided:

-

Video technical support

-

After Warranty Service:

-

Video technical support

-

Local Service Location:

-

None

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Yi-Liang

-

Weight (KG):

-

1000

-

Applicable Industries:

-

Working platform size

-

Usage:

-

Table/dinner ware Polishing

-

Size:

-

1600MM*1400MM*1200MM

-

Weight:

-

800KG

-

KEY:

-

marble polishing machine

-

After-sales Service Provided:

-

Video technical support

-

After Warranty Service:

-

Video technical support

-

Local Service Location:

-

None

Product Details

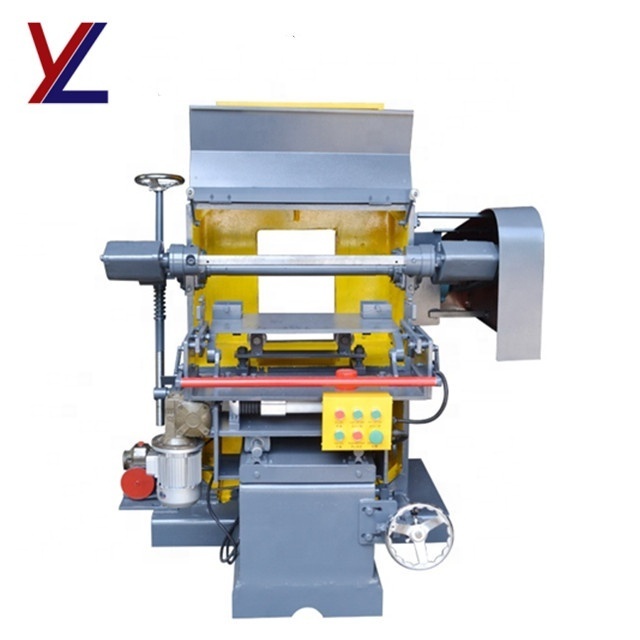

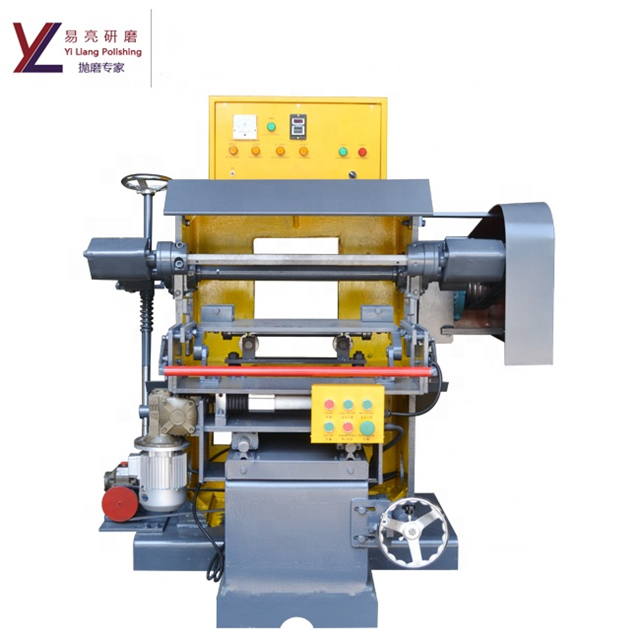

Single shaft wire drawing machine polishing machine motor for spoon metal surface as door hinges to be clear and mirror finish

suitable for door hinges,spoon handles,sides of spoons,sides of table knives,forks,ordinary hardware flat products,ets

Introduction

1. For flat polishing and plane burnishing of stainless steel plate,black metal,non-ferrous metal,nonmetallic work piece, copper plate, aluminium plate,polishing the rags, edge, oxide coating, rusts generated at the process of punching, die -casting, and casting the parts.Matte finish and mirror finish available

2. Electromagnet device can be installed to simplify manipulate and ensure the polishing quality as the size of work piece, Only for metal products. For thin stainless steel, aluminium, copper work pieces, special holder can be installed.

