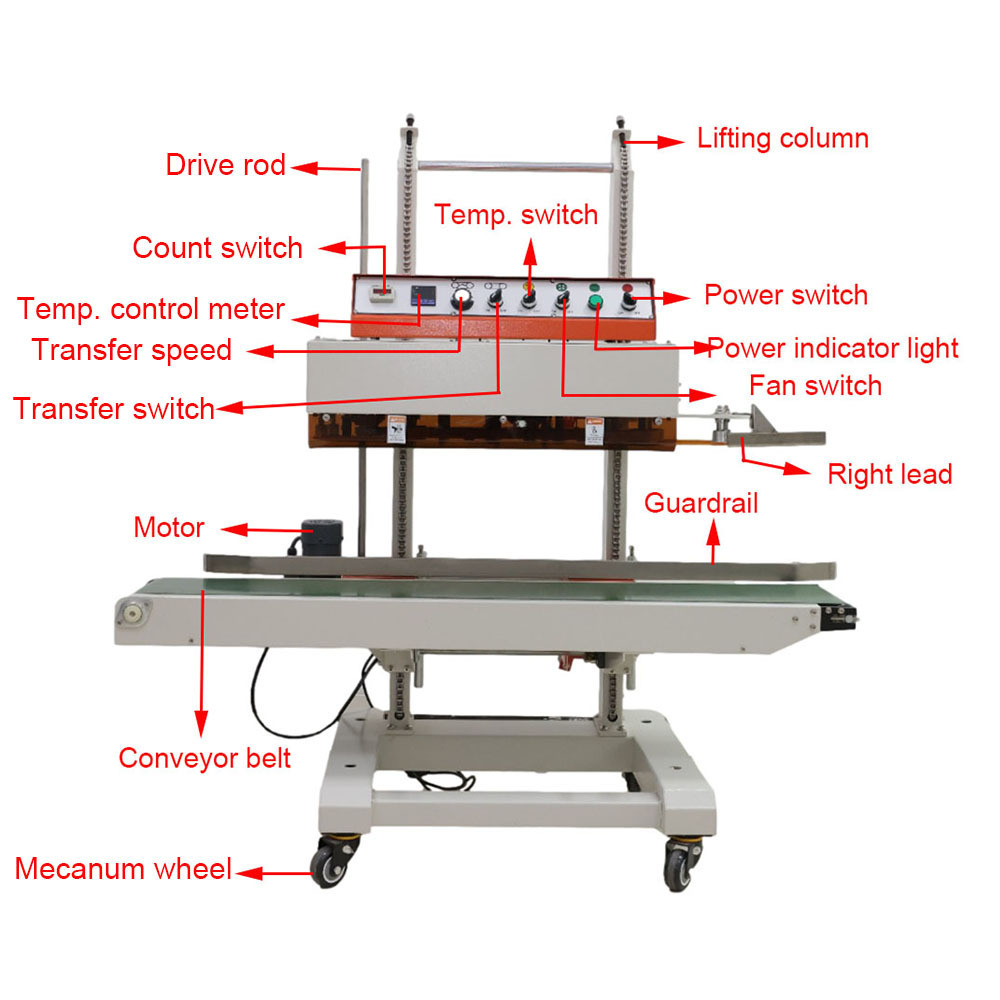

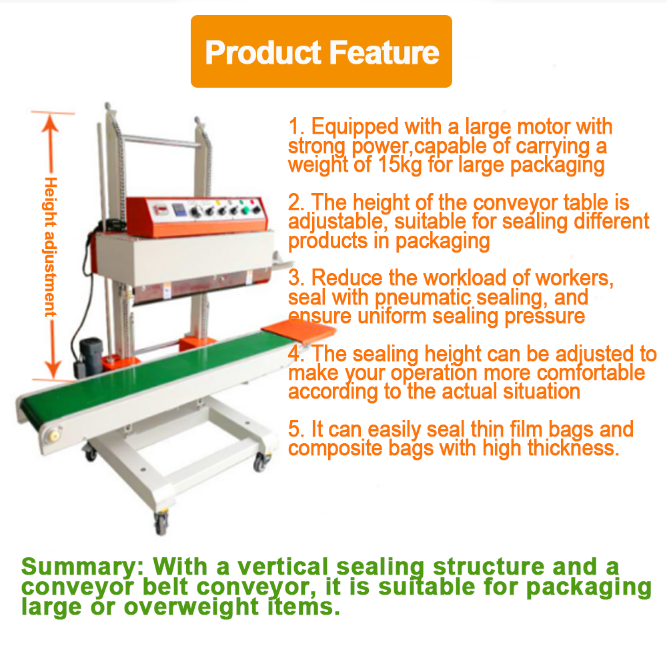

The automatic plastic film continuous sealing machine adopts electronic constant

temperature control and automatic conveying device, which can control various plastic film belts of different shapes and can be used together on various packaging assembly lines. Its sealing length is not limited. This sealing machine can be equipped with embossing and printing wheels, and the font can be changed as needed. It can also print the factory date, shelf life, shelf life, and other marks on the sealing surface. The sealing pattern and logo handwriting are clear and beautiful. The sealing and printing can be completed in one go, and the date and batch number can be changed as needed. It is convenient to use and complies with the food hygiene laws and regulations of the item. This automatic film sealing machine is suitable for sealing aluminum foil bags, plastic bags, composite bags in industries such as pesticides, food, daily chemicals, lubricants, etc. This equipment has strong sealing and high efficiency; Simple and compact structure with small volume; Beautiful appearance, advanced technology, and low power consumption; It has the advantages of convenient operation, maintenance, and is an ideal sealing machine. Vertical is suitable for packaging and sealing of liquid items.

- Product Details

- {{item.text}}

Quick Details

-

Max Speed:

