- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Echo

-

Dimension(L*W*H):

-

16000*3350*3780mm

-

Weight:

-

48000 KG

-

Applicaton:

-

Stone Process

-

Max feeding size:

-

700mm

-

Spare parts supply:

-

avaiable

-

Output size:

-

70-200mm

-

Feeding capacity:

-

180-400t/h

-

Hopper volume:

-

6m³

-

Power:

-

135kw

-

Equipment size:

-

14850*3100*3900

-

Online Service Time:

-

Avaiable

-

Raw material:

-

Iron Ore

Quick Details

-

Application:

-

mining,quarry,aggregate,road construction

-

Capacity(t/h):

-

160-500

-

Place of Origin:

-

Shanghai

-

Brand Name:

-

Echo

-

Dimension(L*W*H):

-

16000*3350*3780mm

-

Weight:

-

48000 KG

-

Applicaton:

-

Stone Process

-

Max feeding size:

-

700mm

-

Spare parts supply:

-

avaiable

-

Output size:

-

70-200mm

-

Feeding capacity:

-

180-400t/h

-

Hopper volume:

-

6m³

-

Power:

-

135kw

-

Equipment size:

-

14850*3100*3900

-

Online Service Time:

-

Avaiable

-

Raw material:

-

Iron Ore

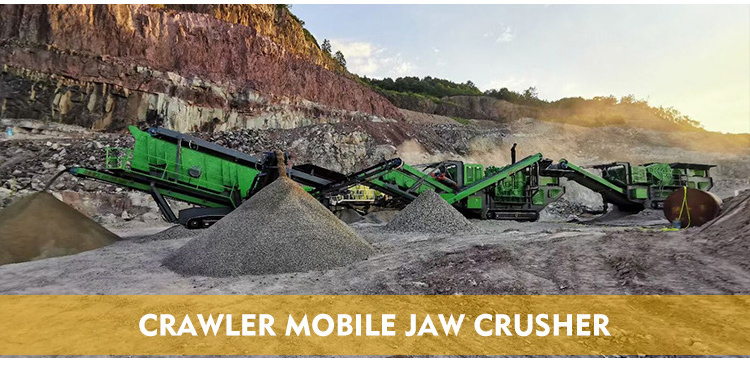

JAW CRUSHER--EC106,EC116

Application: Quarry / Mining / Recycling / Construction and demolition waste / Aggregate / Industry /

Environmental protection

THE APPLICATION OF JAW CRUSHER

With the characteristics of large crushing ratio, uniform product size, simple structure, reliable work, easy maintenance, and economical operating costs, jaw crushers are widely used in mines (limestone, granite, basalt, diabase, andesite, etc.) smelting, building materials, highway, railway, water conservancy and chemical industry and many other sectors, crushing various materials with compressive strength not exceeding 320MPa, is the first choice for primary crushing equipment.

PRODUCT PARAMETER TABLE

Standard configuration: external power supply type.Simple and efficient, high reliability, low equipment maintenance and operating costs.It is equipped with a 250kw engine for petrol and electricity.

Standard configuration: external power supply type.Simple and efficient, high reliability, low equipment maintenance and operating costs.It is equipped with a 250kw engine for petrol and electricity.

| Technical details | Model | EC106 | EC116 |

| Processing capacity (t/h) | 180-400 | 160-500 | |

| Feeding capacity (t/h) | 400 | 450 | |

| Feed opening size (mm) | 1060*750 | 1160*850 | |

| Maximum feeding size | <700 (recommended) | 700 | |

| Hopper volume (m³) | 6 | 8 | |

| discharges size (mm) | 70-200 | 70-200 | |

| Host power (kw) | 110 | 132 | |

| Total power (kw) | 135 | 158 | |

| Iron remover power (kw) | 4 | 6 | |

| Feeding hopper power (kw) | 6 | 8 | |

| Main belt power (kw) | 15 | 20 | |

| Transport | Equipment size (length * width * height)(mm) | 14850*3100*3900 | 16000*3350*3780 |

| Total weight of equipment (t) | 38 | 48 | |

| Option |

*Screening system

*Onboard air compressor *Customized painting *Main conveyor service device *Customized motor brand |

||

Tips:

1. The output of the crushing station is related to the hardness, particle size and discharge particle size of the stone.

2. In view of the continuous update of our products, the specific parameters are subject to the latest update introduction.

Excellent Jaw Crusher: Continuous feeding system, overload protection, to ensure continuous and reliable operation of the equipment; unique cavity design, achieve large crushing ratio, high productivity, and low energy consumption.

Wide Range of Applications: It is widely used in the initial crushing of various hard and strong abrasive rocks and minerals, with wide adaptability.

Easy Maintenance: Comes with walking power, combined with external power supply, easy to maintain, energy saving and environmental protection.

Fast Transition: It’s easy to transport, wireless remote control walking, fast transition; Also can adapt to complex working environments such as mountains and wetlands.