- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

haokunda

-

Model Number:

-

AR500 AR400 AR450 AR550

-

Width:

-

1500mm-3000mm

-

Length:

-

as customer requirement

-

Product Name:

-

Wear Resistant Steel Plate

-

Keyword:

-

Ms Plate

-

MOQ:

-

1 Ton

-

Material:

-

AR500 AR400 AR450 AR550

-

Packages:

-

Customizable packaging

-

Shape:

-

Flat.sheet

-

Port:

-

Qingdao Port

-

Name:

-

AR500 AR400 AR450 AR550

-

Payment term:

-

T/T

-

Surface:

-

Smooth

Quick Details

-

Grade:

-

AR500 AR400 AR450 AR550

-

Tolerance:

-

±1%

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

haokunda

-

Model Number:

-

AR500 AR400 AR450 AR550

-

Width:

-

1500mm-3000mm

-

Length:

-

as customer requirement

-

Product Name:

-

Wear Resistant Steel Plate

-

Keyword:

-

Ms Plate

-

MOQ:

-

1 Ton

-

Material:

-

AR500 AR400 AR450 AR550

-

Packages:

-

Customizable packaging

-

Shape:

-

Flat.sheet

-

Port:

-

Qingdao Port

-

Name:

-

AR500 AR400 AR450 AR550

-

Payment term:

-

T/T

-

Surface:

