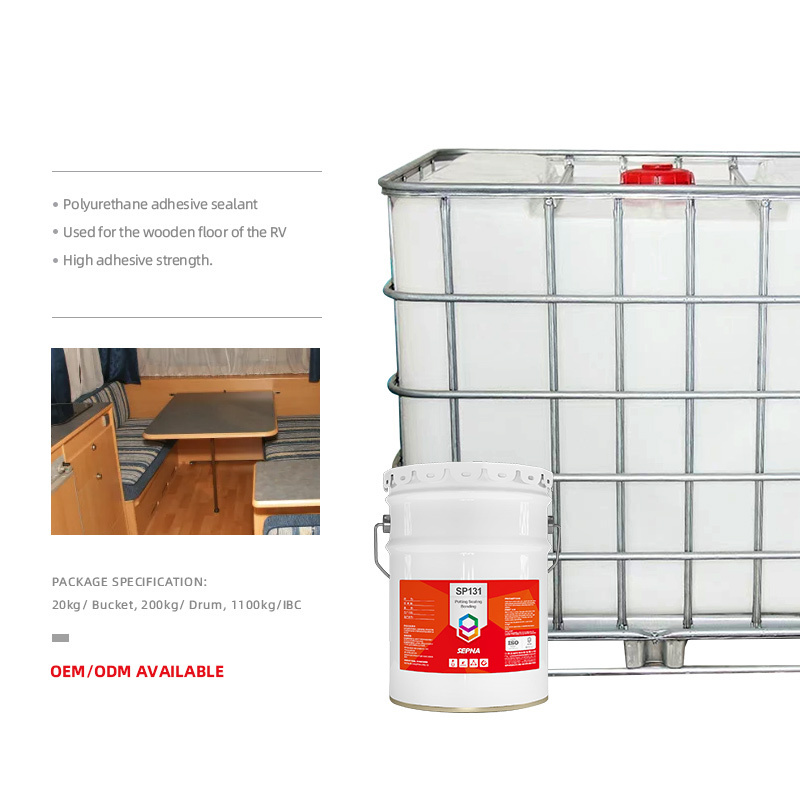

It is used primarily for bonding

sandwich panels

with

skin materials of pre-treated or primed aluminum, steel, glass fiber reinforced plastic and core materials of plywood, wood, extruded / expanded polystyrene and mineral wool.

- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

210-898-8

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

SEPNA

-

Model Number:

-

SP131

-

Type:

-

Single component, Single component

-

Color:

-

white/grey/black

-

Material:

-

Modified polyether

-

Application:

-

Au

-

Advantage:

-

high bonding strength

-

Certificates:

-

CE,,ISO9001 MSDS

-

OEM & ODM:

-

Free OEM & ODM service

-

Samples:

-

Free samples

-

Packing:

-

310ml cartridge/ 600ml sausage

Quick Details

-

CAS No.:

-

9009-54-5

-

Other Names:

-

one-component polyurethane adhesive

-

MF:

-

CH3H8N2O

-

EINECS No.:

-

210-898-8

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

SEPNA

-

Model Number:

-

SP131

-

Type:

-

Single component, Single component

-

Color:

-

white/grey/black

-

Material:

-

Modified polyether

-

Application:

-

Au

-

Advantage:

-

high bonding strength

-

Certificates:

-

CE,,ISO9001 MSDS

-

OEM & ODM:

-

Free OEM & ODM service

-

Samples:

-

Free samples

-

Packing:

-

310ml cartridge/ 600ml sausage

Our Products

Typical Applications

This product is suitable for experienced professional users only. Tests with actual substrates and conditions have to be

