- Product Details

- {{item.text}}

Quick Details

-

Return Force (kN):

-

240 kN

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

JIANHA BAOFA

-

Voltage:

-

220V/380V/415V

-

Dimension(L*W*H):

-

2000*1000*2300

-

Weight (T):

-

7.5 T

-

Model Number:

-

Y32-200T

-

Motor Power (kw):

-

18.5 kw

-

Marketing Type:

-

New Product

-

Purpose:

-

Metal forming

-

Electrical components:

-

Schneider

-

Power Source:

-

Hydraulic

-

Model:

-

Y32-200TXC

-

Type:

-

4 Columns

-

Color:

-

Customise

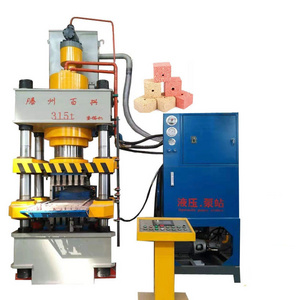

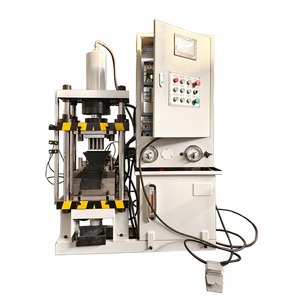

Quick Details

-

Machine Type:

-

Four-column Four-beam Hydraulic Press

-

Slide Stroke (mm):

-

650

-

Ejector Force (kN):

-

2000

-

Return Force (kN):

-

240 kN

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

JIANHA BAOFA

-

Voltage:

-

220V/380V/415V

-

Dimension(L*W*H):

-

2000*1000*2300

-

Weight (T):

-

7.5 T

-

Model Number:

-

Y32-200T

-

Motor Power (kw):

-

18.5 kw

-

Marketing Type:

-

New Product

-

Purpose:

-

Metal forming

-

Electrical components:

-

Schneider

-

Power Source:

-

Hydraulic

-

Model:

-

Y32-200TXC

-

Type:

-

4 Columns

-

Color:

-

Customise

Product Paramenters

|

Technical Parameters

|

|

Y32-200TC

|

Y32-400T

|

Y32-630T

|

|

|

Nominal pressure(KN)

|

|

2000

|

4000

|

6300

|

|

|

System pressure(MPa)

|

|

25

|

25

|

25

|

|

|

Maximum opening height(mm)

|

|

700

|

610

|

1050

|

|

|

Slider stroke(mm)

|

|

650

|

550

|

550

|

|

|

Effective size of workbench(mm)

|

The left anf right sides

|

900

|

780

|

1000

|

|

|

|

The front and rear sides

|

600

|

850

|

1000

|

|

|

Slider speed(mm/s)

|

Ldle stroke

|

170

|

160

|

180

|

|

|

|

Feeding

|

8-20

|

5-15

|

2-15

|

|

|

|

Back tracking

|

130

|

150

|

50-240

|

|

|

Travel of floating die frame (mm)

|

|

150

|

300

|

300

|

|

|

Bin stroke (mm)

|

|

600

|

700

|

|

|

|

Lifting speed of floating die frame (mm/s)

|

|

|

20

|

20-80

|

|

|

Downward speed of floating die frame (mm/s)

|

|

|

24

|

5-35

|

|

|

Floating die frame speed (mm/s)

|

|

25

|

|

|

|

|

Release force of floating mold holder (T)

|

|

80

|

220

|

250T

|

|

|

Distribution speed of oil cylinder (mm)

|

|

|

70-80

|

100-400

|

|

|

Motor power (KW)

|

|

18.5

|

22

|

27*2

|

|

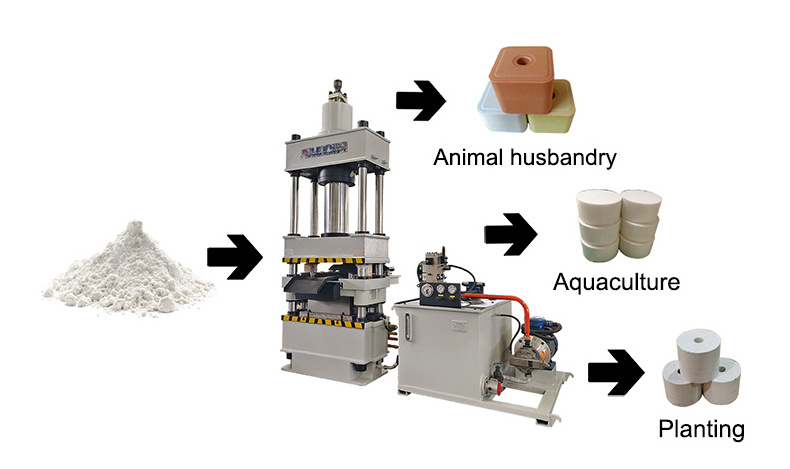

Fully automatic powder forming hydraulic press is mainly used for pressing powder metallurgy, electronic ceramics, rare earth powder, silicon carbide, ferrite magnetic materials and PTFE, diamond, graphite and other products, and can be widely used in automobiles, motorcycles, machine tools, household Electrical appliances, textile machinery, power generation equipment, aviation and many other industries.

Product Details

Technical features:

riveting hole is opened for the middle cylinder connecting plate, and the mortise and tenon filling welding is made. The weld is more full and more firm, and the deformation is reduced.

2,The overall box body mortise and tenon welding, steel plate thickness of more than 16MM, groove, each weld is welded more than 3 times. The column is made of 45# steel, the surface is plated with hard chrome, the four-column guide sleeve is made of wear-resistant material, and the thin oil centralized lubrication system is used to reduce friction resistance.

3,Finish milling the plane and ensure high strength pressure of the equipment. Mortise filling welding. Finish milling the plane after welding. Steel plate welding groove, make the workpiece more firm, reduce deformation. The inner wall of the cylinder is rolled to ensure the smoothness and hardness of the inner wall and prolong the service life.

Products Parts

Hot-sale Products

Company Introduction

Certifications

Exhibition And Customers

Packaging Shipping

Package and shipping:

1.The four column metal stamping press machine surface with anti-rust treatment,

2.The four column metal stamping press machine inner layer of plastic waterproof packaging,

3.The four column metal stamping press machine outer layer of thick wood or steel frame fixed,And then use a synthetic board package. Combined container transport, or separate container transport.

1.The four column metal stamping press machine surface with anti-rust treatment,

2.The four column metal stamping press machine inner layer of plastic waterproof packaging,

3.The four column metal stamping press machine outer layer of thick wood or steel frame fixed,And then use a synthetic board package. Combined container transport, or separate container transport.

Hot Searches