-

Smooth

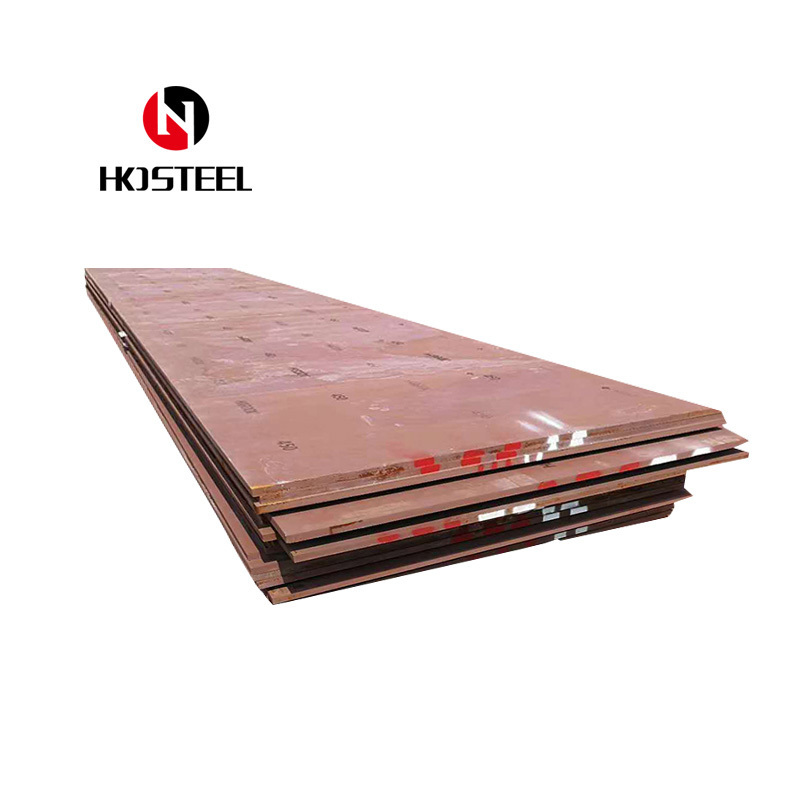

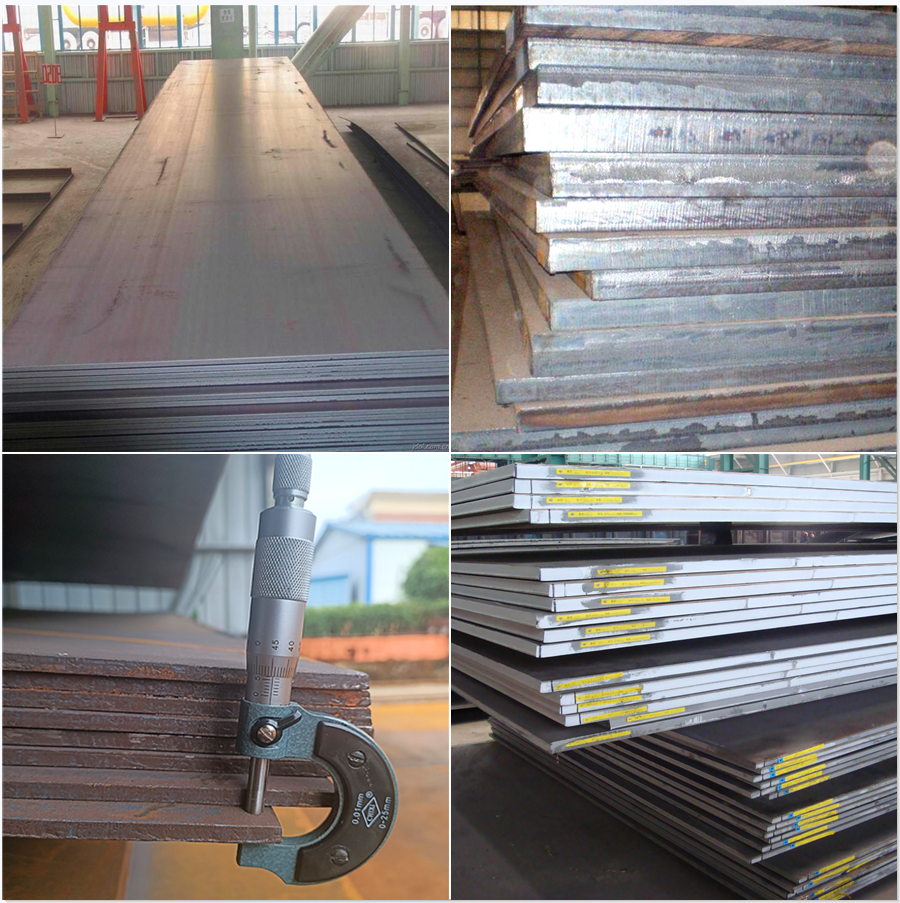

Product Introduction

Welding process is the use of the most advanced open arc welding welding process, the various effects of this process on the erformance of a very small base , and wear to maximize play. Composite wear plate is ordinary steel (Q235 (A3) or heat-resistant steel (15CrMo, 12Cr! MoV , etc. ) , stainless steel plate formed on the entire volume fraction of more than 50% Cr7C3 carbide based wear layer , which with high wear resistance , impact resistance, deformable and welding performance, like steel , like direct texturing , cutting and drilling and other processing sectors , processed into mining engineering components to meet the wear and put into use . wear-resistant material with many compared wear-resistant composite plate has its irreplaceable notable features.