performed, ensuring adhesion and material compatibility

Product Description

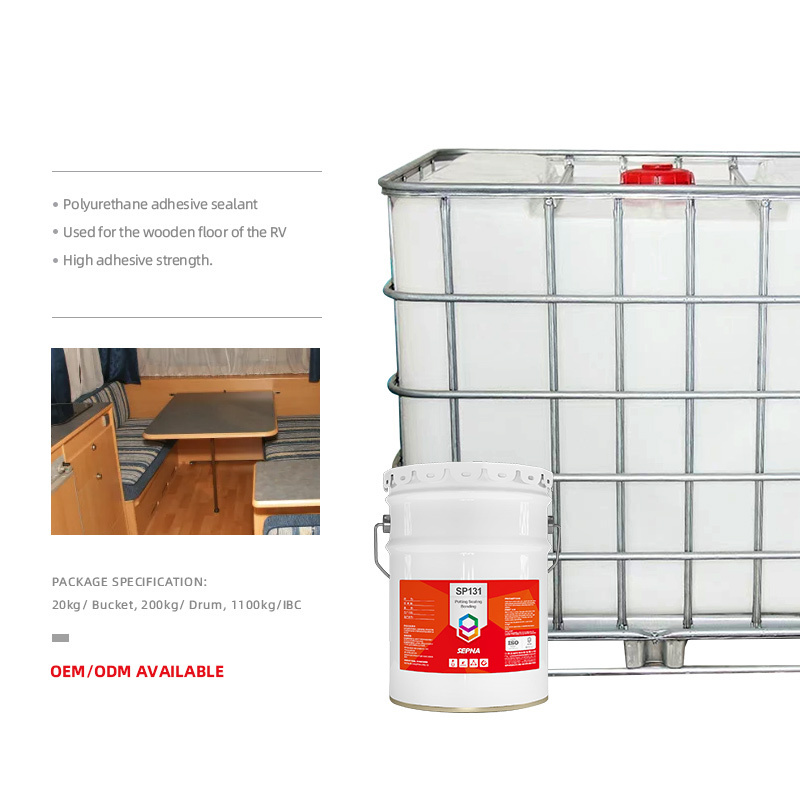

SP131

is a foaming, moisture curing, one-component polyurethane adhesive for bonding sandwich panels and similar constructions of various materials. In the process of curing,

it will foam and expand to make the uneven surface level.

SP131

1-component adhesive for panel bonding

Product Advantages

Solvent free

1.

Easy to use, pumpable,

and less consumption

2.

High expansivity, high strength and good filling and leveling to bonded substrate

3.

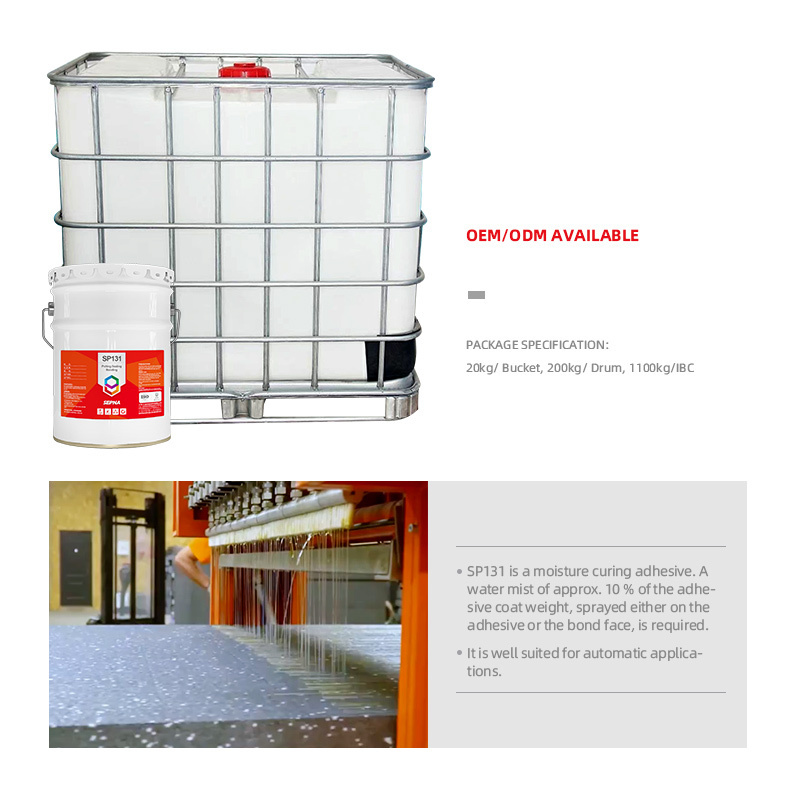

It is well suited for automatic applications

Low cost, high strength

sprayed either on the adhesive or the bond face, is required.