3. Easy manipulated and fixed with mechanical drive and with imported original electric cabinet 4. Workbench has slightly swing from side to side, in order to reduce the bad effect caused by wiredrawing.

5. Grinding time can be adjusted, makes the milling time is more flexible.

Basic parameter of machine

|

Specification |

drive

|

Crosswise swing

|

move in and out

|

Opening and Closing

|

|||

|

Motor Power

|

7.5KW-4*1

|

250W-4*1

|

370W-4*1

|

tapered motor 0.4KW-4*1

|

|||

|

Reduction Box

|

|

WPA40-20

|

Wd47-50

|

WD47-30

|

|||

|

voltage

|

380V,50HZ

|

|

|

|

|||

|

Spindle Speed

|

1800-2200 r/min

|

|

|

|

|||

|

Grind time

|

0-3 minutes

|

|

|

|

|||

|

Machine Size

|

1500MM*1500MM*1300MM(L*W*H)

|

|

|

|

|||

|

Weight

|

1250KG

|

|

|

|

|||

|

Spindle Length

|

600MM

|

|

|

|

|||

|

Grind area

|

600MM*40MM(L*W)(allowed custom-made as your request)

|

|

|

|

|||

|

Match Polishing Material

|

Abrasives as Cloth/cotton, sisal/fibre voltage, nylon voltage,flap wheel and act.

|

|

|

|

|||

Main Motor Power:

1. Power: 5.5KW /7.5KW. (5.5kw is suitable for small size plane work piece polishing; 7.5KW is suitable for the big size flat work piece polishing. If you have any confused to choice the right power, please kindly contact us. )

2.Voltage: 380V, 3 phase. (Noted: The voltage is measured by industry voltage. We accept custom-made to fix industrial voltage for diffrent countries needed)

3.Frequency: 50 Hz

(Remark : All the motor we used is high quality and new . It is long lifes with the right voltage.)

Power Rate Rotate Speed(RPM)

Main Motor 4 Poles, 5.5/7.5KW 1400

Sway Controlling Motor 4 Poles, 250W 1400

In/Out Controlling Motor 6 Poles, 370W 980

Open/Close Controlling Motor 4 Poles, 400W 400

product shows

Advantages:

1.Easy adjusting height of polishing shaft by regular adjusting rod. Clockwise adjust for higher shaft, reduce polishing pressure; anticlockwise adjust for lower shaft, fortify polishing pressure. Note: Adjust slowly in case of not enough pressure or too much pressure.

2.Easy adjustment. (Only with 6 control button to finish all the operate step! And it can adjust the grinding time according your products. )

3.With high efficient production .

4.It will spend from 30 seconds to 3 minutes to finish one polishing step at one time . More flexible for spoon flat (before shaped) polishing.

Consumables

Abrasives as Cloth/cotton, sisal/fibre voltage, nylon voltage,flap wheel and act.

You can change different polish wheels according your traditional polishing procedure,

To get a higher production,3 or more machines fixed for every specific step is needed.

Why Choose Us

company information

Guangzhou Yi-Liang Limited Company established in 2008, we are qualified manufacturer and wholesaler of polishing, grinding consumables, polishing materials(buffing wheel, polishing wax, sanding belt, abrasives) and machinery for metal ware, automobile and traffic equipment, furniture, musical instrument, stainless steel products, ceramics and electronic products.Our products have been sold to about 30 countries, and customers all give high evaluation.

Our company has years of polishing experience and technique, involved in Dinner ware Polishing Production Line, Hinge production line, Alloy and hardware polishing production Line, Cast tube machinery, Furniture Polishing, etc.

1.Experience: With 20 years polishing experience and technique, involved in Dinner ware Polishing Production Line, Hinge production line, Alloy and hardware polishing production Line, Cast tube machinery, Furniture Polishing, etc.

2.Customization: All specification can be customized as your request.

3.Belief: Customers grow with us & maximizing your productivity at lowest cost.

4.Certification: Verified By Onsite Checked of Alibaba.com

Hot Searches