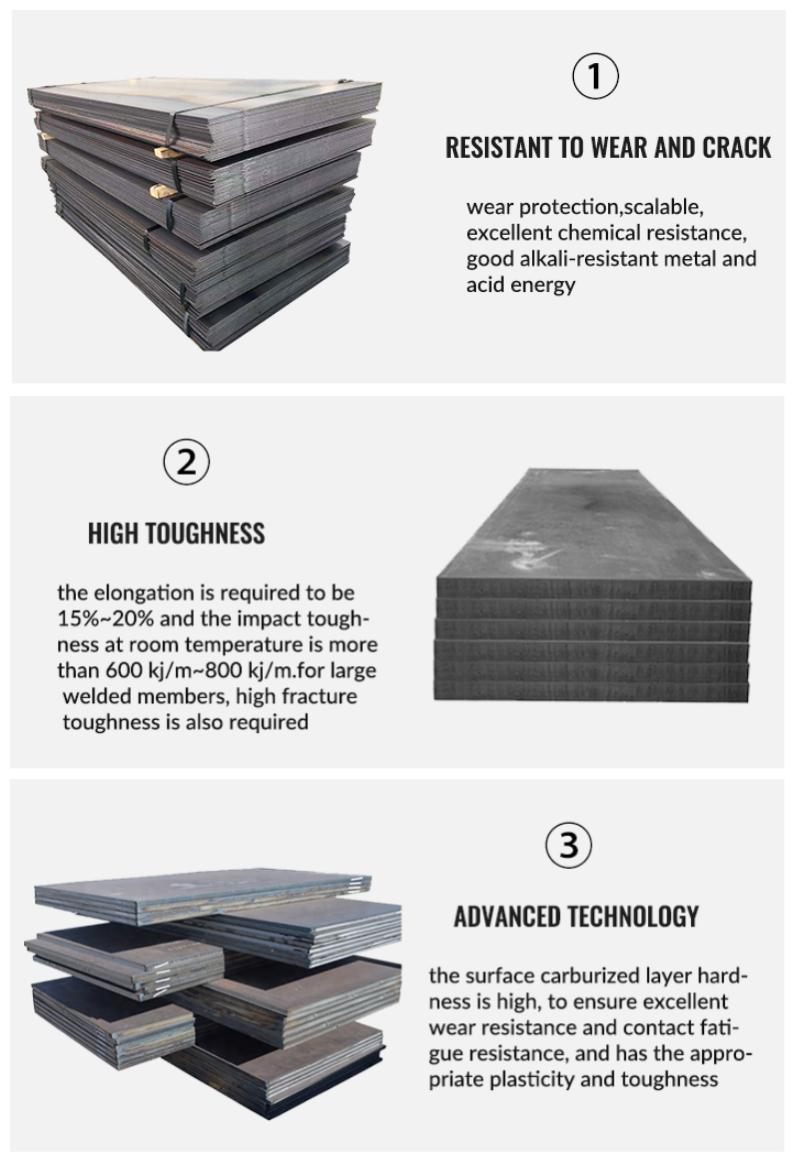

1. Excellent wear resistance

The chemical composition of the alloy wear-resistant layer has a carbon content of 4 to 5% and a chromium content of 25 to 30%. The volume fraction of Cr7C3 carbides in the metallographic structure is more than 50%. The macroscopic hardness is HRC56 to 62. The hardness is HV1400~1800. Because carbides are distributed perpendicularly in the direction of wear, even when compared with cast alloys of the same composition and hardness, the wear resistance is more than doubled. The comparison with the wear resistance of several typical materials is as follows:

(1) With low carbon steel; 20~25:1

(2) With as-cast high chromium cast iron; 1.5~2.5:1

2. Good impact resistance

The base plate of the wear-resistant composite steel plate is low carbon steel or low alloy. Tough materials such as stainless steel reflect the superiority of bimetal. The wear-resistant layer resists the wear of the wear medium, and the substrate bears the load of the medium, so it has good impact resistance. It can withstand the impact and wear of the high drop hopper in the material conveying system.

3. Good heat resistance

The alloy wear-resistant layer is recommended to be used under ≤600℃. If vanadium, molybdenum and other alloys are added to the alloy wear-resistant layer, it can withstand high temperature wear of ≤800℃. The recommended operating temperature is as follows: Ordinary carbon steel base plate is recommended to be used under the working condition of not higher than 380℃; Low-alloy heat-resistant steel plate (15CrMo, 12Cr1MOV, etc.) substrates are recommended to be used in working conditions not higher than 540℃; The heat-resistant stainless steel substrate is recommended to be used at no higher than 800°C.

4. Good corrosion resistance

The alloy layer of the wear-resistant composite steel plate contains a high percentage of metallic chromium, so it has a certain degree of rust and corrosion resistance. It can be used to prevent coal sticking when used in coal dropping drums and hoppers.

