- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Deheng

-

Power:

-

6.5KW

-

Dimension(L*W*H):

-

5850*1300*2050mm, 2800x1100x1800mm

-

Weight:

-

1300KG

-

Certification:

-

CE, CE

-

After Warranty Service:

-

Spare parts, Video technical support

-

Power(W):

-

1.5kw

-

Making Speed:

-

80-150pcs/min

Quick Details

-

Production Capacity:

-

100%, 80-150pcs/min

-

Voltage:

-

220V, 220V, 220V 50HZ

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Deheng

-

Power:

-

6.5KW

-

Dimension(L*W*H):

-

5850*1300*2050mm, 2800x1100x1800mm

-

Weight:

-

1300KG

-

Certification:

-

CE, CE

-

After Warranty Service:

-

Spare parts, Video technical support

-

Power(W):

-

1.5kw

-

Making Speed:

-

80-150pcs/min

Feature

1. It adopts the microcomputer contact screen to control, three-phase mixing motor to pull material; and producing piece number can be set up freely.

2. It is suitable for all kinds of molds, easy operation.

3. It is suitable for producing HDPE and LDPE film into the glove, which widely used in medical, restaurant, and food filed for its convenience and healthy.

Parameter

|

Glove mould size |

36.5×39cm |

|

Glove Making Speed |

50-220Pcs/Min/Layer, total 440pcs/min |

|

Film roll unwinding device

|

with mechanical shaft Tension Controller: 2.5KG magnetic barker with manual controller |

|

Unwinding motor |

Unwinding motor: 0.55KW, with 1.1KW inverter Controlling: main computer controlling. |

|

Main driver |

Structure: crank rocker push-pull structure Drive: A.C motor with inverter controlled, 1.5 KW, 6 grade Controlling: main computer controlling. |

|

Front Traction motor |

Structure: Friction type, Drive: Step motor Transmission: M-type synchronous belt wheel drive, Control form: step motor driver Detection method: photocell combined with proximity switch |

|

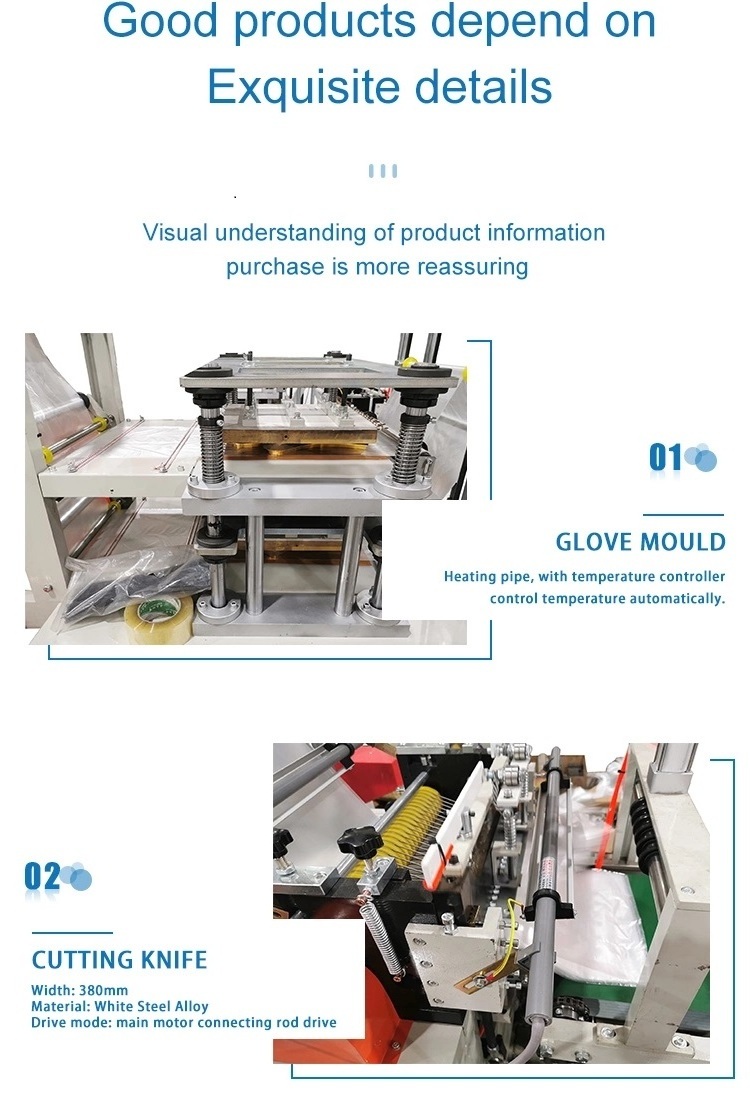

Glove mould |

Raw material: Cast copper Heating: heating pipe, with temperature controller, control temperature automatically. |

|

Cutting knife |

Width: 380mm Material: White Steel Alloy Drive mode: main motor connecting rod drive |

|

Electric Cabinet |

Main Computer: Touch screen microcomputer- Contactor, swift |

|

Automatic waste edge tearing device |

Waste edge tear model: tearing by batches, and delivery out by batches Controlling: PLC and pneumatic cylinder |

|

Other |

Tracking photocell: 1 set Static Eliminator: dry type, elimination bar * 2, elimination device * 1 Conveyor belt: 1 set |

|

Weight |

1300KG |

|

Over Size (L×W×H) |

2600×1000×1400mm |