Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V 50hz or as request

-

Dimension(L*W*H):

-

Size

-

Power (kW):

-

200

-

Weight:

-

10

-

Material:

-

PP/PE

-

Capacity:

-

150kg-800kg

-

Power:

-

55kw-132kw

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Inverter:

-

ABB

-

Motor:

-

Siemens

-

name:

-

Plastic pelletizing machine for PE PP Film Pelletizing Recycling Plant

-

The material:

-

pp pe soft film bags and rigid material

-

pelletizer type:

-

water-ring type and noodle type pelletizing

-

feeding material type:

-

agglomerated,side force feeder,dose feeder,verticel force feeder

-

Marketing Type:

-

Ordinary Product

Quick Details

-

Output (kg/h):

-

150 - 1000 kg/h

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Sevenstars

-

Voltage:

-

380V 50hz or as request

-

Dimension(L*W*H):

-

Size

-

Power (kW):

-

200

-

Weight:

-

10

-

Material:

-

PP/PE

-

Capacity:

-

150kg-800kg

-

Power:

-

55kw-132kw

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Inverter:

-

ABB

-

Motor:

-

Siemens

-

name:

-

Plastic pelletizing machine for PE PP Film Pelletizing Recycling Plant

-

The material:

-

pp pe soft film bags and rigid material

-

pelletizer type:

-

water-ring type and noodle type pelletizing

-

feeding material type:

-

agglomerated,side force feeder,dose feeder,verticel force feeder

-

Marketing Type:

-

Ordinary Product

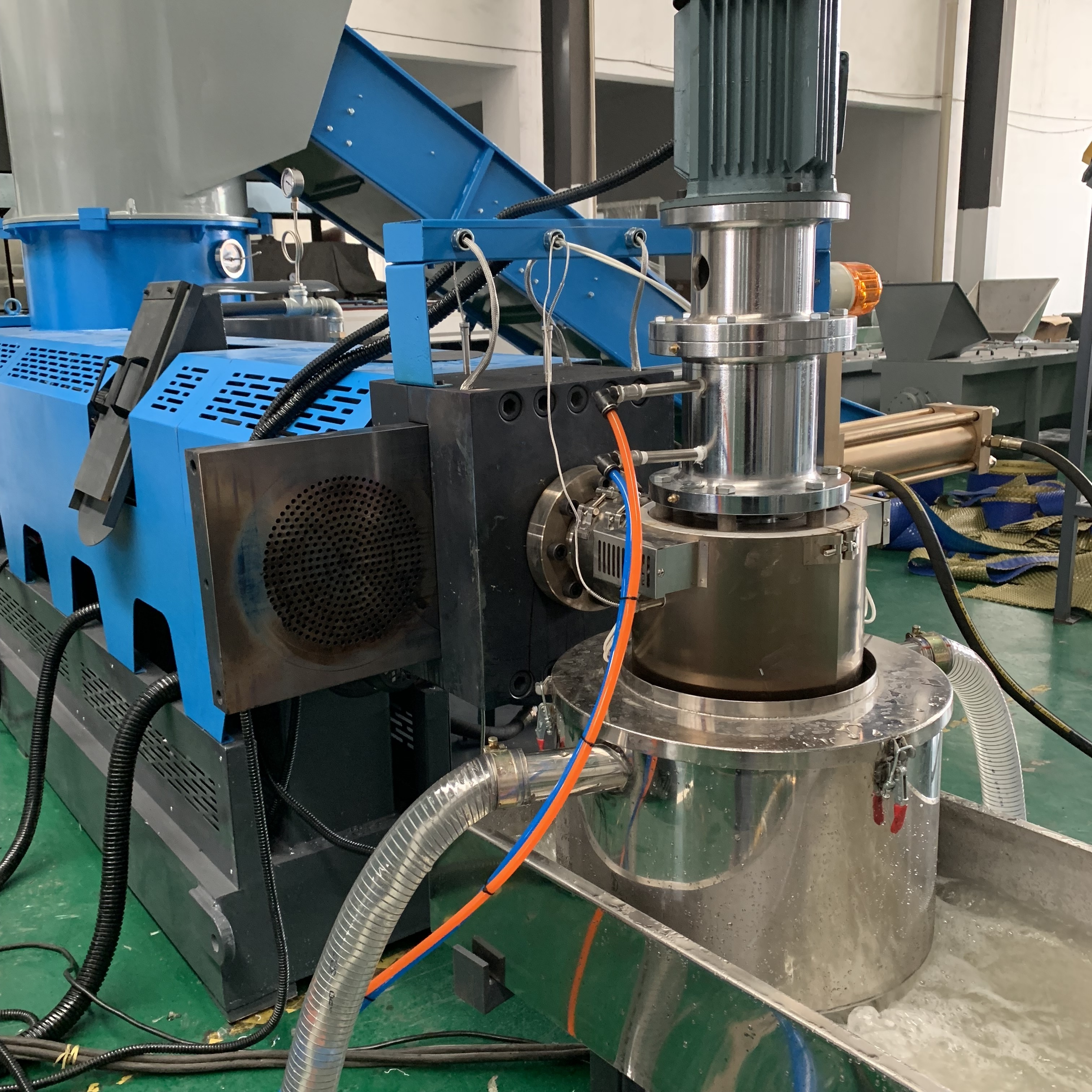

Compactor PE bubble film plastic pelletizing machine / PE film PP bags granulator line

1.Capacity:60kg/h-1000kg/h

2.Type:water-ring pelletizing and stand type

pp pe film pelletizing line/ Plastic film granulator

Usage:

This water-cooling single screw plastic pellet making machine is one stage plastic regenerative pelletizer, which is suitable for many kinds plastic waste materials recycling and making pellet, such as PP, HDPE, LDPE, LLDPE Film EVA and PE foam and clean woven/nonwoven bag materials, etc. The film can be pressed in compressor and then be pelleted,do not need crusher machine.

And also has very developed design, makes sure this machine has a long working life and economical efficiency in using.

Characteristic:

1. Screw and barrel are made of 38CrMoAlA or Bi-metallic, inlet mouth treated with special alloy: very strong and long life.

2. Easy operation: it has automatic constant temperature control and stable performance,After adjusting well, 1 or 2 workers are enough to run this machine, to feed the materials and change pellet receiver.

3. Low cost in using after redesign: now this kind machine is more economic in electric power source and also water. In the long working life of this machine, it can save many sources in energy!

4. High output, long operating life and lower noise: it’s the ideal waste plastics regenerative pelletizer machine for nowadays.

For all this machine we have much experience in it over 10 years,my friend,just send me email,i will give you value suggestion and make the offer exactly based on your requirements.

Agglomerator machine with watering cutter:recycling PE PP film and woven bags.

Agglomerator machine with noodle cutter:recycling PE PP film and woven bags.

Dose feeding pelletizing machine with noodle cutter:recycling agglomerated PE PP and rigid material.

Side force feeder pelletizing machine suitable for the crushed PP PE film and rigid material,such like the film come out from the washing machine.