5.

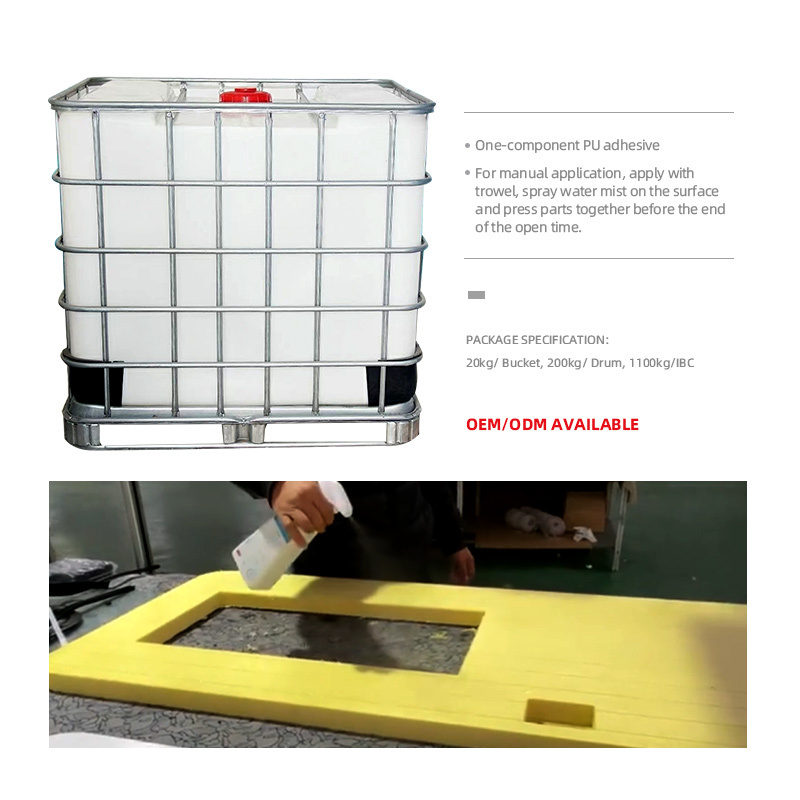

For manual application, apply with trowel, spray water mist on the surface and press parts together before the end of the open time.

High adhesive strength

8.

SP131

is a foaming, moisture curing PU adhesive

Typically a coat weight between

100

and

300 g/m2

is applied

Technical Data Sheet

|

PROPERTY

|

STANDARD

|

SP131

|

||

|

Chemical basis

|

-----

|

Polyurethane

|

||

|

Color

|

Visual inspection

|

Brownish yellow liquid

|

||

|

Curing mechanism

|

Moisture

|

Moisture curing

|

||

|

Viscosity / mPa.s

|

GB/T 10247-2008

|

2500±500

|

||

|

Solid content /%

|

100%

|

Good, no sagging

|

||

|

Solid content

|

%

|

100

|

||

|

Open time

|

GB/T 10247-2008

|

20 mins

|

||

|

Curing time

|

GB/T 10247-2008

|

45 mins

|

||

|

Application temperature

|

GB/T 20028-2005

|

15-30℃

|

||

|

Tensile shear strength

|

Aluminum –aluminum

|

>2 Mpa

|

||

|

Shelf life

|

5~25°C, month

|

6

|

||

|

Note:The above data are all recorded in standard environment after

7

days when the samples are totally curing . standard environment:

23 ℃, 50%

RHHTest data at

23 ℃

and

50 %

RH.

|

|

|

||

Delivery Time

|

Lead Time

|

Quantity (

KGS

)

|

1-3000

|

3001-10000

|

10001-50000

|

>50000

|

|

|

Est. Time (

Days

)

|

7

|

10

|

15

|

To be negotiated

|

Samples : Expree ( FedEx, DHL, TNT, UPS etc.)

Cargo : By Sea ( FCL / LCL), By Air, By Railway etc .

Cargo : By Sea ( FCL / LCL), By Air, By Railway etc .

Hot Searches