- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

TMOK

-

Standard or Nonstandard:

-

Standard

-

Main material:

-

Hpb 58-3 brass

-

Name:

-

Brass Check valve

-

In Stock:

-

Yes

-

Small order:

-

50,100 pcs ok

-

Working Temperature:

-

-10-110℃

-

PN:

-

16

-

Certificate:

-

ISO 9001:2015

-

Free Sample:

-

Yes

-

Working medium:

-

Water

Quick Details

-

Port Size:

-

1/2"-4" DN15-DN100

-

Place of Origin:

-

Zhejiang, China

-

Model Number:

-

TK-401

-

Brand Name:

-

TMOK

-

Standard or Nonstandard:

-

Standard

-

Main material:

-

Hpb 58-3 brass

-

Name:

-

Brass Check valve

-

In Stock:

-

Yes

-

Small order:

-

50,100 pcs ok

-

Working Temperature:

-

-10-110℃

-

PN:

-

16

-

Certificate:

-

ISO 9001:2015

-

Free Sample:

-

Yes

-

Working medium:

-

Water

Why Choose Us

Product Paramenters

|

Certificates:

|

ISO9001/CNAS/TUV/SGS/CE/ACS/WRAS

|

|

Brass Material

|

Brass(CuZn39Pb3, CZ121, C37710, CW614N, CW617N, DZR, etc)

|

|

Surface

|

Natural brass/Nickel plated /Chroming

|

|

Ball Material

|

Chrome Plated Brass/Iron can be customized if needed

|

|

Handle Material

|

Steel

|

|

Body Seal Material

|

PTFE

|

|

Connection Type

|

|

|

Sample Time

|

1-3 days for Packing and 10 days for delivery by Fedex/DHL/UPS/TNT

|

|

Packing

|

opp bag inner, inner box, out carton and pallet.