-

0-20m/min adjustable

-

Voltage:

-

220V/50Hz

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

HD

-

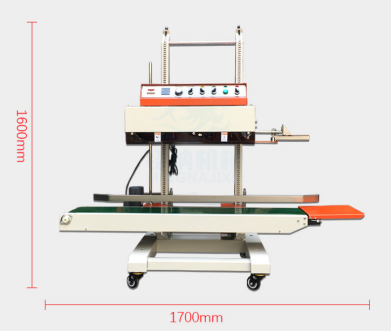

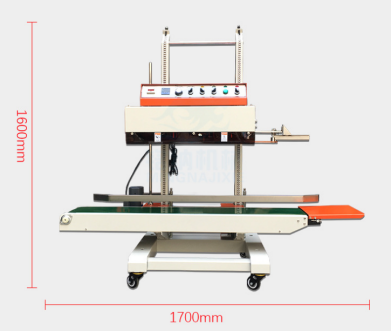

Dimension(L*W*H):

-

1700*750*1600mm

-

Weight:

-

130 KG

-

Product name:

-

Fully automatic vertical sealing machine

-

Model:

-

HD-1680

-

supply voltage:

-

AC220/50Hz

-

sealing speed:

-

0-20m/min adjustable

-

Packing width:

-

10mm

-

packing material:

-

Polypropylene composite film, polyester, polyethylene

-

film thickness:

-

0.02-1.00mm

-

temperature range:

-

0-300 degree

-

Packaging height:

-

50-800mm adjustable

-

Load capacity:

-

15KG

Quick Details

-

Packaging Type:

-

CANS, Bottles, Film, Pouch

-

Packaging Material:

-

Plastic, Paper, Glass

-

Driven Type:

-

Pneumatic

-

Max Speed:

-

0-20m/min adjustable

-

Voltage:

-

220V/50Hz

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

HD

-

Dimension(L*W*H):

-

1700*750*1600mm

-

Weight:

-

130 KG

-

Product name:

-

Fully automatic vertical sealing machine

-

Model:

-

HD-1680

-

supply voltage:

-

AC220/50Hz

-

sealing speed:

-

0-20m/min adjustable

-

Packing width:

-

10mm

-

packing material:

-

Polypropylene composite film, polyester, polyethylene

-

film thickness:

-

0.02-1.00mm

-

temperature range:

-

0-300 degree

-

Packaging height:

-

50-800mm adjustable

-

Load capacity:

