- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220/380v customized

-

Power:

-

7.5kw

-

Weight:

-

210 KG

-

Dimension(L*W*H):

-

800*380*1200mm

-

Year:

-

2021

-

Function:

-

Ginger Paste Grinding Machine

-

Capacity:

-

300-1200KG/H

-

Power(kw):

-

7.5

-

Feed port diameter:

-

80mm

-

Feeding Hopper volume:

-

8L

-

After Warranty Service:

-

Video technical support, Online support, Field maintenance and repair service

-

Local Service Location:

-

Viet Nam

-

After-sales Service Provided:

-

Field maintenance and repair service

-

Certification:

-

CE

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Longer

-

Type:

-

shallot paste maker

-

Voltage:

-

220/380v customized

-

Power:

-

7.5kw

-

Weight:

-

210 KG

-

Dimension(L*W*H):

-

800*380*1200mm

-

Year:

-

2021

-

Function:

-

Ginger Paste Grinding Machine

-

Capacity:

-

300-1200KG/H

-

Power(kw):

-

7.5

-

Feed port diameter:

-

80mm

-

Feeding Hopper volume:

-

8L

-

After Warranty Service:

-

Video technical support, Online support, Field maintenance and repair service

-

Local Service Location:

-

Viet Nam

-

After-sales Service Provided:

-

Field maintenance and repair service

-

Certification:

-

CE

Product Description

|

Model

|

LG-JMS110

|

|

Capacity

|

300-1200KG/H

|

|

Power(kw)

|

7.5

|

|

Dimension(mm)

|

750*450*1000

|

|

Feed port diameter

|

80mm

|

|

Feeding Hopper volume

|

8L

|

|

Note

|

Data here are for reference only, specific parameters are subject to actual machine.

|

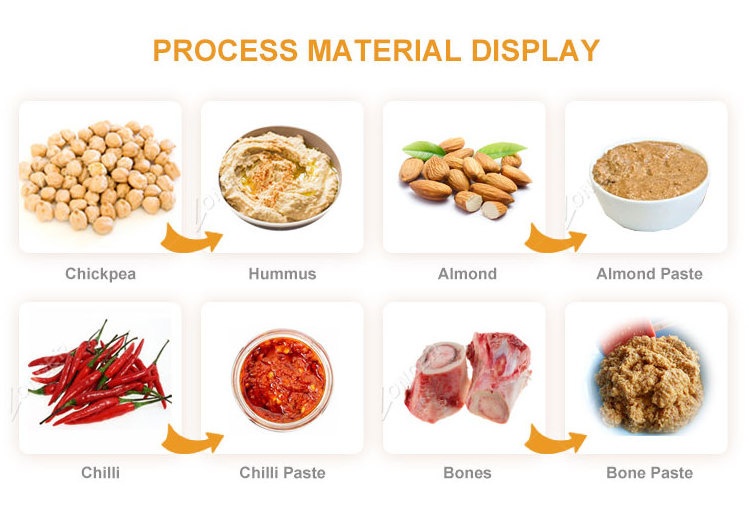

Application of

Ginger Paste Grinding Machine:

It can stir the fresh or bloated capsicum into paste. Meanwhile, it can also grind the garlic, ginger, potato, spinach, onion or lotus root into paste.

Detailed Images

Related Products

Company Introduction

FAQ

Q1. Can I change the material of the stator and rotor?

A1: The material texture is soft. If the acid content is high, the 304 material can be used. It is generally not recommended to change the rotor material.

Q2. How is the discharge temperature?

A2: When grinding nuts, beans, long-term work monomer colloid milling temperature is 70-80 degrees Celsius, double colloid milling temperature is 100 degrees Celsius.

Q3. How to clean the machine?

A3: Clean the machine with water, dry it with a high-pressure air gun, keep it dry in a dry place, check the machine regularly and apply oil on the machine.

Q4. How to grind repeatedly?

A4: The colloid mill grinding nozzle can be changed to the circulating return pipe. The circulating return pipe is provided with a three-way valve. It can be discharged or cycled as needed. All models can be changed. The 80 and 110 return pipes are 25mm in diameter, 130/. 180 return pipe diameter 32mm.

Q5. How often to replace the fixed rotor?

A5: The nut material is generally grind 100-200T, the rotor must be replaced, for other materials, according to the hardness of the material and equipment using frequency.

Q6. How to use the cooling nozzles?

A6: The machine should be used cooling nozzles first, then start to grind material.

Customer Photos

Hot Searches