|

|

Test Pressure

|

12 bar/174 psi

|

|

Working Temperature

|

-20℃ to +120℃/4℉ to 248 ℉

|

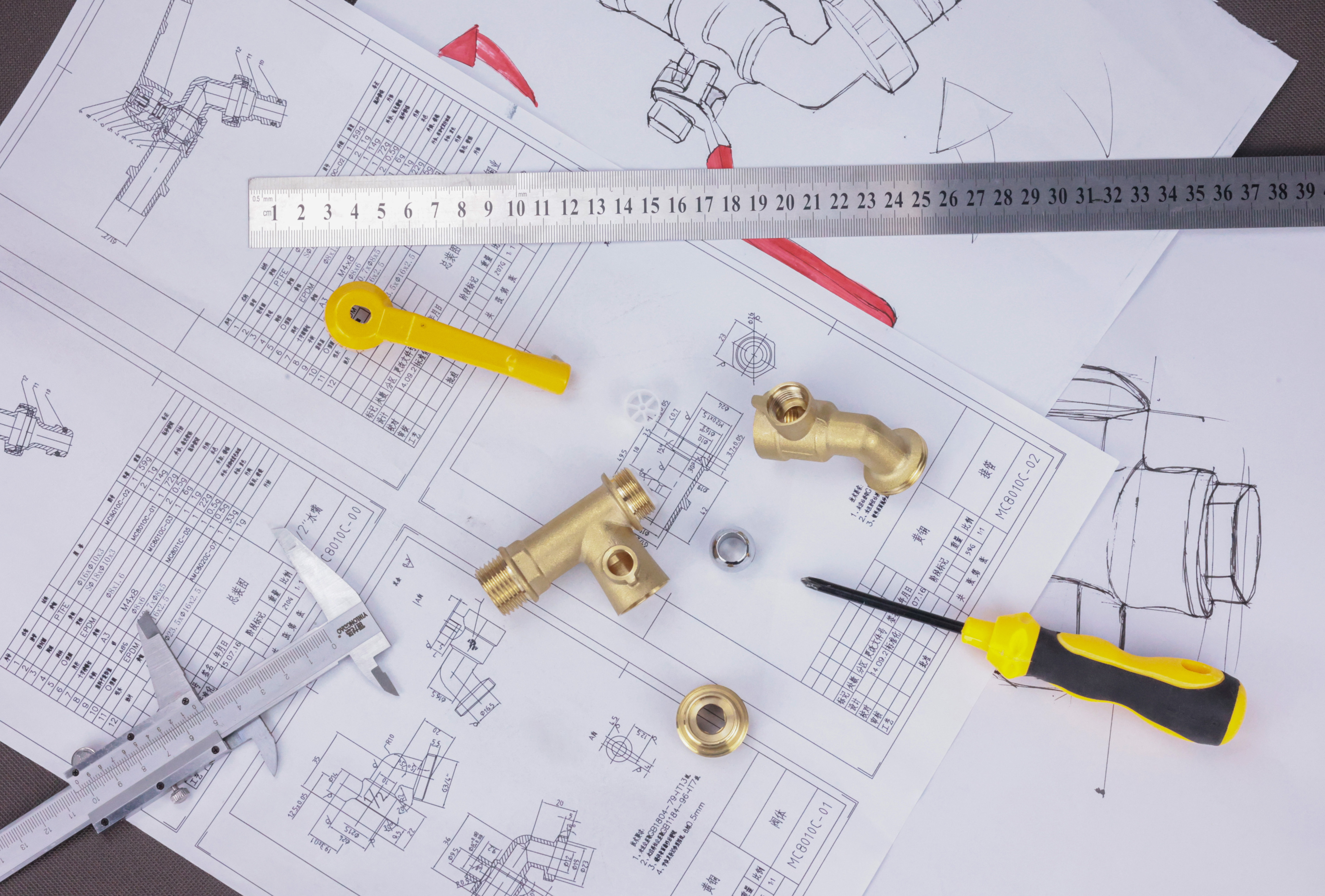

Details Images

What is a Swing Check Valve?

A swing check valve allows forward flow and blocks the reverse flow. It provides a strong option for uni-directional homogenous flow applications. In this article, you will review a swing check valve diagram, operating principles, types, k-values,installation concerns, and applications.

Brass Swing Check Valve

Size:1/2"-4" Material:Brass(CuZn39Pb3) BSP

How does a Swing Check Valve work?

The swing check valve’s disc and the rocker connect, allowing them to revolve at an angle around the pin shaft. When input pressure to the disc exceeds resistance pressure, fluid flows in the prescribed direction. While the valve opens, the disc separates from its seat and rotates around the pin to a fully open position.

When the flow rate drops the valve disc will rotate back to the closed position. This prevents backward fluid flow.

Installation Concerns

Installation of check valves requires careful attention to the flow direction. Improper installation of a swing check valve can result in catastrophic failure.

Due to the pressure requirements for proper functioning, the most frequent swing check installation is in a horizontal position.The horizontal position provides a simple installation as it eliminates gravity as an additional factor.

Due to the pressure requirements for proper functioning, the most frequent swing check installation is in a horizontal position.The horizontal position provides a simple installation as it eliminates gravity as an additional factor.

Applications

Swing check valves can regulate and transport water, steam, oil, nitric acid, acetic acid, solid oxidizing medium, and other corrosive media. They usually install in pipelines for petroleum, chemicals, and water-based process flows. They suit clean fluid, not solid-particle-laden or viscosity-intensive media.

Swing check valves are a standard solution in a variety of industries. Power plants, gas transmission, and refineries frequently employ swing check valves. Swing check valves help prevent the improper flow of gas that could result in dangerous leaks or fires.

These valves see broad usage in gas pipelines – both in natural gas cleaning, distribution, and compression.

Since swing check valves work well with large, predictable flow, they are frequently used in wastewater treatment and water pumping.

Swing check valves are a standard solution in a variety of industries. Power plants, gas transmission, and refineries frequently employ swing check valves. Swing check valves help prevent the improper flow of gas that could result in dangerous leaks or fires.

These valves see broad usage in gas pipelines – both in natural gas cleaning, distribution, and compression.

Since swing check valves work well with large, predictable flow, they are frequently used in wastewater treatment and water pumping.

Generally, for clean process media, swing check valves offer good service.

For transporting heavier crudes, distillates, and viscous and heterogeneous material, a spring check valve offers better service than swing check valves. Additionally, intermittent flow can lead to a potential water hammer in the swing check valve. As a result, engineers typically prefer spring check valves for these applications.

For transporting heavier crudes, distillates, and viscous and heterogeneous material, a spring check valve offers better service than swing check valves. Additionally, intermittent flow can lead to a potential water hammer in the swing check valve. As a result, engineers typically prefer spring check valves for these applications.

Hot Searches