-

15KG

Products Description

1680 continuous automatic vertical film sealing machine

|

Product name

|

Fully automatic vertical sealing machine

|

|

Model

|

HD-1680

|

|

supply voltage

|

AC220/50Hz

|

|

sealing speed

|

0-20m/min adjustable

|

|

Packing width

|

10mm

|

|

packing material

|

Polypropylene composite film, polyester, polyethylene

|

|

film thickness

|

0.02-1.00mm

|

|

temperature range

|

0-300 degree

|

|

Packaging height

|

50-800mm adjustable

|

|

Load capacity

|

15KG

|

|

heating power

|

400W/2pieces

|

|

Total power

|

1000w

|

|

sealing length

|

no limit

|

|

Count value

|

9999

|

|

Overall dimensions

|

1700*750*1600mm

|

|

Overall weight

|

130kg

|

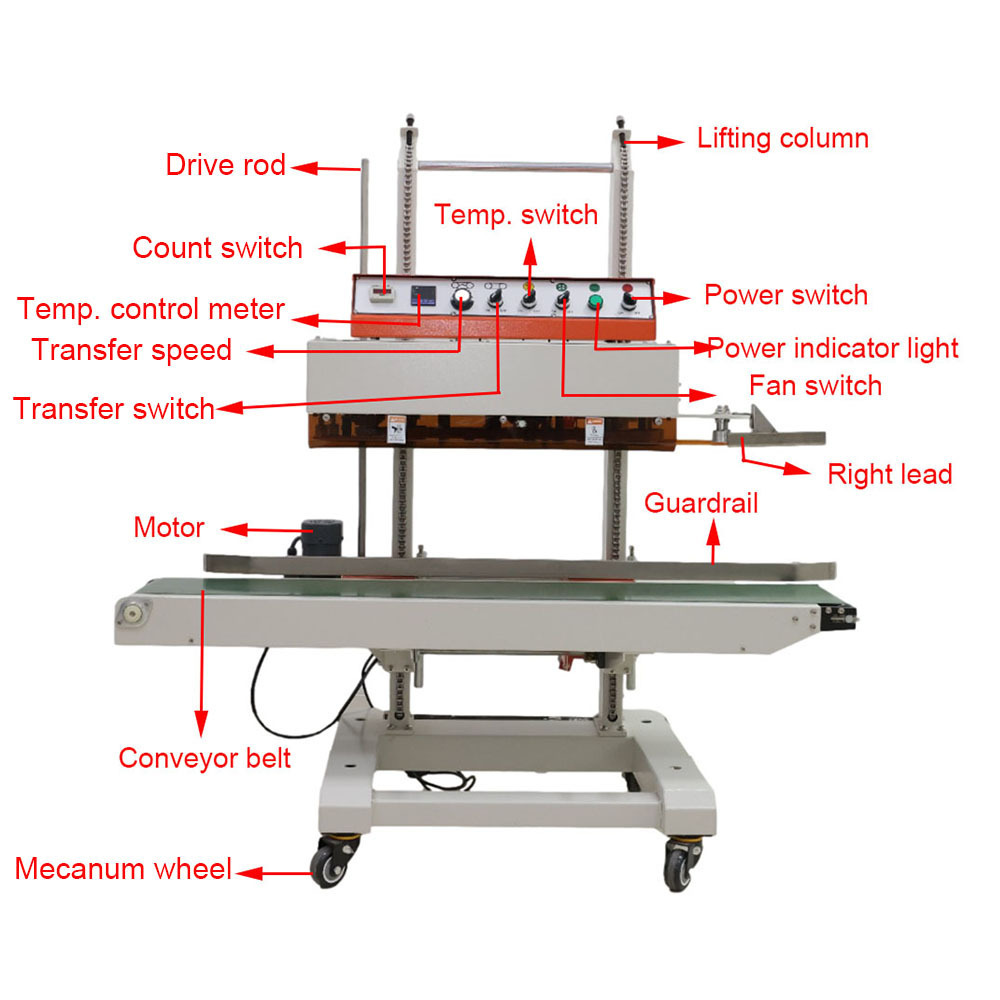

Simple panel operation

The operation panel is simple and beautiful, convenient and fast to use, with a counting function. The sealing temperature and conveying speed can be adjusted according to the actual situation.

Heating block

Using pure copper heating blocks, heating is uniform, heat dissipation and shaping are more uniform, making the sealing more complete, beautiful, and firm.

