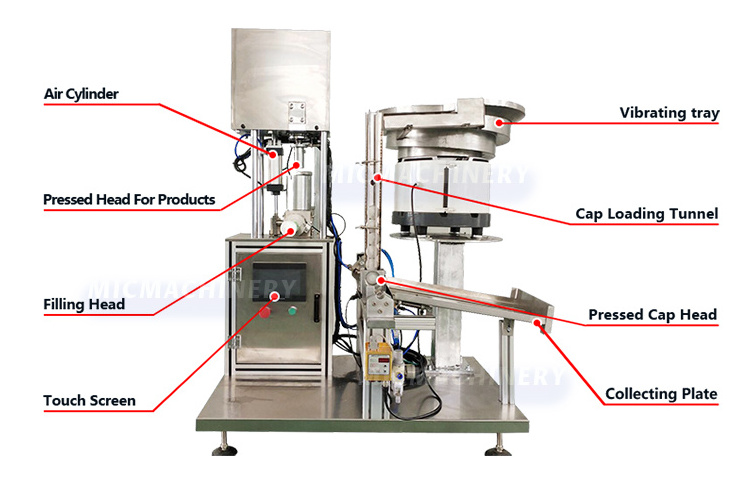

Air cylinder control the pressing head to press the silicone sealant from the metal pipe into the plastic cartridge.

- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

>=99%

-

Packaging Type:

-

cartridge, tube

-

Voltage:

-

220/380V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Micmachinery

-

Dimension(L*W*H):

-

1230*700*1400mm

-

Weight:

-

230 KG

-

Product name:

-

Semi automatic cartridge filling machine

-

Suitable for:

-

High Viscous Products

-

Capacity:

-

10-20 pcs/minute

-

Material:

-

Stainless Steel 304/316

-

Filling range:

-

100ml-300ml, 300ml-600ml, etc

-

Control:

-

PLC+ Touch Screen

-

Feature:

-

High Precision Filling Level

-

Certification:

-

CE Certificate

-

Advantage:

-

Easy Operation High Efficiency

-

Filling nozzles:

-

Single Nozzle

Quick Details

-

Machinery Capacity:

-

4000BPH, Other, 500BPH, 1000BPH, 100BPH, 200BPH, 1200bph

-

Packaging Material:

-

Plastic, Wood

-

Filling Material:

-

Silicone sealant, MS gel, PU glue, grease

-

Filling Accuracy:

-

>=99%

-

Packaging Type:

-

cartridge, tube

-

Voltage:

-

220/380V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Micmachinery

-

Dimension(L*W*H):

-

1230*700*1400mm

-

Weight:

-

230 KG

-

Product name:

-

Semi automatic cartridge filling machine

-

Suitable for:

-

High Viscous Products

-

Capacity:

-

10-20 pcs/minute

-

Material:

-

Stainless Steel 304/316

-

Filling range:

-

100ml-300ml, 300ml-600ml, etc

-

Control:

-

PLC+ Touch Screen

-

Feature:

-

High Precision Filling Level

-

Certification:

-

CE Certificate

-

Advantage:

-

Easy Operation High Efficiency

-

Filling nozzles:

-

Single Nozzle

PRODUCT DESCRIPTION

Semi automatic silica gel silicone sealant filling capping machine for silicone cartridge is designed for high viscosity material filling and capping. This machine is composed by hydraulic pressing system, filling control system and automatic capping system. Only one operator can control the whole machine. High filling accuracy, stable and reliable operation of the whole machine, no other pollution.

PRODUCT PARAMETER

|

Model

|

MIC-SFC20

|

|

Filling Volume

|

100-400ml

|

|

Weight

|

500kg

|

|

Machine Size

|

1100*800*1600mm

|

|

Suitable cartridge

|

φ40-50mm Length 150-230mm

|

|

Filling Speed

|

10-30pcs/min

|

|

Filling Nozzle

|

1

|

|

Material

|

Surface: SUS304

|

|

Air Pressure

|

5-8kg/m³

|

|

Precision

|

±0.5%

|

PRODUCT APPLICATION

DETAILED IMAGES

Pressing head

Rotary valve filling system

Using rotary valve, suitable for filling high viscosity product, such as silicone sealant& grease.

Advantage:

1.Improve filling accuracy;

2.Approach filling capacity.

Vibrating plate

Vibrating plate is used to sort and feed the plastic cap to capping station through cap loading guide rail in orderly.

Filling head

Products will output from this nozzle, the nozzle mouth diameter will according to cartridge diameter customized

Cap loading tunnel

Sorting out caps from vibrating tray, through the tunnel one by one

Cap pressing station

Manually put the cartridge on the station then the cap pressing head will press the cap into the bottom position of the cartridge without air. And finished cartridges will be collected on the collection plate.

PRODUCT REAL SHOT

RELATED PRODUCTS

COMPANY INTRODUCTION

FAQ

Hot Searches