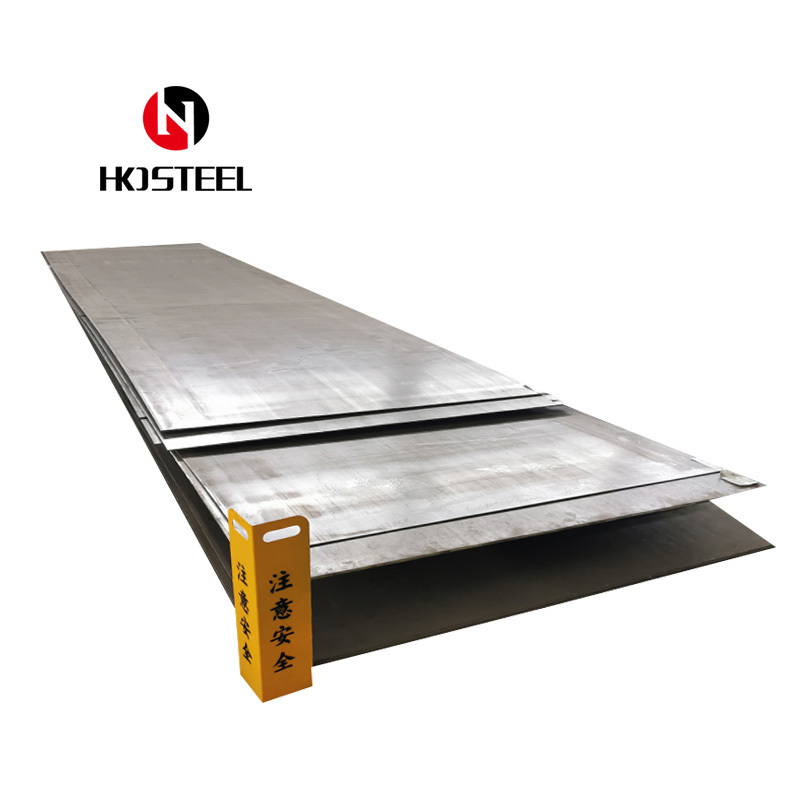

5. Complete varieties and specifications

The wear-resistant steel plate has complete specifications and many varieties, and has become a commercial serialization. The thickness of the wear-resistant alloy layer is 3-20mm. The thickness of the composite steel plate is at least 6mm, and the thickness is not limited. The standard wear-resistant steel plate can be provided with 1200 or 3800×12000mm, and it can also be processed according to the size of the drawings according to user needs. Wear-resistant steel plates are now divided into three types: ordinary type, impact-resistant type and high-temperature type. Ordering high-temperature wear-resistant and impact-resistant composite steel plates should be explained.

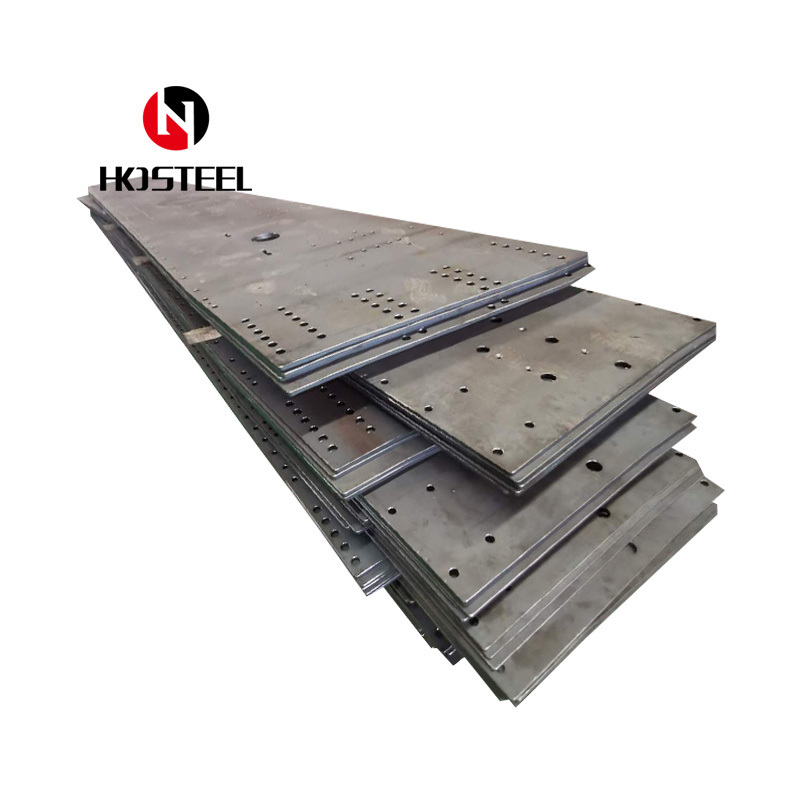

6. Convenient processing performance

The wear-resistant steel plate can be cut, bent or crimped, welded and punched, and it can be processed into various parts that can be processed by ordinary steel plates. The cut wear-resistant steel plates can be tailor-welded into various engineering structural parts or parts.

7. Functions and Features

It can be welded and has good wear resistance.

Our Products

Hot rolled steel coil

Hot rolled steel sheet

Hot rolled steel plate

Customer Photo&Certifications

Customer Feedback

Packing & Delivery

|

Package

|

Wooden pallets,Steel belt packaging or as required

|

|

|

|

|||

|

Lead time

|

Within 10 days after receipt of deposit, special specifications need to be negotiated

|

|

|

|

|||

|

Price terms

|

FOB,CIF,CRF,EXW

|

|

|

|

|||

|

Payment terms

|

T/T,L/C

|

|

|

|

|||

Hot Searches