Motor

Increase the size of the motor, ensuring good stability and high efficiency in use

Suitable for vertical sealing of aluminum plastic paper and paper plastic composite bags

with a weight less than 15kg in chemical, grain, food, feed, etc

with a weight less than 15kg in chemical, grain, food, feed, etc

Recommended Product Introduction

Fully automatic 8-head paste liquid filling - rotating cap and screwing cap - double-sided labeling production line

The filling machine adopts piston pump and rotary valve, suitable for filling all kinds of thick & sticky material: In food industry like, tomato paste, chilli sauce, honey, butter, ketchup lunch meat, mayonnaise, marmadele, etc. The machine can be made with 4 filling heads/ 6 filling heads/ 8 filling heads/ 10 filling heads/ 12 filling heads ,16 filling heads, 18 filling heads

The filling machine adopts piston pump and rotary valve, suitable for filling all kinds of thick & sticky material: In food industry like, tomato paste, chilli sauce, honey, butter, ketchup lunch meat, mayonnaise, marmadele, etc. The machine can be made with 4 filling heads/ 6 filling heads/ 8 filling heads/ 10 filling heads/ 12 filling heads ,16 filling heads, 18 filling heads

etc, according to the filling capacity customers needed.

The capping machine is used to close all kinds of screw caps. People feed caps to bottle mouth by hand. Then 4 wheels move together to close the caps. It is widely used all kinds of bottles and caps with different materials in the chemical food, cosmetics and other industries.

The double-sided labeling machine is special-made machine, with total 2 labeling heads: flat two sides, which can label boxes or cans, and can also be used to label whole or half circles of round bottles.

For top sticker, it also label sticker with tail. It can also match the logos on the top sticker and on the side sticker. For example, shampoo in a flat bottle, laundry detergent on both sides.

The capping machine is used to close all kinds of screw caps. People feed caps to bottle mouth by hand. Then 4 wheels move together to close the caps. It is widely used all kinds of bottles and caps with different materials in the chemical food, cosmetics and other industries.

The double-sided labeling machine is special-made machine, with total 2 labeling heads: flat two sides, which can label boxes or cans, and can also be used to label whole or half circles of round bottles.

For top sticker, it also label sticker with tail. It can also match the logos on the top sticker and on the side sticker. For example, shampoo in a flat bottle, laundry detergent on both sides.

About HUIDE Machinery

We has gained recognition from the industry for its integrity, strength, and product quality. We has

several professional structural design engineers with strong new product development capabilities designing and manufacturing various types of filling and packaging equipment for customers.

several professional structural design engineers with strong new product development capabilities designing and manufacturing various types of filling and packaging equipment for customers.

Faced with fierce market competition, relying on our own advantages, integrating external resources optimizing internal management, continuously exploring and innovating, and making strides towards business specialization and diversified operations.

We adheres to the business philosophy of quality and service, wholeheartedly providing high-quality products and services to new and old customers, and meeting the needs of our customers to the greatest extent.

Serving customers, achieving customer success, "exploring and innovating, pursuing excellence" is the continuous pursuit of Guangzhou Huide. We sincerely look forward to cooperating with new and old customers to create a better future together!

Welcome you visit our factory to checking machine quality.

Welcome you visit our factory to checking machine quality.

1.

The total standardized workshop area to 2000 square meters.

2.

The equipment will be tested and run for 24 hours before leaving the factory, to ensure the smooth working of water pipeline,and pneumatic, electrical and mechanical stability.

3.

Adequate spare parts inventory ensures timely delivery and supply of spare parts.

4.

Engineers are experienced,

so that we can produce different products with different capacity and make reasonable flow chart satisfying customers' requirements to save space.

Customer Photos

Cooperative Customer Brands

Packaging and Delivery

FAQ

1.Q: Can I get a sample? How long for that?

A: Sure! We could offer 1 free sample and you need to pay the ship cost. It will take around 5-7 days.

2. Q: Can I make my own label or pattern?

A: Yes, we offer OEM and Customized service.

3. Q: Can I ask for custom products?

A: Sure, we own factory and designer to help you for design your products.

4. Q: How long is the production time?

A: Depends on the quantity your order.

5. Q: How is the packing?

A:We provide pearl white zipper bag, you could also chose paper box, cotton bag and blister packing.

Hot Searches